Construction site drilling rig

A construction site and drilling rig technology, applied in construction, rotary drilling rigs, earthwork drilling and mining, etc., can solve the problems of inability to complete drilling work efficiently and quickly, single drill bit structure, and poor safety performance, so as to improve drilling efficiency , Reduce dust pollution and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

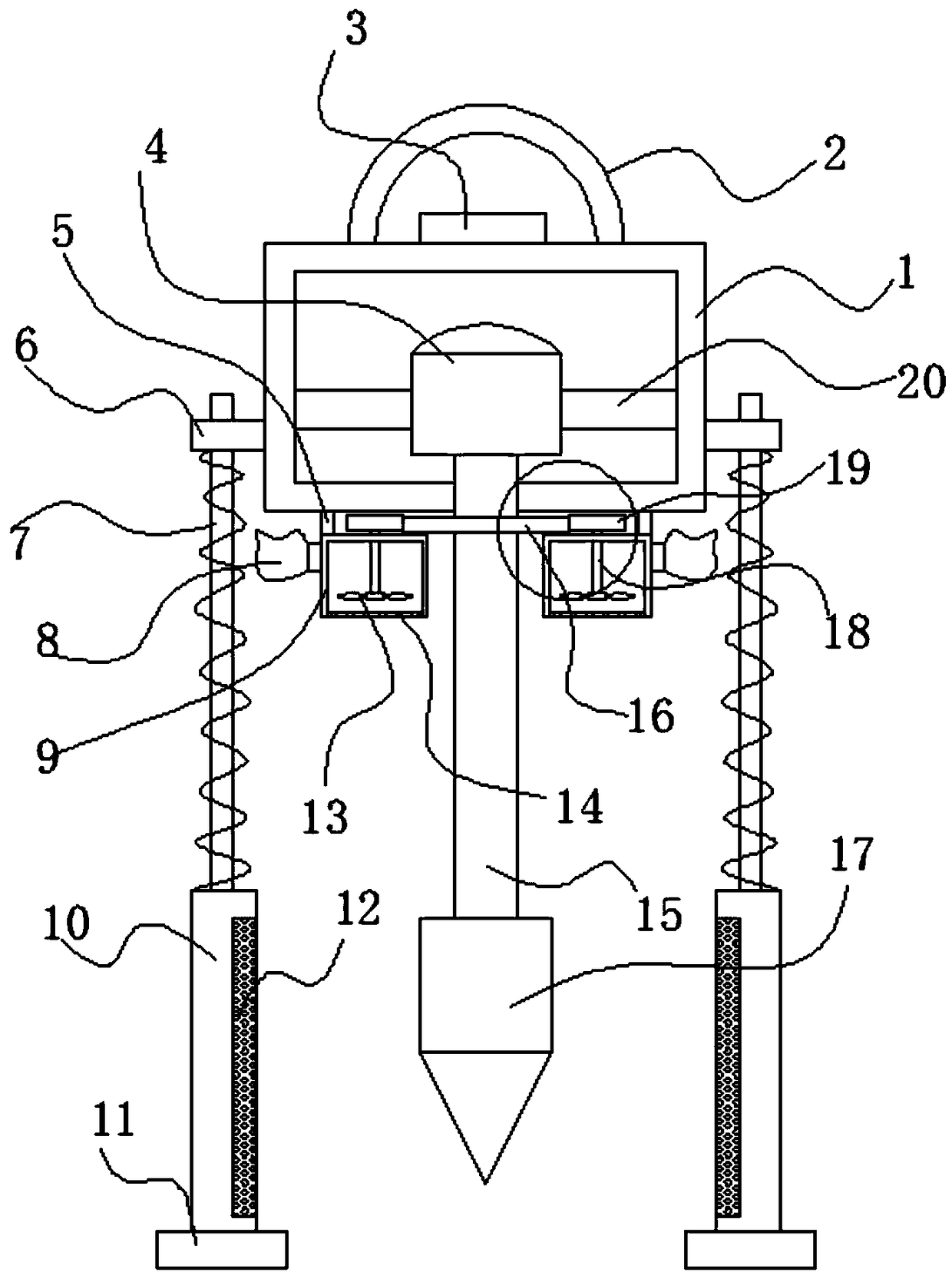

[0019] see Figure 1~3 , in an embodiment of the present invention, a drilling rig for a construction site includes a box body 1, a pull ring 2 is provided at the upper end of the box body 1, a drive motor 4 is provided inside the box body 1, and the drive motor 4 is electrically