Shaft, pump body component and compressor

A main body, short shaft technology, applied in pump components, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problems of reduced reliability, damage, component wear and other problems of compressors, and reduce eddy current phenomenon. , Improve the lubricating effect and the effect of increasing the oil volume of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

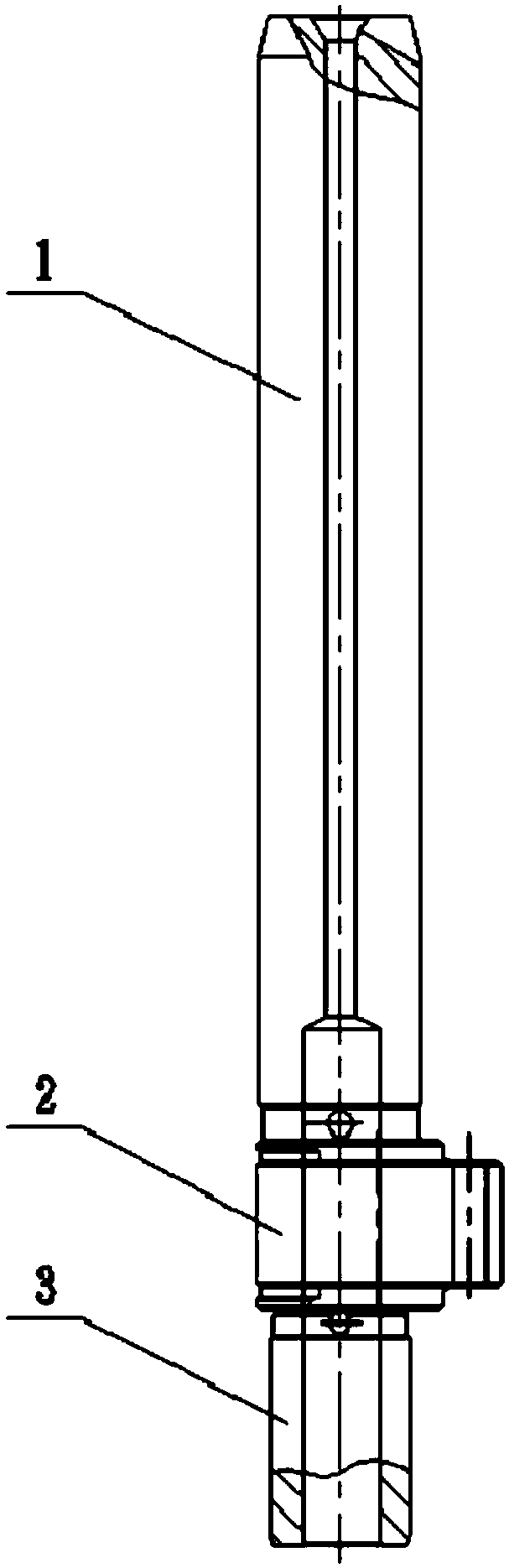

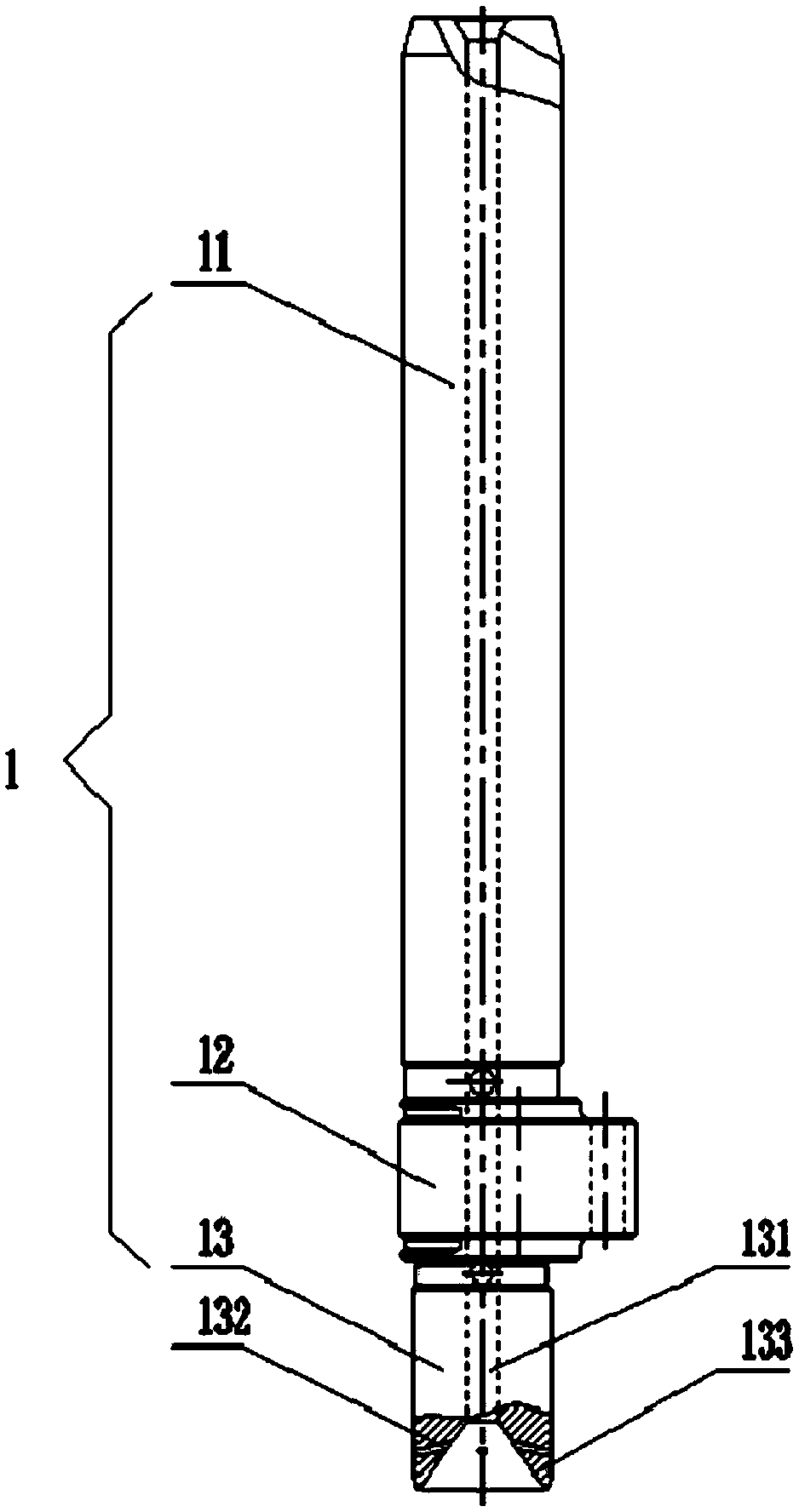

[0040] Such as figure 2 As shown, the present invention provides a shaft, including: a shaft body 1 and an oil pumping structure arranged on the shaft body 1 .

[0041] Such as figure 2 As shown, the first end of the central shaft body 1 of the present invention is placed in the lubricating medium 3, and the second end is connected to the rotating power source, which may be the output end of the rotating torque of the rotating motor.

[0042] Such as figure 2 As shown, the oil pump structure in the present invention includes an oil delivery main hole 131 arranged axially on the end face of the first end of the shaft body 1, and an outer circumference of the first end of the shaft body 1 Several enhanced oil pumping holes 132 are opened on the wall, and the first end of the enhanced oil pumping hole 132 communicates with the main oil delivery hole 131 , and the second end penetrates the outer peripheral wall of the first end of the shaft body 1 . In the present invention, t...

Embodiment 2

[0053] The present invention also provides a pump body assembly, including a crankshaft, which is the shaft in Embodiment 1.

