A chain clamp type transmission mechanism and a chain clamp type transmission device for wet separation membrane extraction of a lithium ion battery

A lithium-ion battery and transmission mechanism technology, which is applied to secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as wear, scratches, contamination of diaphragms, etc., and achieves simple overall structure, convenient production, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 refers to Figures 1 to 3 as shown,

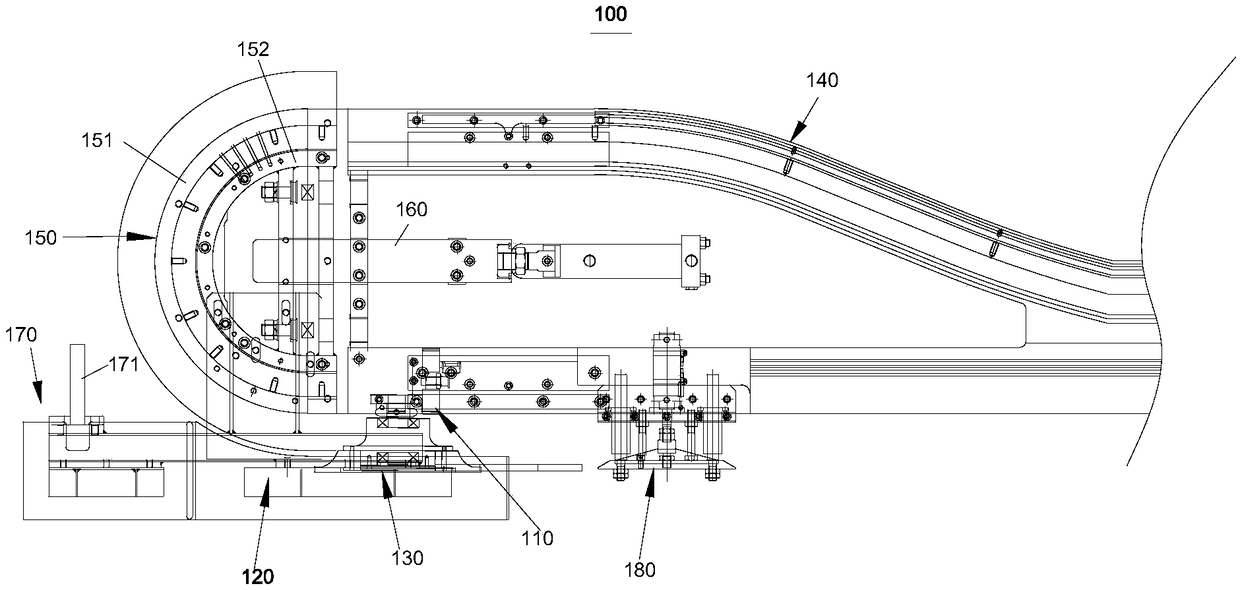

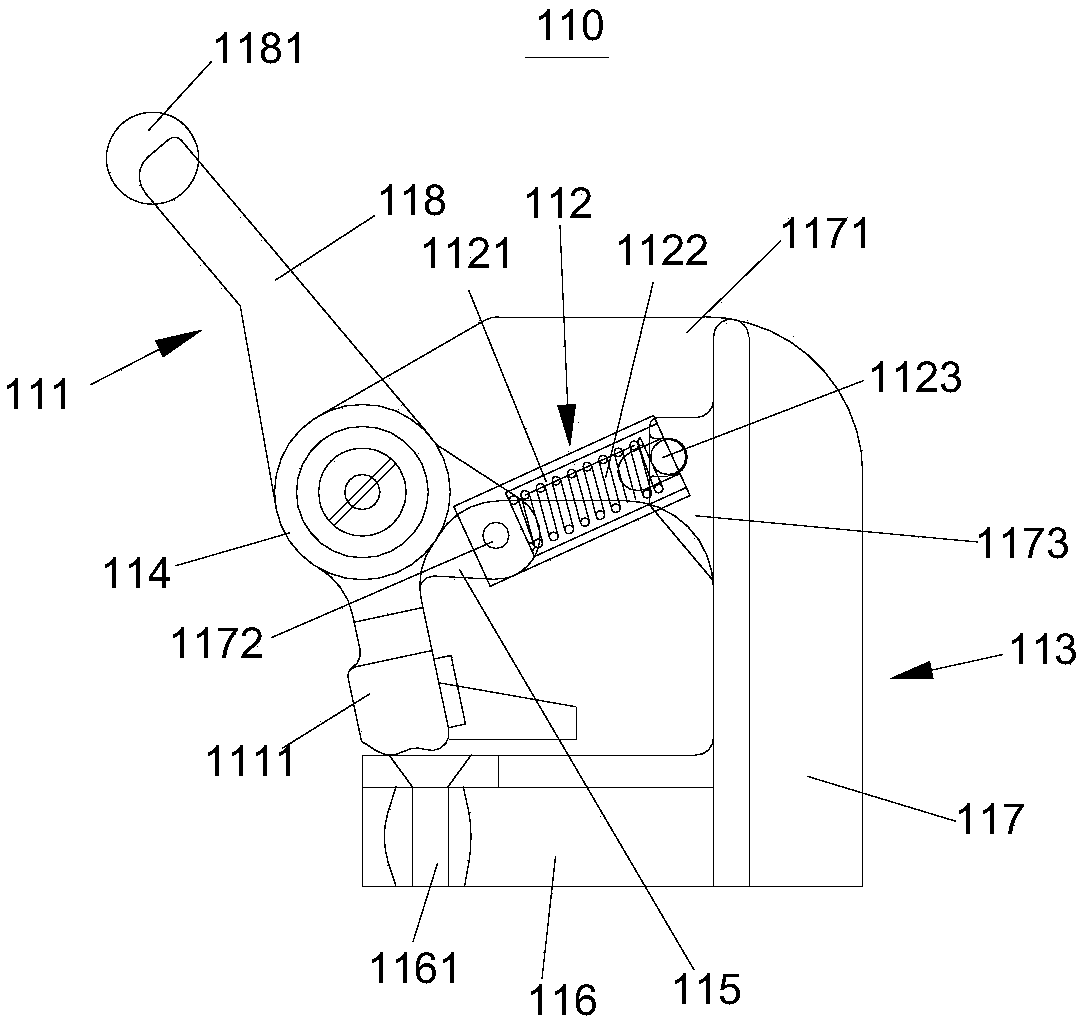

[0033] refer to figure 1 , the present invention provides a chain clip type transmission mechanism 100 for lithium ion battery wet diaphragm extraction, the chain clip type transmission mechanism 100 includes a chain clip body 110, a clip opener 120, a clip closer 130, a transmission chain 140, and a track plate 150 , power unit 160, guide roller 170 and second clamp closer 180.

[0034] refer to figure 1 , the transmission chain 140 is sleeved on the track plate 150, and the track plate 150 is fixedly connected with the power unit 160; the chain clip body 110 is in contact with the transmission chain 140, and the clip opener 120 and the clip closer 130 are arranged on opposite sides of the chain clip body 110 ; The guide roller 170 is fixedly connected with the clip opener 120 .