connected to control The button 3 and the control button 3 are located on the surface of the box body 1 below the pull ring 2. The drive motor 4 is connected and fixed with the inner wall of the box body 1 through the positioning rod 20. The output end of the drive motor 4 is provided with an output shaft 15, and the lower end of the output shaft 15 is provided with a A drill bit 17, the box body 1 is provided with a buffer guiding mechanism;

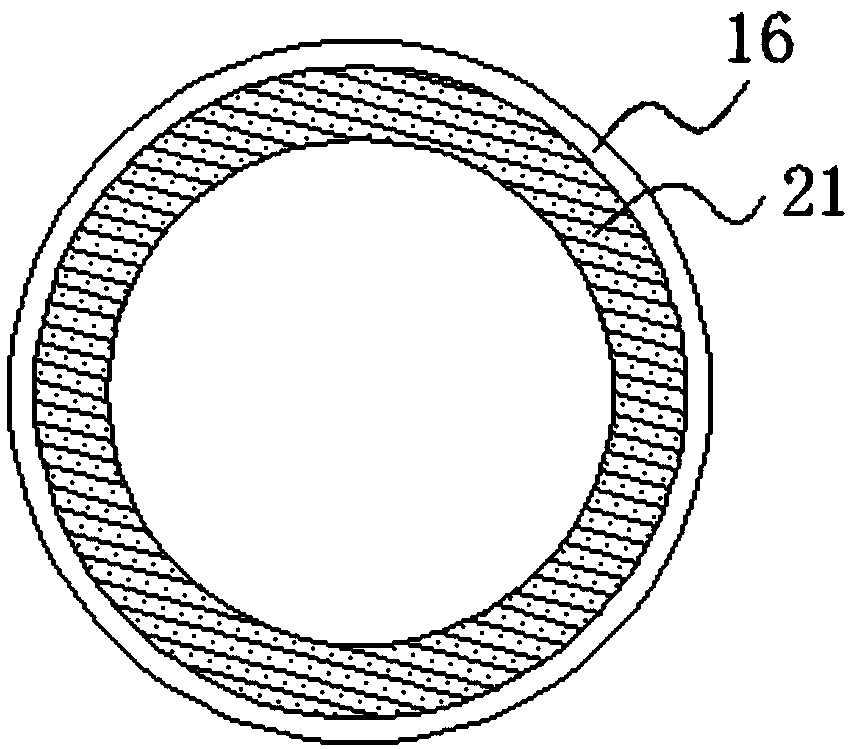

[0020] The buffer guide mechanism includes a cylindrical support cylinder 10, a support ring 11 is provided at the lower end of the support cylinder 10, and a rubber pad 21 is embedded on the lower end surface of the support ring 11, and three guide rods 7 are ...