Embodiment 3

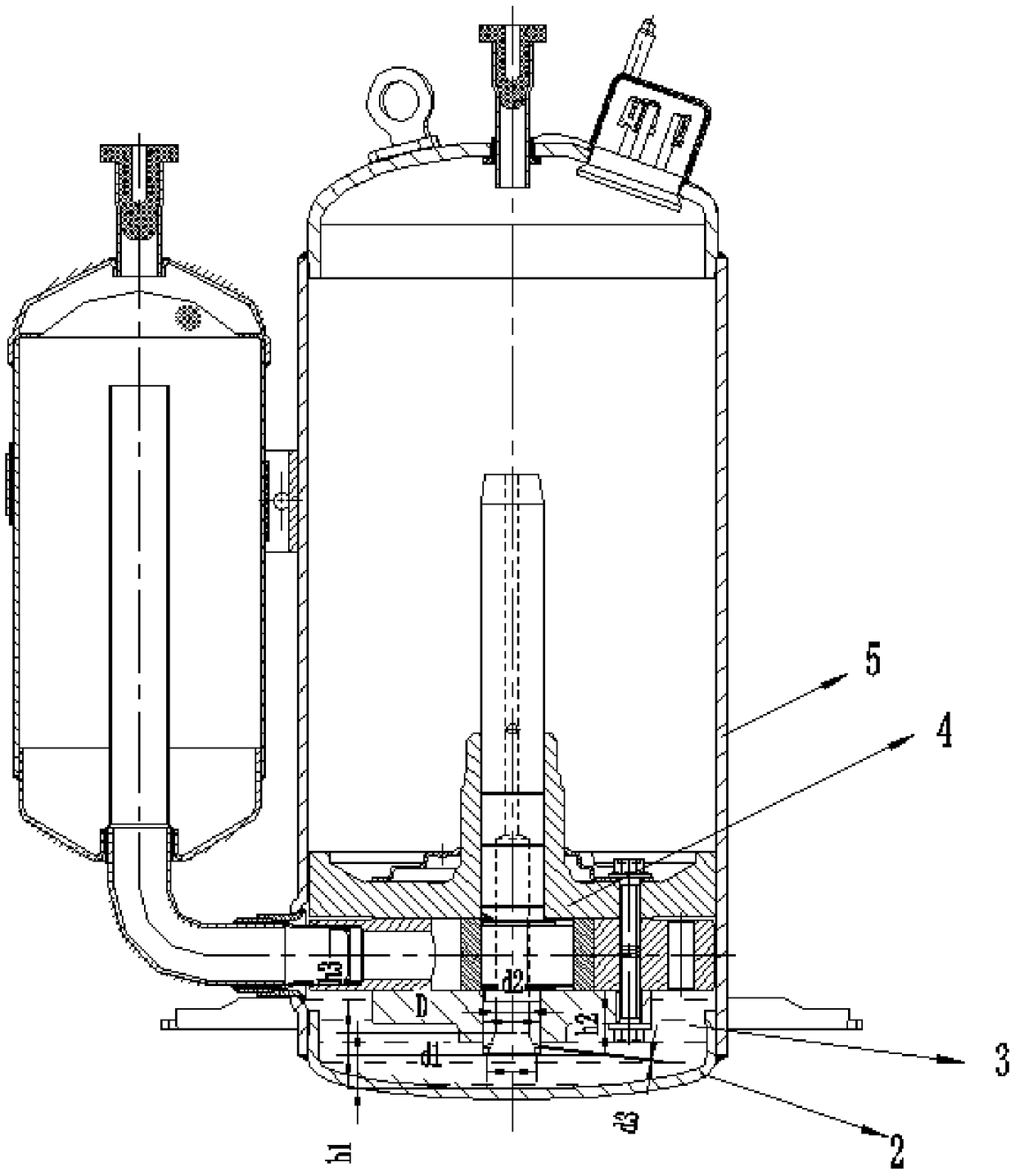

[0055] Such as image 3 As shown, the present invention also provides a compressor, including the pump body assembly 4 in Embodiment 2. It also includes a lower cover 2 and a housing 5 . The pump body assembly 4, the lower cover 2, and the housing 5 form a closed volume, and liquid lubricating oil is placed in the closed volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com