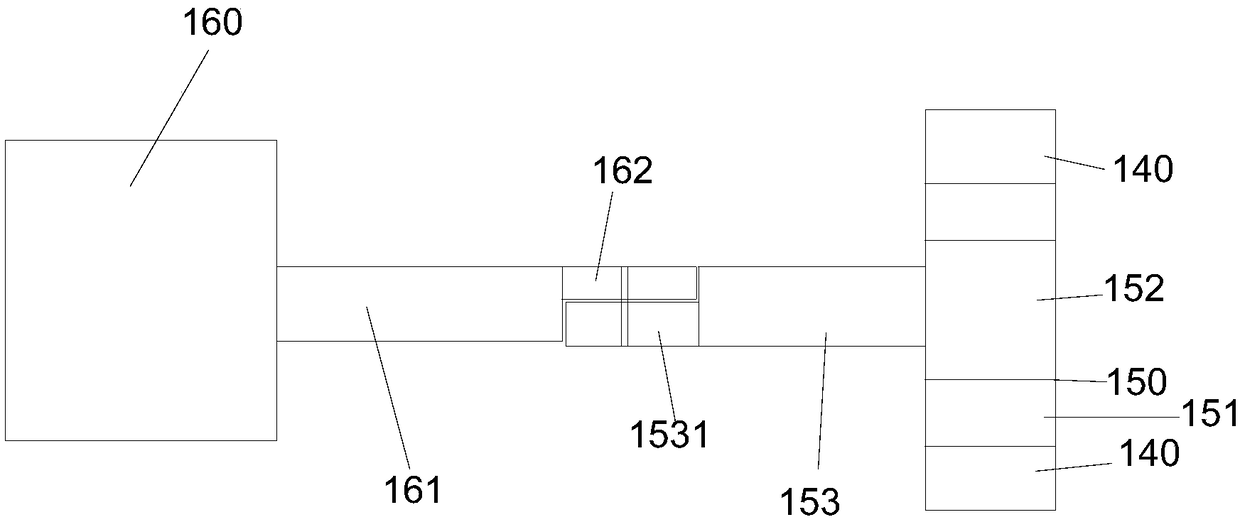

[0035] refer to image 3 , the track plate 150 includes a chain clip set 151 and a sprocket wheel 152, the chain clip set 151 is engage...

Embodiment 2

[0049] Embodiment 2 sees 4 to Image 6

[0050] The implementation principle and technical effect of the chain clamp type transmission mechanism 200 for lithium-ion battery wet diaphragm extraction provided by the embodiment of the present invention are the same as those of Embodiment 1. For a brief description, what is not mentioned in this embodiment can be Refer to the corresponding content in Example 1.

[0051] The chain clip type transmission mechanism 100 obtained by the design of embodiment 1 for wet diaphragm extraction of lithium-ion batteries can basically meet the daily use, but in order to further improve its function, the designer made a detailed analysis of the method for wet diaphragm extraction of lithium-ion batteries. The chain clamp transmission mechanism 100 has been further improved.

[0052] refer to Figure 4 , the present invention provides a chain clip type transmission mechanism 200 for lithium-ion battery wet diaphragm extraction. The chain clip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com