A brushless generator

A generator and housing technology, applied in the field of brushless generators, can solve the problems of reduced coolant utilization efficiency, short coolant residence time, incomplete heat exchange, etc., to achieve high utilization efficiency, good cooling effect, and flexibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

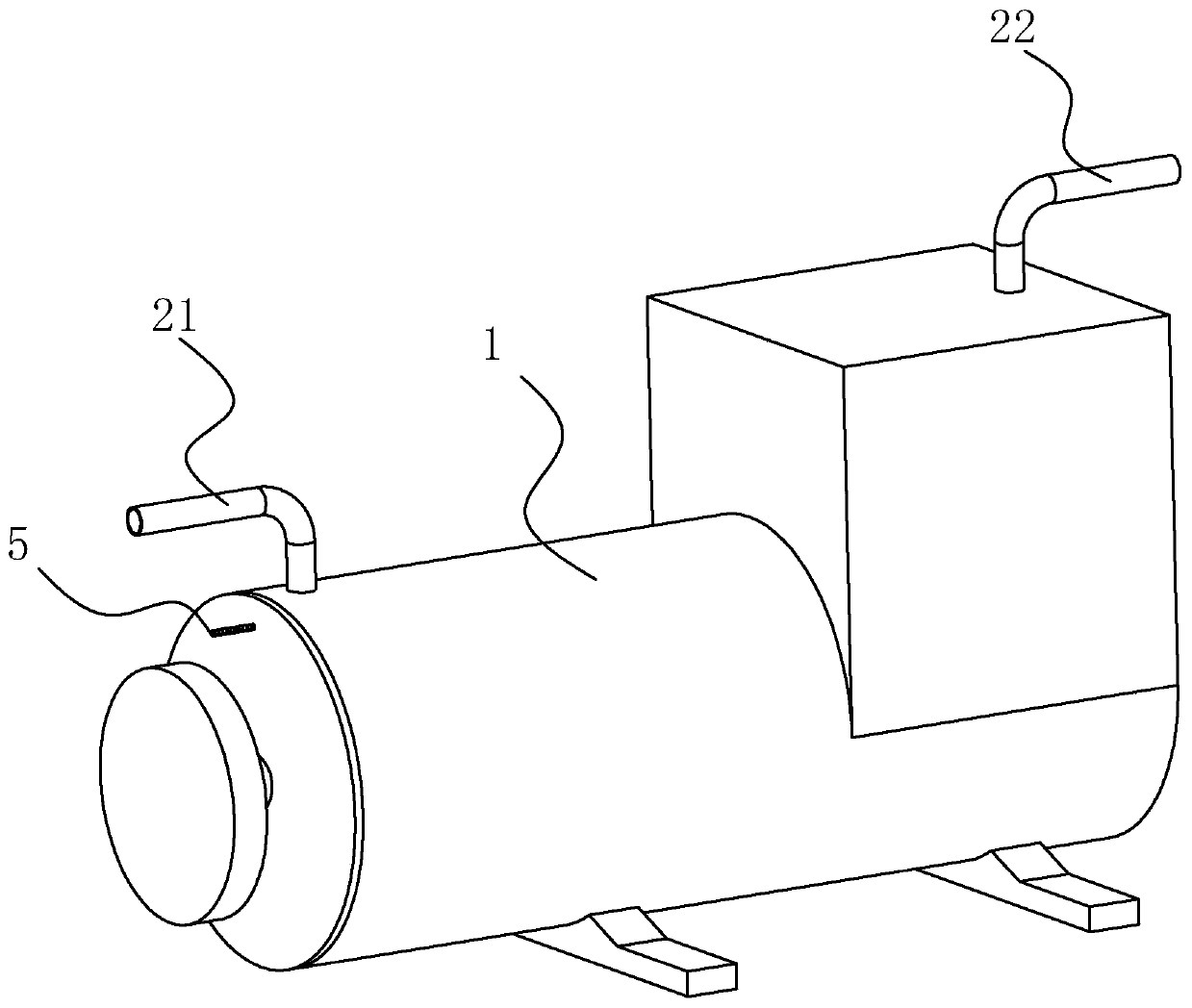

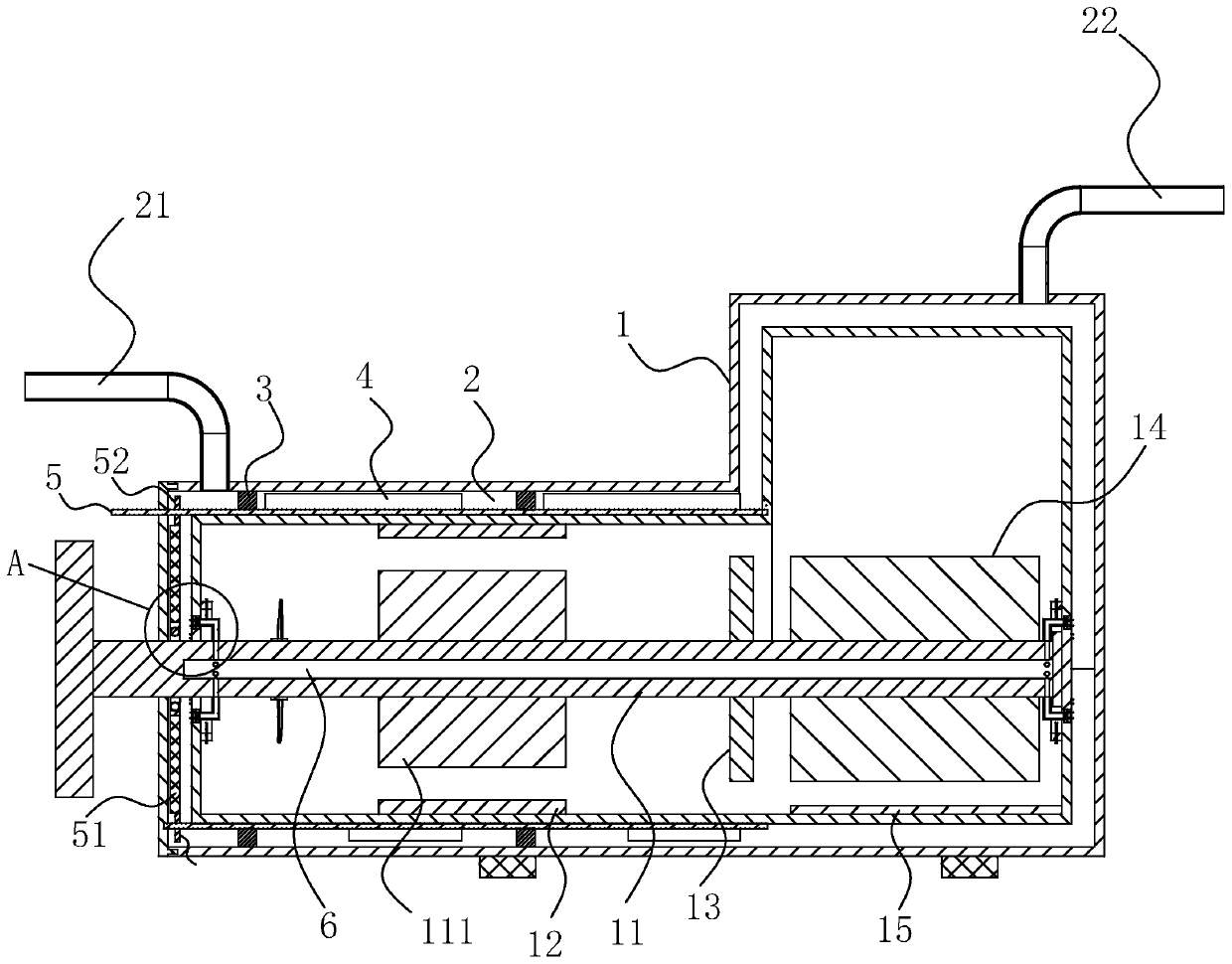

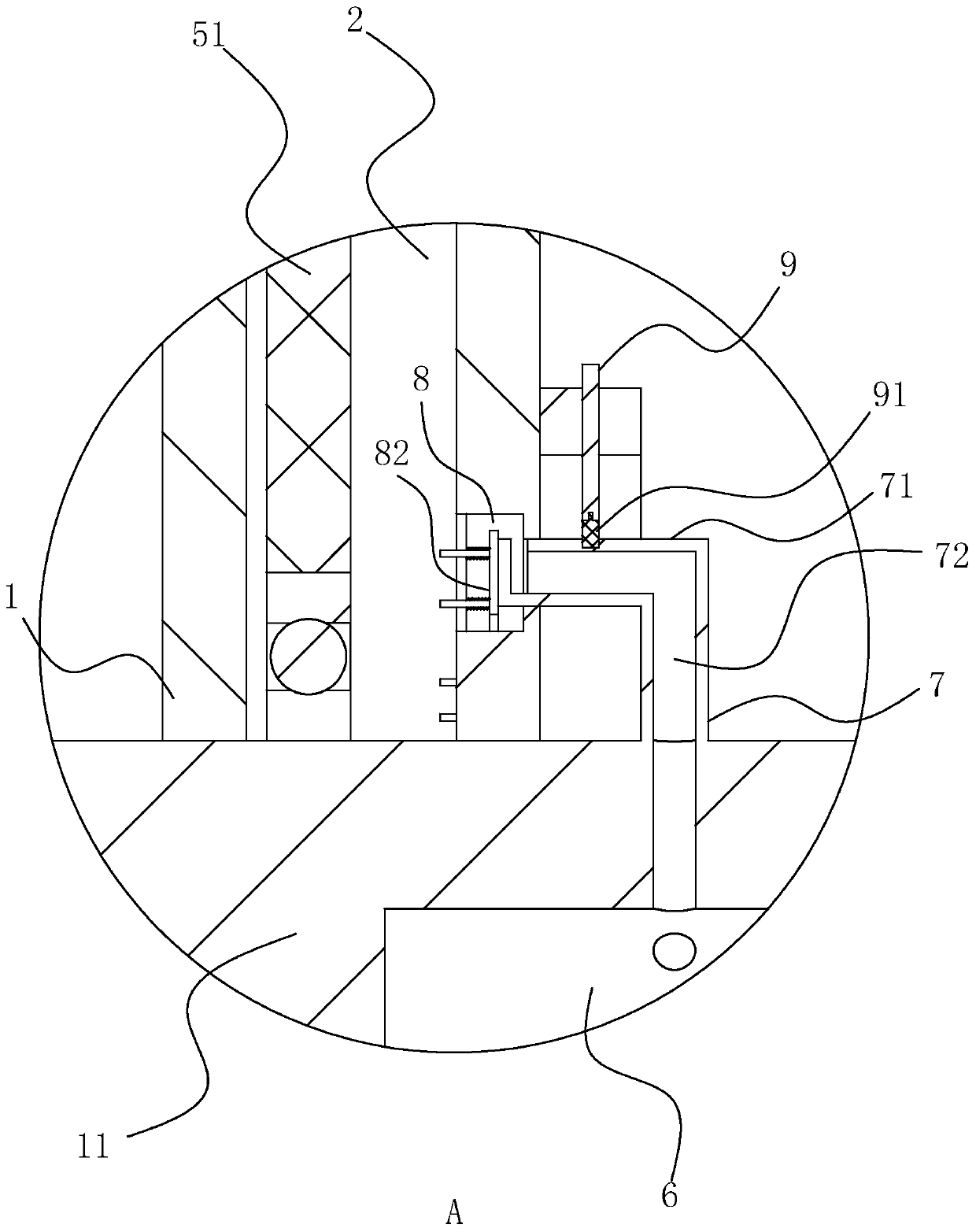

[0040] A kind of brushless generator, refer to figure 1 as well as figure 2, including a housing 1, a rotating shaft 11 is installed on the corresponding two sides of the inner wall of the housing 1, one side of the rotating shaft 11 passes through the brushless generator housing 1 and is connected to the flywheel connection plate, and a rotor 111 is installed on the rotating shaft 11, There are several first stators 12 around the rotor 111. The first stators 12 are installed on the inner wall of the brushless generator housing 1. A rotary rectifier 13 is installed on one side of the rotor 111. The rotary shaft 11 is located on the rotary rectifier. 13 An exciter 14 is installed on the side away from the first stator 12, and there are several second stators 15 around the exciter 14, and the second stator 15 is installed on the inner wall of the brushless ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com