Magnetic separator with self-cleaning function for feed processing

A feed processing and self-cleaning technology, applied in the field of magnetic separators, can solve the problems of short contact time between feed and permanent magnet blocks, accumulation of wastes in permanent magnet blocks, poor screening effect, etc., achieving a wide range of applications, convenient processing and simplified maintenance The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

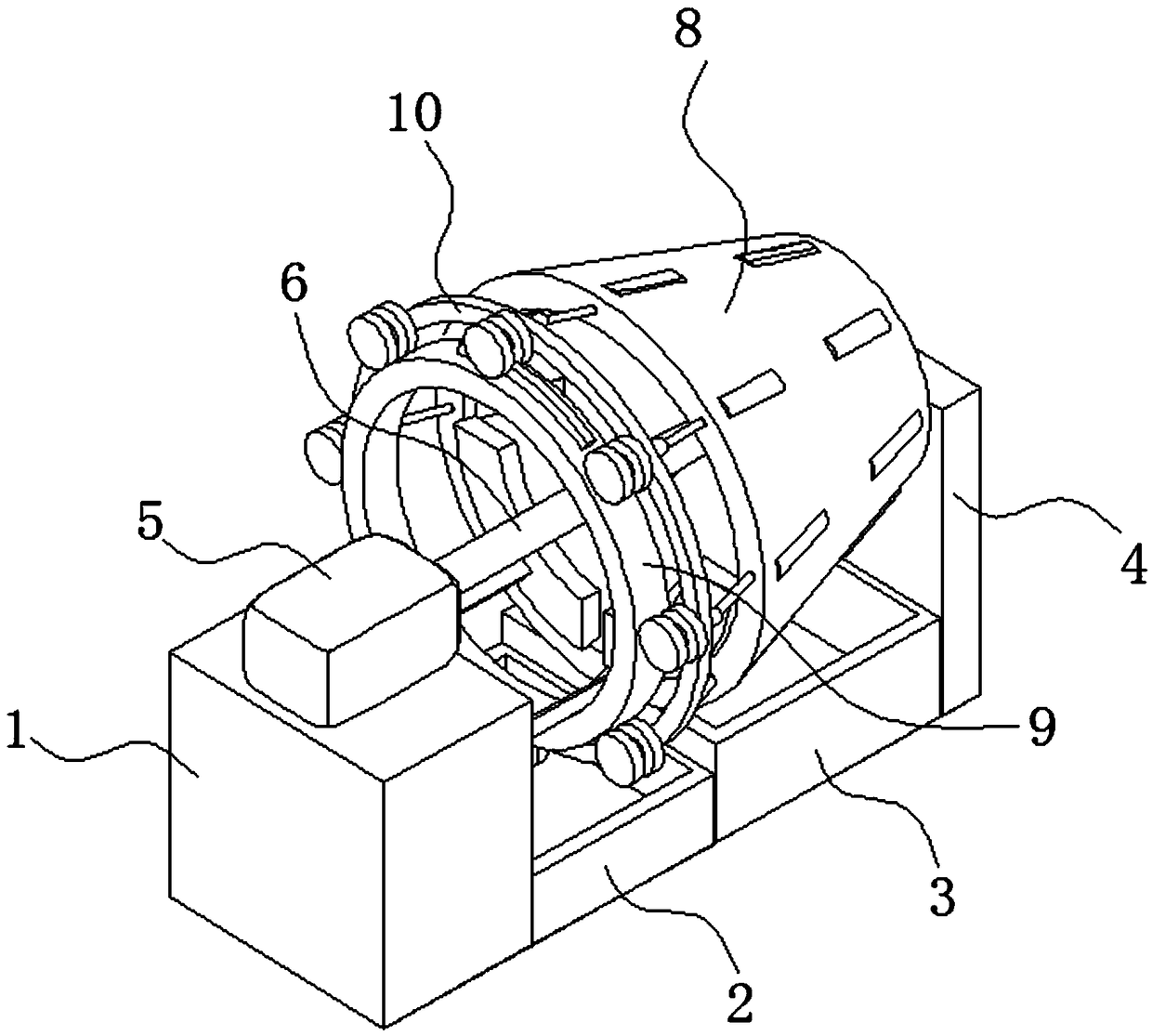

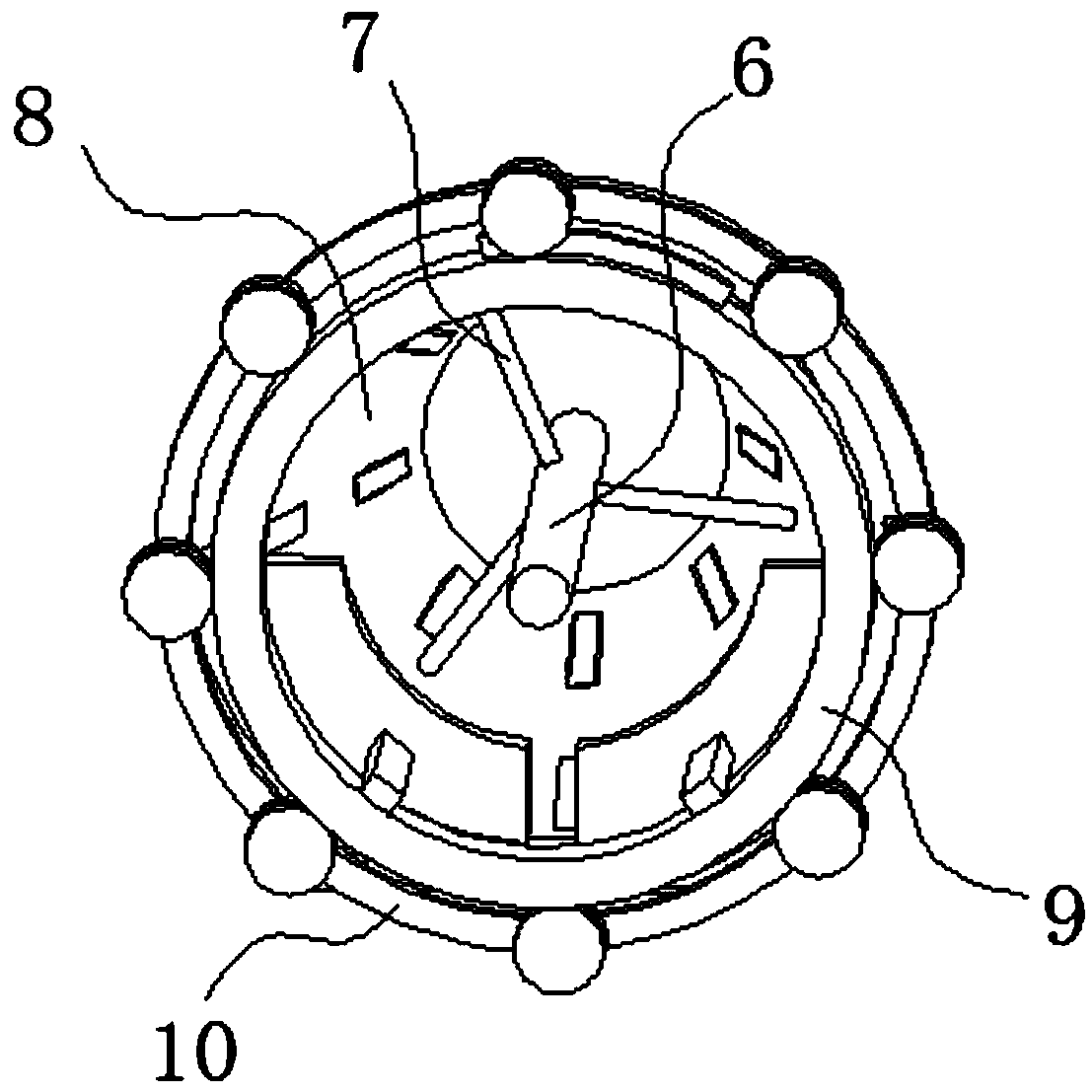

