A NdFeB magnet auxiliary processing device and processing method thereof

An auxiliary processing and NdFeB technology, which is applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of NdFeB magnet collision, affecting the quality of NdFeB magnets, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

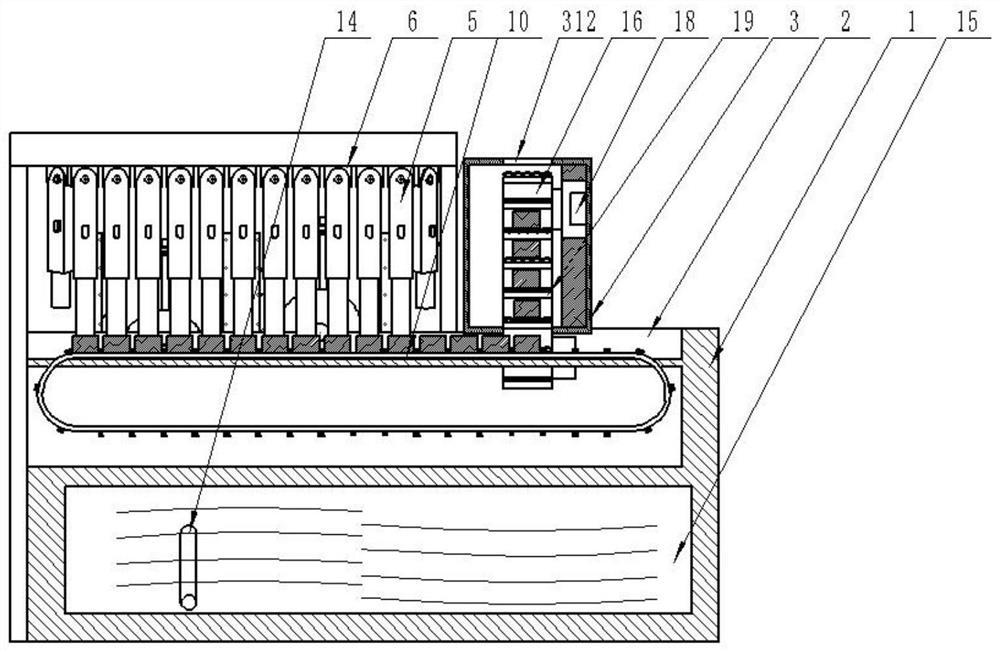

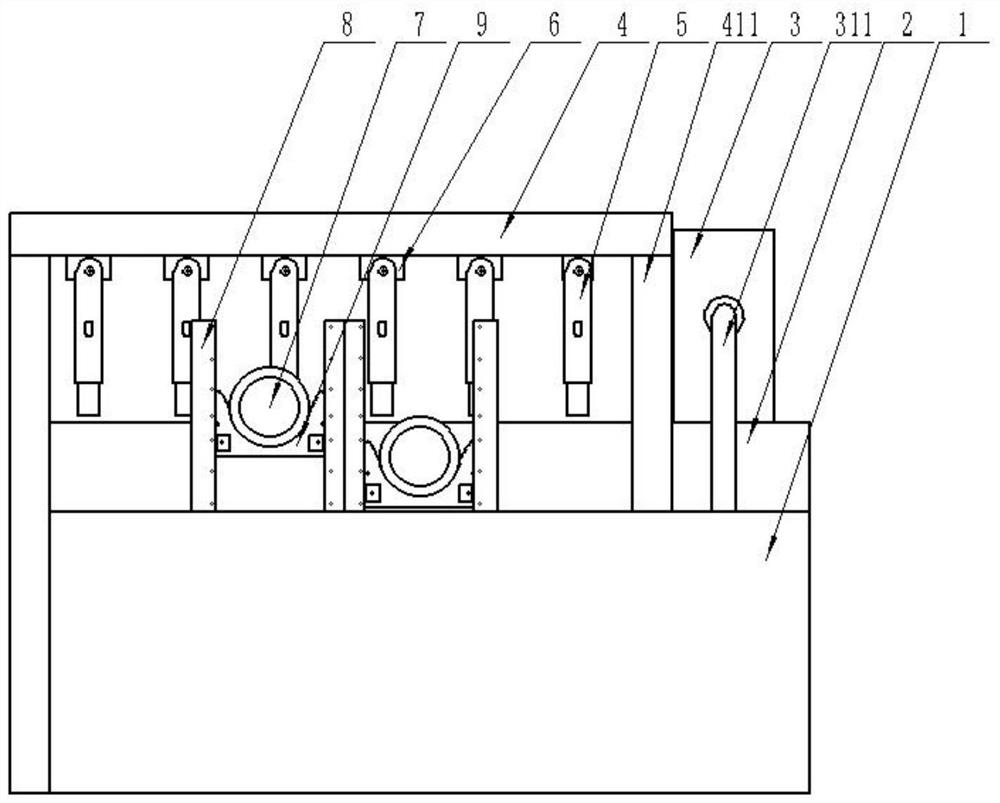

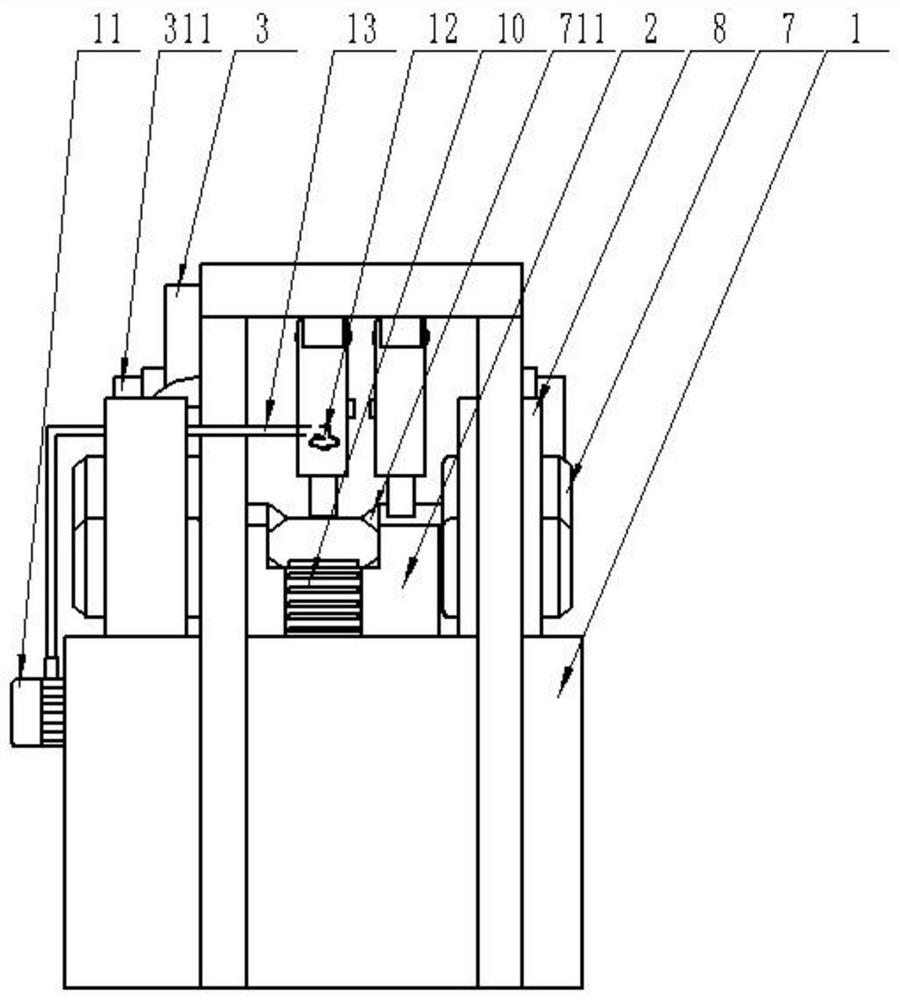

[0101] Such as Figure 1-7 As shown, a NdFeB magnet auxiliary processing device, a base 1, a workbench 2 is arranged on the base 1, two groups of relative processing motors 7 are arranged at the left end of the workbench 2; a feeding device 3 is arranged at the right end of the workbench 2 , the feeding device 3 is provided with a fixed rod 311 connected to the base 1; the left and right ends of the feeding device 3 are provided with a blanking unit 16, and the blanking unit 16 is provided with several stabilizing plates 19; An elevating device 9 is provided, and auxiliary elevating devices 8 are provided on both sides of the elevating device 9 for adjusting the height of the grinding head 711 so as to adjust the chamfering or rounding of the NdFeB magnets processed by the grinding head 711. And a transporting device 10 is arranged in the middle of the workbench 2 .

[0102] The base 1 is also provided with a support column 411, and the support column 411 is correspondingly p...

Embodiment 2

[0121] Such as Figure 9 , 10 , Shown in 11 and 12, a kind of NdFeB magnet auxiliary processing device also includes on the basis of embodiment one:

[0122] The buffer unit 17 is evenly arranged above the stabilizing plate 19; the stabilizing plate 19 is provided with a buffer groove 1911, and the buffer groove 1911 is provided with a buffer apex 1912; Both the cushioning member 1716 and the second cushioning member are made of elastic material, and the elastic material can well increase the elastic force, thereby increasing the cushioning effect.

[0123] Buffer one 1712 top surface includes 1711 and bottom surface 1713, and the external shape of top surface 1711 and bottom surface 1713 are both convex or dome-shaped, this setting is used to further better buffer the NdFeB magnet during the feeding process , so as to further reduce the collision between NdFeB magnets.

[0124] The second buffer piece 1716 is located inside the buffer groove 1911. The second buffer piece 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com