Natural gas engine combustion organization method adopting manifold multiple-injection, pre-combustion chamber low-pressure gas supply and diesel oil micro-jetting ignition

A technology of multiple injection and pre-combustion chamber, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of unreasonable organization of stratified combustion, stable ignition research, lean mixture misfire and knocking, and slow flame propagation speed and other problems, to achieve the effect of improving misfire and knocking problems, improving combustion quality, improving economy and emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

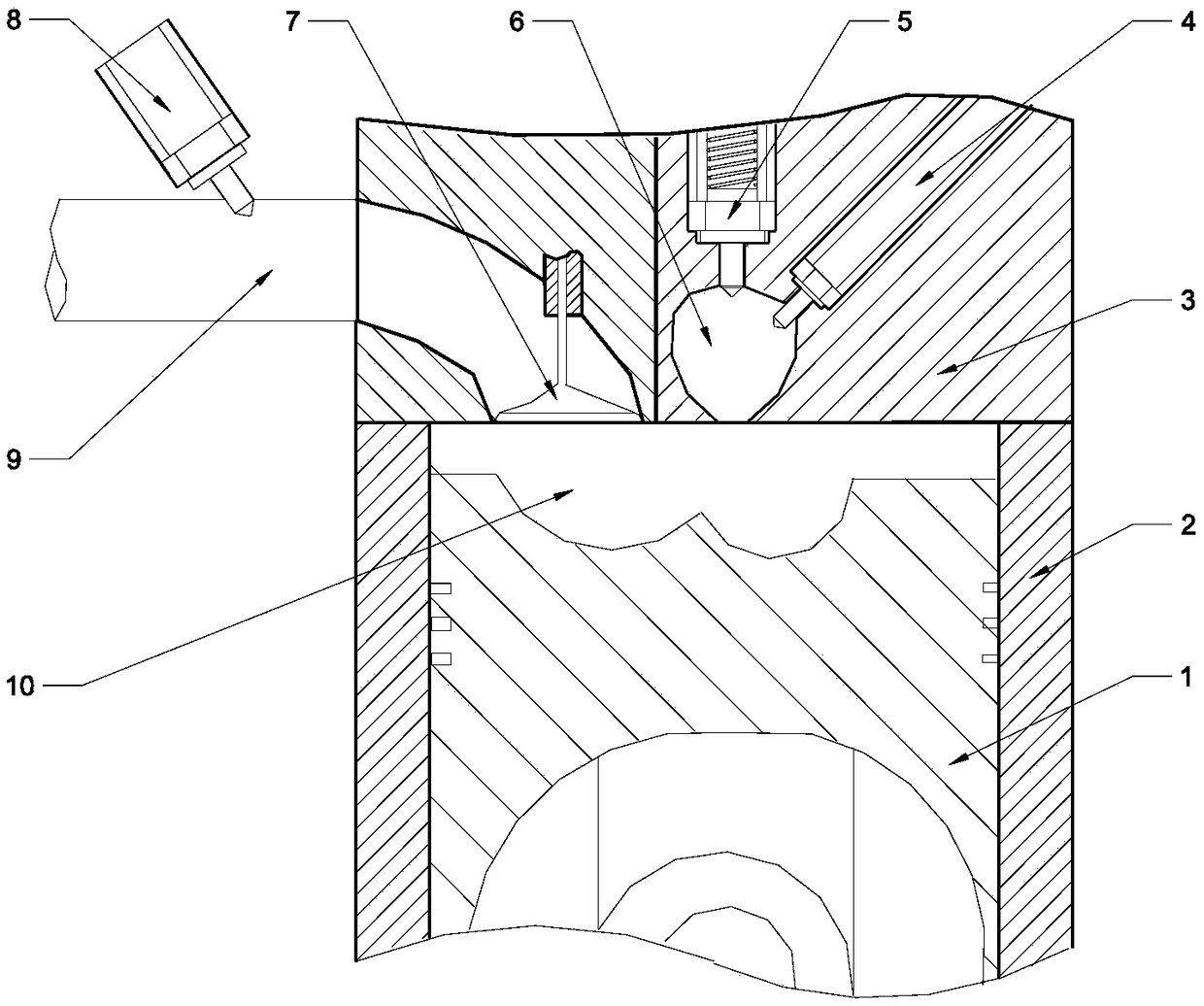

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

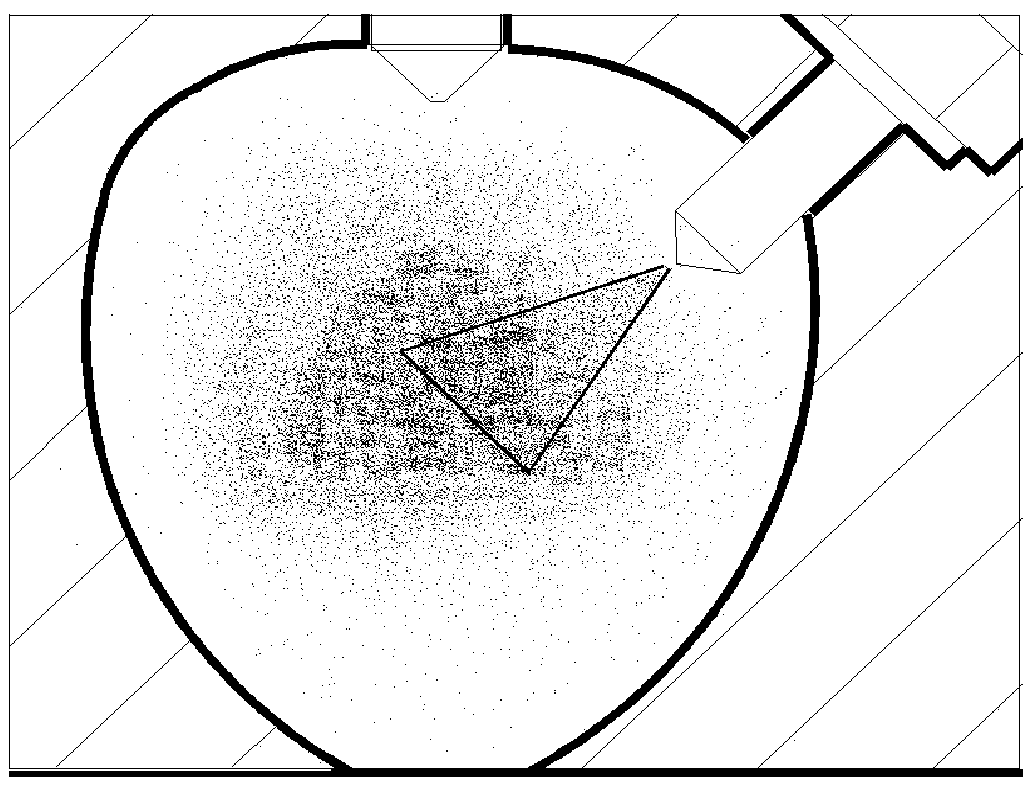

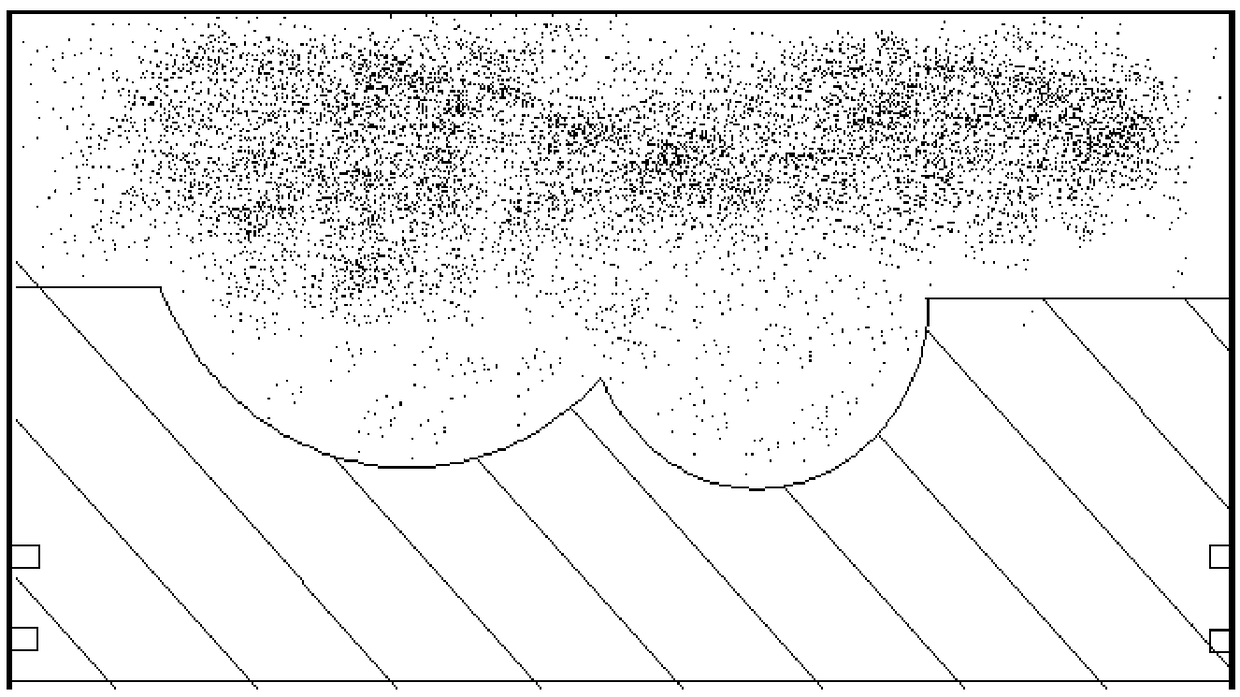

[0023] combine Figure 1-6 The structure of the combustion system of the natural gas engine with premixed micro-injection ignition and low-pressure air supply in the pre-combustion chamber includes: piston 1, cylinder liner 2, cylinder head 3, fuel injector 4, low-pressure one-way air supply device 5, pre-combustion Chamber 6, intake valve 7, manifold low-pressure gas injection device 8, intake passage 9, main combustion chamber 10. The main combustion chamber is composed of the upper surface of the piston, the peripheral wall of the cylinder liner and the lower surface of the cylinder head; the pre-combustion chamber is located in the cylinder head and adopts an oval structure with a wide top and a narrow bottom. The central axis of the pre-combustion chamber coincides with the central axis of the cylinder. The outlet is located at the center of the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com