Embodiment 2

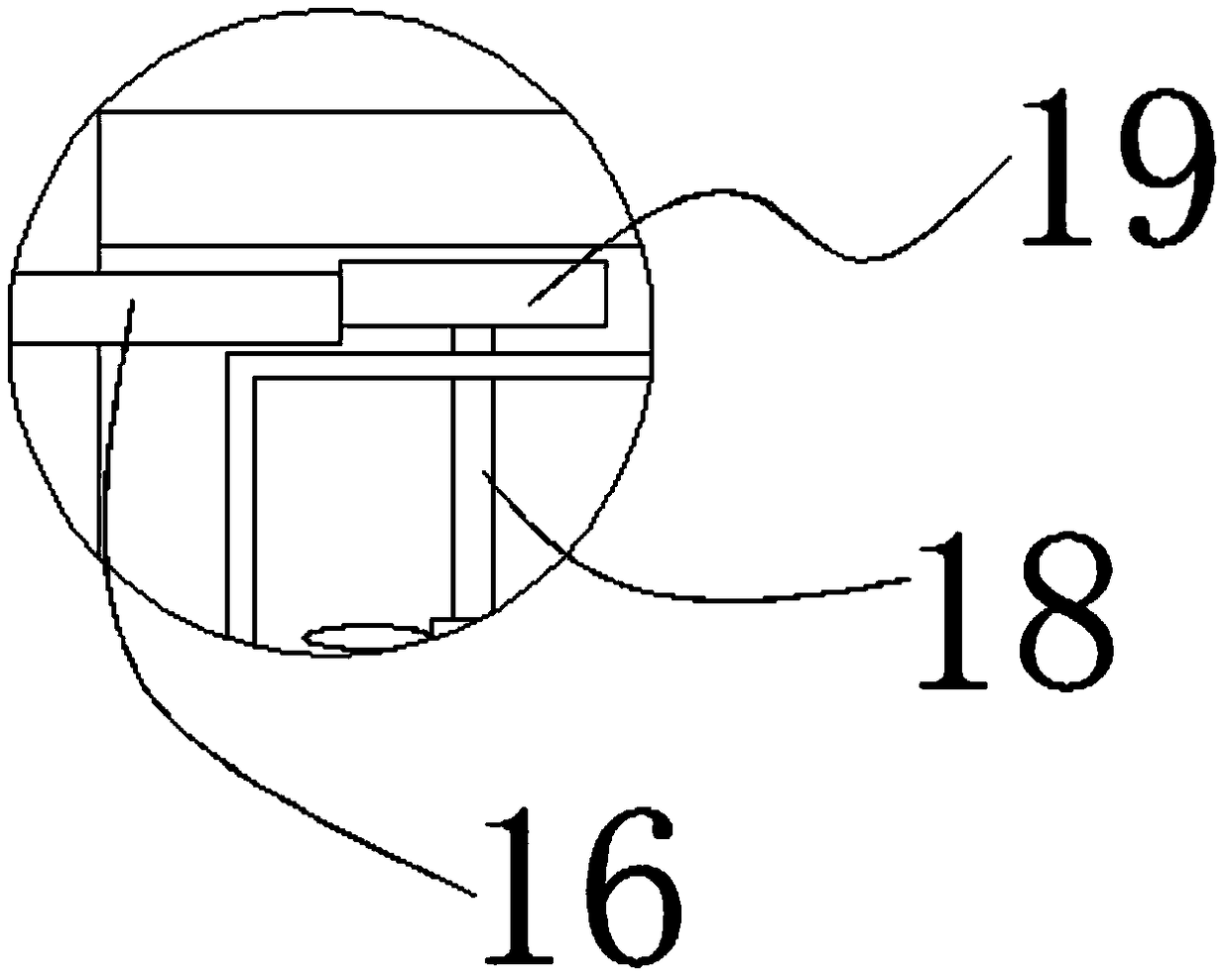

[0023] The difference from Embodiment 1 is that: the lower end surface of the box 1 is distributed with several air extraction boxes 9, the air extraction boxes 9 are connected and fixed with the box body 1 through the fixing rod 5, and the outside of the air extraction box 9 is provided with Exhaust port, detachable at the exhaust port is provided with a dust bag 8, the upper end of the suction box 9 is rotated to be provided with a rotating rod 18, and the upper end of the rotating rod 18 is provided with a driven gear 19, where the driven gear 19 is located. A drive gear 16 is provided on the shaft 15, and the drive gear 16 and the driven gear 19 mesh with each other. The lower end of the rotating rod 18 is provided with a fan blade 13, and the lower end of the suction box 9 is provided with a ventilation hole 14. When the device is in use , the output shaft 15 drives the driving gear 16 to rotate, the driving gear 16 drives the driven gear 19 to rotate, the driven gear 19 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com