A load-sensing-based excavator swing energy-saving hydraulic system and control method

A rotary energy-saving and load-sensitive technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as increased fuel consumption, high power, and elevated hydraulic oil temperature, so as to reduce exhaust emissions, reduce fuel consumption, and change Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

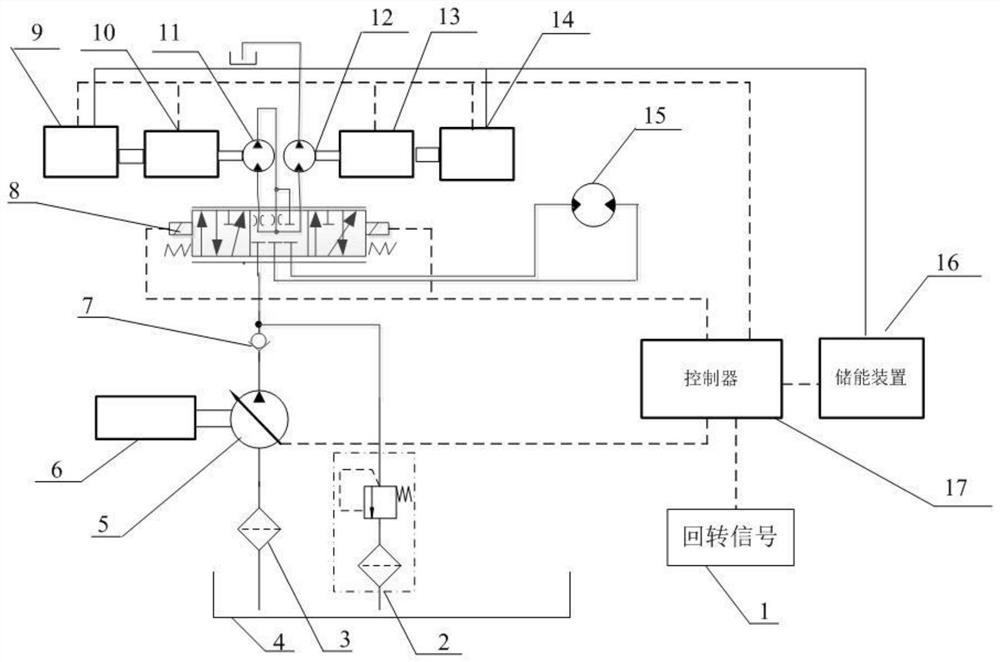

[0021] Load Sense (LS) refers to the load sensing system, which means that when there are multiple loads in the pressure coupling hydraulic system, in order to realize the flow distribution of each actuator during compound action, the hydraulic system uses the pressure of the maximum load as a feedback signal to control The pump provides the corresponding displacement, and at the same time uses pressure compensation to balance the pressure imbalance between the various actuators, so that the flow of different actuators can be independently distributed according to the control target, and the composite action of the actuators can be realized. At present, the excavator hydraulic system is mostly a load-sensing system, so the excavator slewing energy-saving technology based on the load-sensing system requires little modification to the original vehicle and is easy to implement. This load-sensitive excavator swing energy-saving hydraulic system uses energy conversion components to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com