Detecting method for detecting station for edging defect on back layer of rear view mirror

A technology for detection stations and detection methods, applied in the field of intelligent detection, can solve the problems of large limitations of manual detection methods, difficult detection of weak defects, dust and electrostatic influence, etc., to ensure inspection accuracy, avoid secondary pollution, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

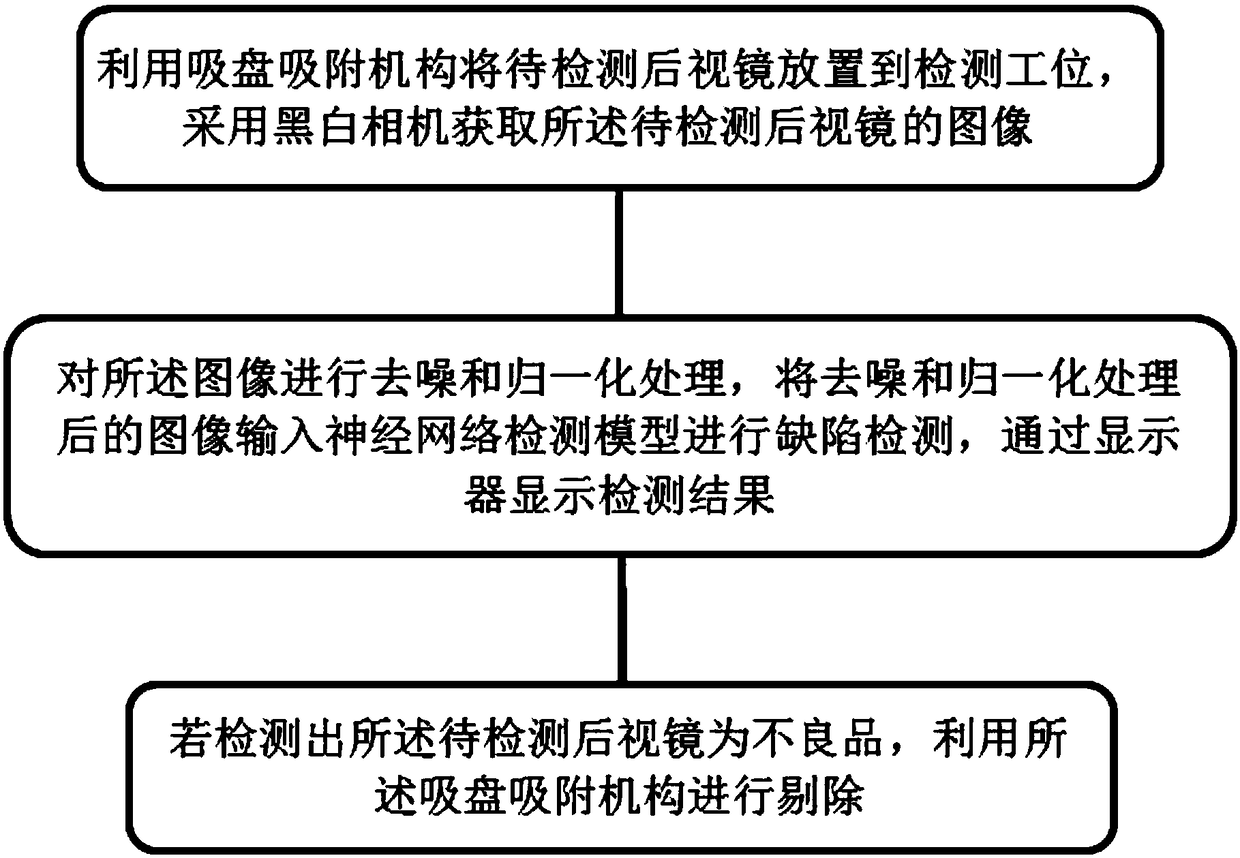

[0026] See attached figure 1 , the present invention provides a kind of detection method that is used for rearview mirror backside layer edging defect detection station, comprises the following steps:

[0027] Step 1, using the suction cup adsorption mechanism 1 to place the rearview mirror 4 to be detected on the detection station 2, and using a black and white camera to obtain the image of the rearview mirror to be detected;

[0028] The rearview mirror 4 to be detected is transported by a transmission mechanism 3 that adopts a double-layer conveyor belt. One conveyor belt is used to transmit the rearview mirror 4 to be detected, and the other conveyor belt is used to transmit defective product rearview mirrors. The suction cup adsorption mechanism 1 is arranged on the transmission Mechanism 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com