Fast pre-pressing device in limited space

A limited space, rapid technology, applied in the direction of threaded fasteners, connecting components, screws, etc., can solve the problems of vibration isolator failure, excessive deformation of rubber vibration isolators, vibration, noise, etc., to improve reliability and The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below with reference to the drawings and specific embodiments:

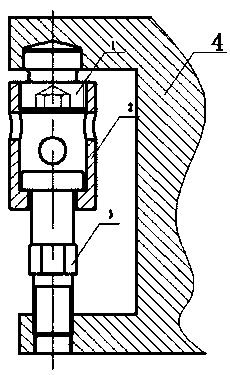

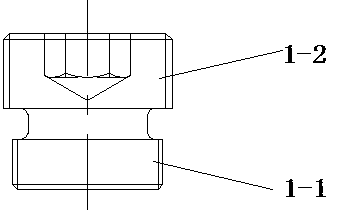

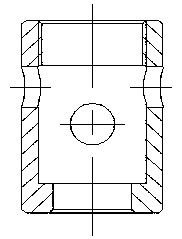

[0016] Such as figure 1 As shown, a rapid pre-compression device in a limited space is provided in a groove on the rubber isolator 4; the rapid pre-compression device has a short stud bolt 1, combined with figure 2 , The two ends of the short stud bolt 1 are the screw rod I1-1 and the screw rod II1-2 respectively; the screw rod I1-1 and the screw rod II1-2 are transitionally connected by a polished rod 1-3; the polished rod The diameter of 1-3 is smaller than the diameter of screw I1-1 and II1-2; the screw I1-1 described by the short stud bolt is threadedly connected with the screw hole on the side of the groove of the rubber isolator. The outer wall surface of the screw rod II has an external thread connected with the looper; the center of the screw rod II of the short stud bolt has a hexagonal hole for matching with an inner hexagon wrench; image 3 , The looper 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com