Fruit picking control method

A control method and fruit technology, applied to picking machines, ladders, buildings, etc., can solve the problems of less picking machinery, labor-intensive work, danger, and large impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

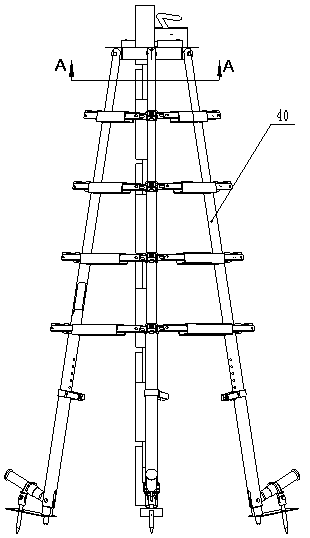

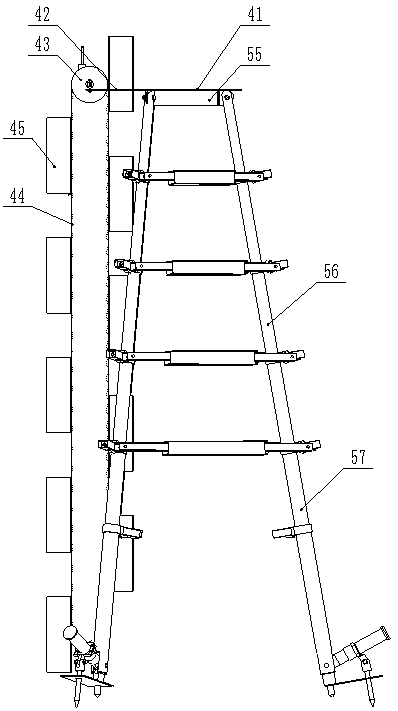

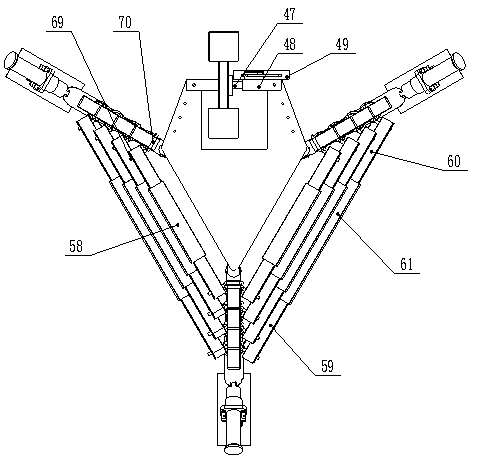

[0041] The present invention will be further described in detail below with reference to the accompanying drawings in the specific embodiments of a fruit picking ladder.

[0042] When implementing: as Figure 1 to Figure 12 As shown in the figure, a fruit picking control method is arranged vertically on one side of the picking ladder, and a container fixed on the driving belt drives the picked fruit to be transported downward by its own weight. It is characterized in that when the fruit is transported downward, the The foot presses a pressing member to control the contact friction pressure between the pressing member and the gear side of the transmission belt at the upper end of the transmission belt, thereby realizing the control of the downward falling speed of the container and its fruit, and realizing the smooth downward transmission of the fruit.

[0043] In this way, by stepping on the foot, the operator can be released, which has the advantage of more convenient operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com