Pre-drilling in-situ rock mass combined measurement device and measurement method

A measuring device and combined technology, which is applied in the direction of measuring device, testing material strength by applying stable shear force, testing material strength by applying stable tension/compression, etc., can solve single test items and rock and soil original state indicators The evaluation is one-sided and the shear strength of rock mass cannot be obtained, etc., so as to achieve the effect of simple operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

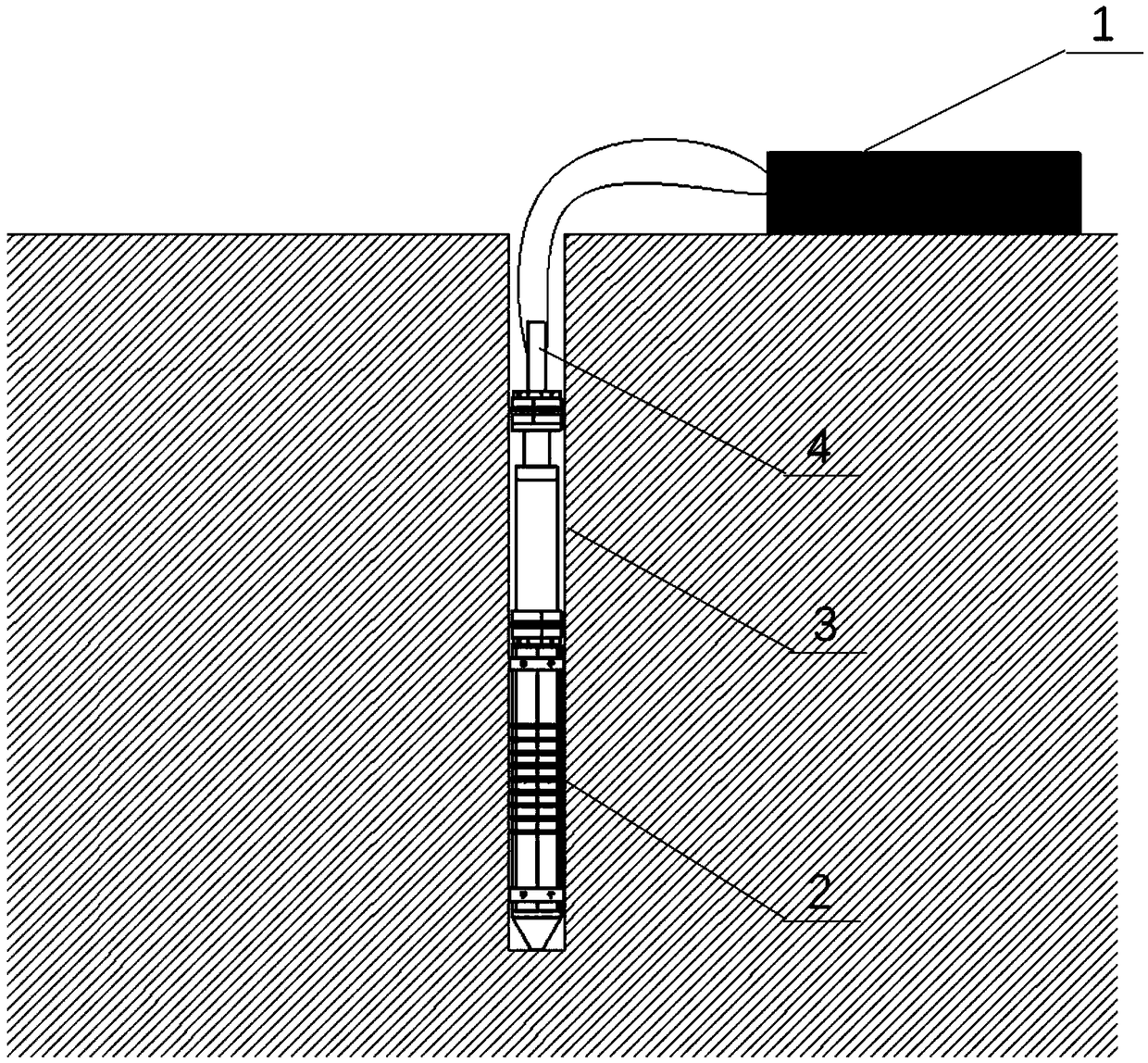

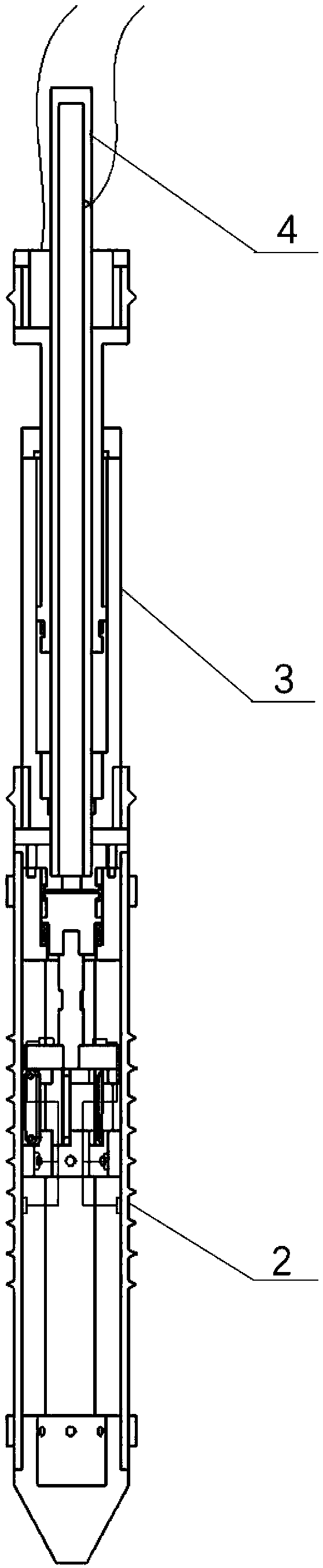

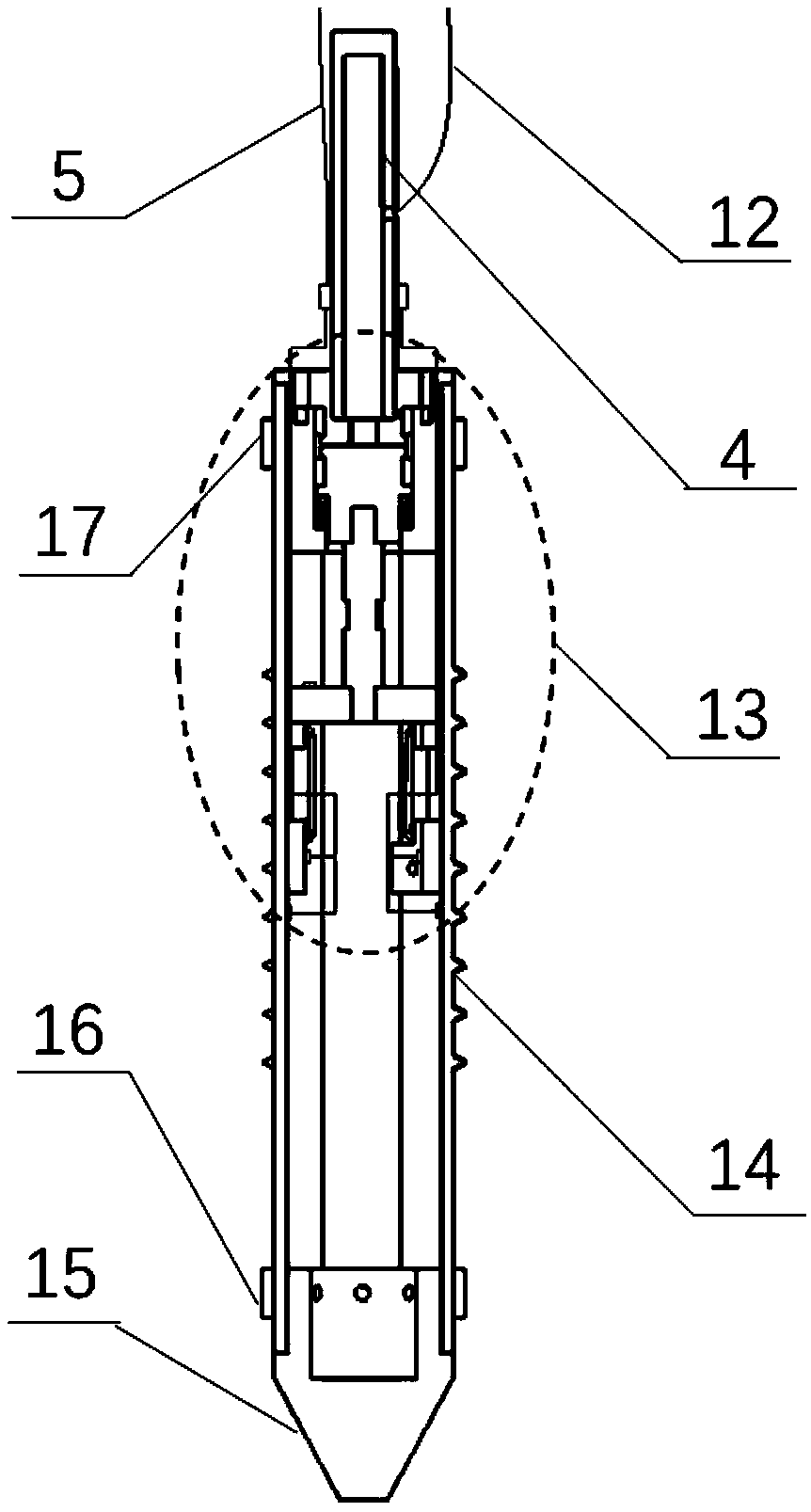

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention, below in conjunction with the accompanying drawings and specific implementation The method will describe the present invention in detail. see Figure 1 to Figure 5, shows the pre-drilled in-situ rock mass combined measurement device of the present invention.

[0034] The pre-drilled in-situ rock mass combined measurement device includes an auxiliary device 1, a shear measurement device 2, a compression measurement device 3 and an adapter 4, and the shear measurement device 2 is lowered to the bottom of the hole for the in-situ rock mass The deformation modulus and shear strength are measured, and the compression measuring device 3 is lowered to the bottom of the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com