A device and method for testing the adhesion coefficient utilization rate of an automobile air pressure braking system

A technology of automobile braking system and air braking, which is applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc. It can solve the problem that the tester needs to stop many times and drill under the vehicle to adjust the adhesion coefficient. Utilization rate test device setting is unreasonable, test efficiency and test accuracy are not high, etc., to achieve the effect of low experience dependence, reduced operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

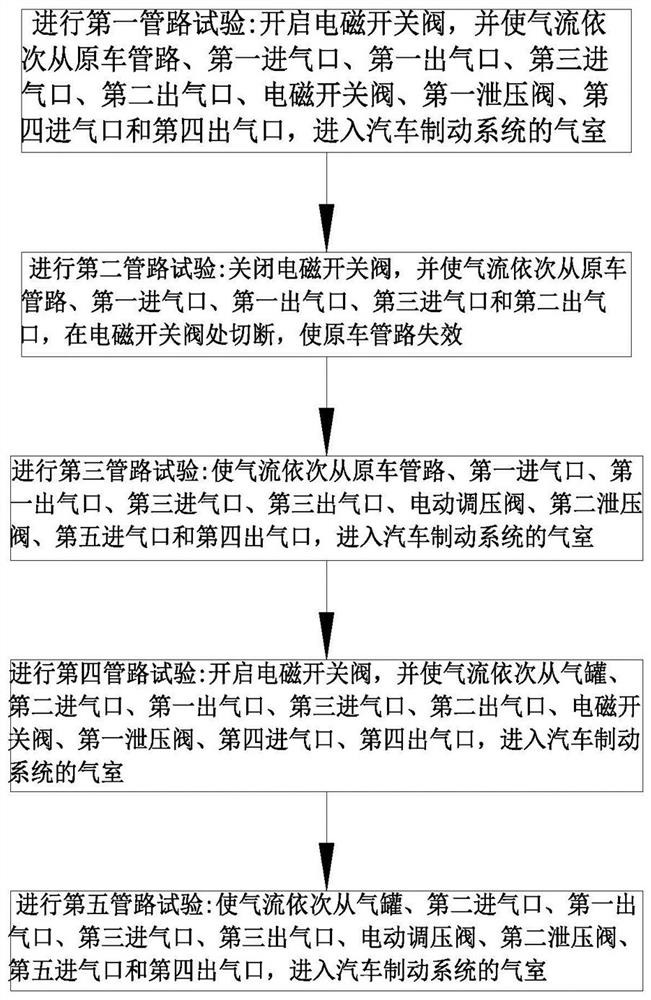

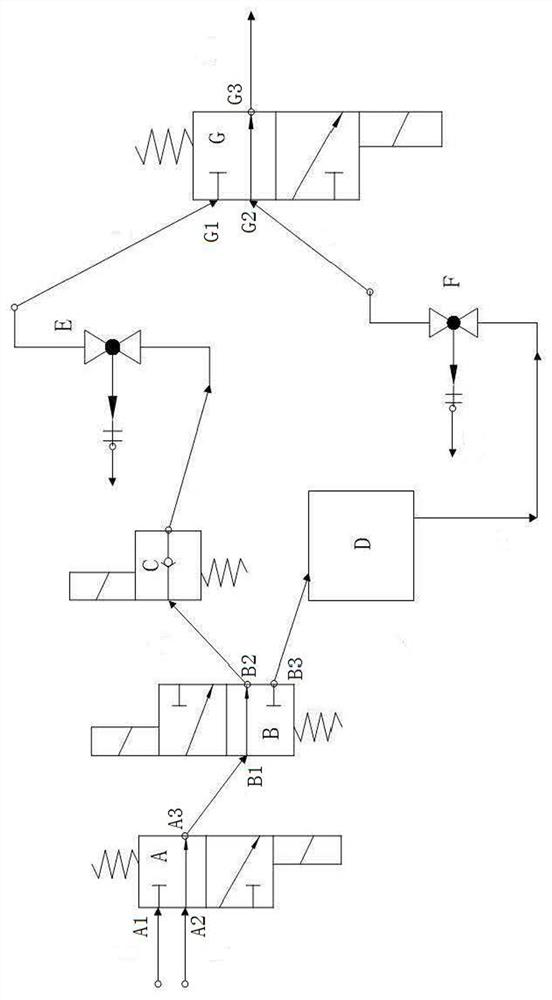

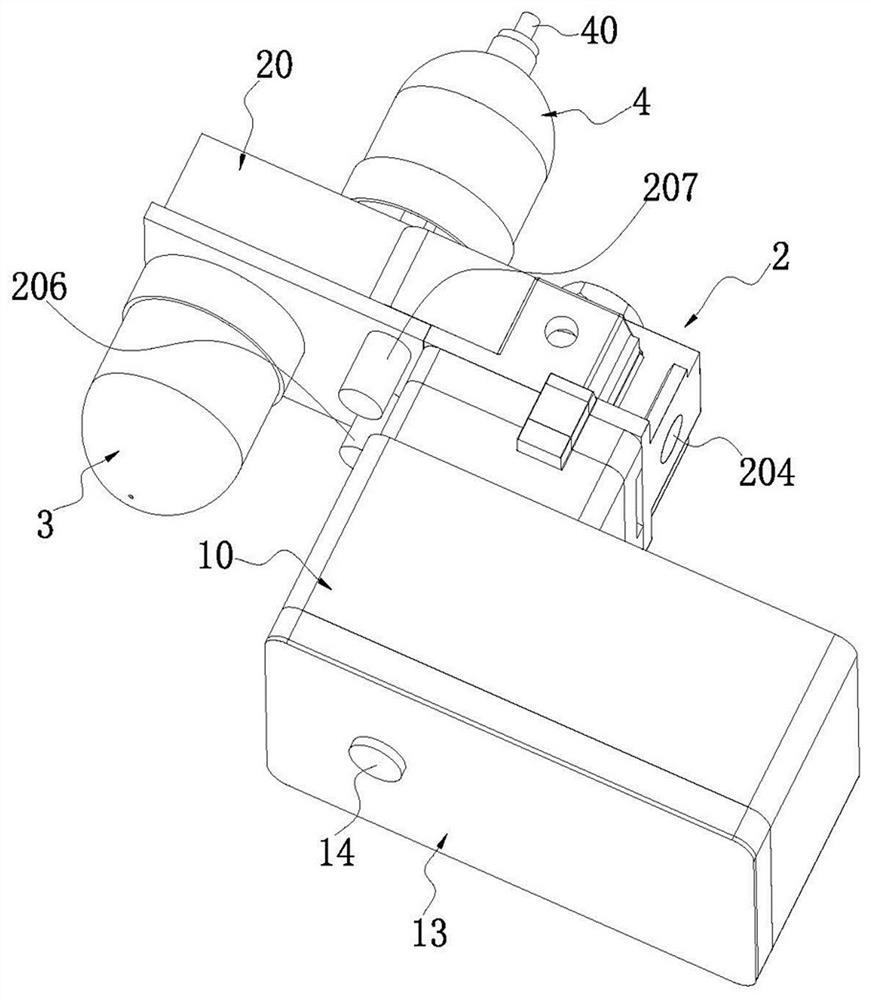

[0052] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0053] Such as figure 1 As shown, a test device for the utilization rate of the adhesion coefficient of the automobile air pressure braking system includes: an intake selection valve A, a pipeline cut-off valve B, an electromagnetic switch valve C, an electric pressure regulating valve D, a first pressure relief valve E, The second pressure relief valve F and the gas outlet selection valve G.

[0054] Intake selection valve A, the first air intake A1, the second air intake A2 and the first air outlet A3 are arranged on the air intake selection valve A; the first air intake A1 can be used for braking with the automobile The original vehicle pipeline of the system is connected, and the second air inlet A2 can be used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com