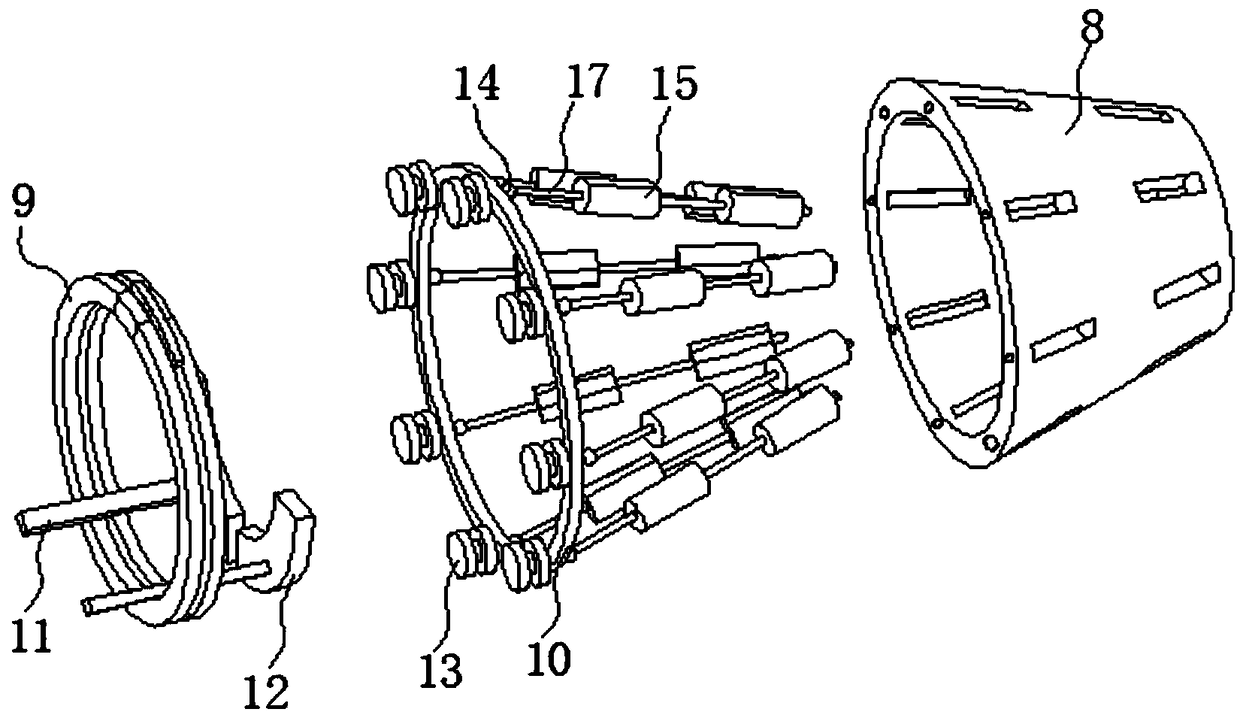

[0031] see Figure 1-9 As shown, the present embodiment provides a magnetic separator with self-cleaning function for feed processing, including a power supply box 1, a power supply for the electromagnetic board 1502 and the drive motor 5 is provided in the power supply box 1, and the power supply box 1 The lower end of the side wall of the feed collection box 2 is fixedly connected with a feed collection box 2 for collecting the feed that has been screened. The si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap