Low-order coal slurry flotation collecting agent compounded with ketone aldehyde ether and preparing method and application of low-order coal slurry flotation collecting agent

A coal slime flotation and collector technology, which is applied in flotation, solid separation and other directions, can solve the problems of increasing toxic and harmful components, easily harming the ecological environment, and complex wastewater components, so as to improve flotation efficiency and simplify flotation. process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

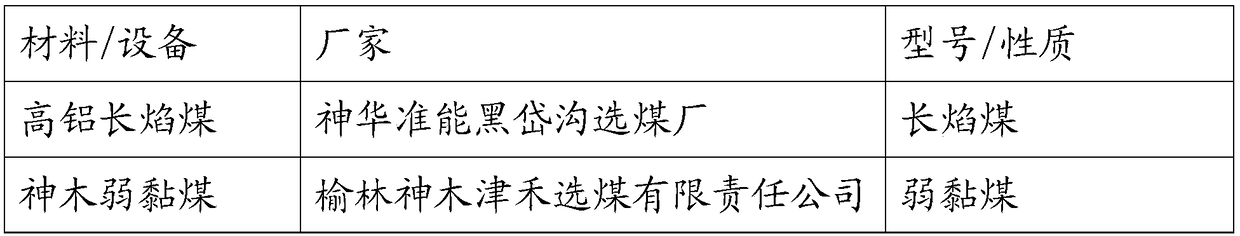

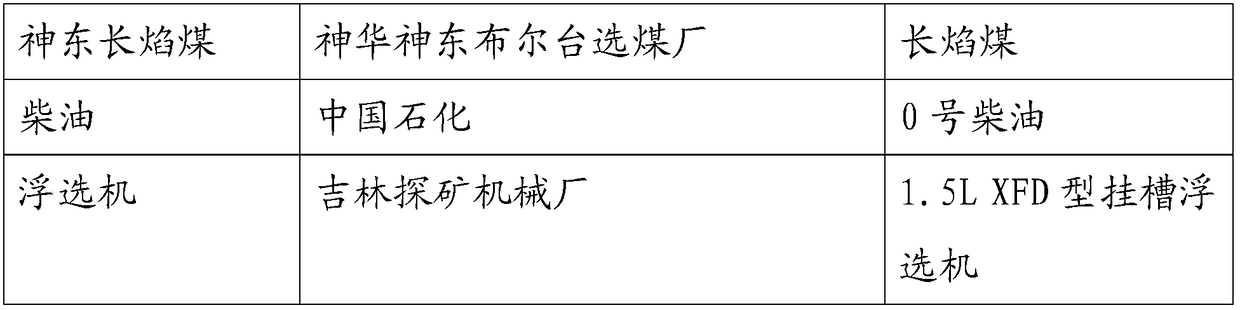

[0039] Coal slime properties: The coal sample comes from the high-aluminum long-flame coal of Shenhua Zhuneng Heidaigou Coal Preparation Plant, the inner ash of the coal slime is high, and the ash content of the incoming coal slime is 37%. The particle size of the coal sample is relatively fine, and the -0.074mm particle size coal slime accounts for 60% of the coal sample.

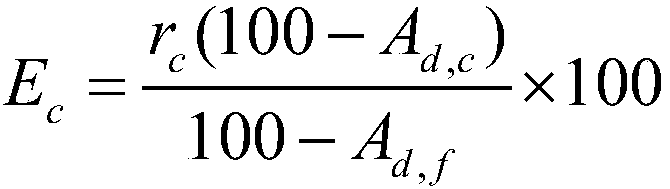

[0040] Operating conditions: 1.5L XFD type hanging cell flotation machine is used, and the spindle speed is 2000rpm. Weigh 120g of dry coal slime and pour it into a flotation tank filled with tap water to prepare a flotation pulp (pulp concentration 80g / L), add collector and stir for 3min, add foaming agent 2-octanol and stir for 30s, then pass in gas (inflated volume 0.25m 3 / h) after scraping and foaming for 3 minutes, the scraped foam and the residue at the bottom of the tank are flotation clean coal and flotation tailings, which are filtered, dried and weighed respectively, and the recovery rate of pr...

Embodiment 1-1

[0042] In Example 1-1, in terms of mass fraction, the ratio of the flotation collector is 70% of diesel oil, 12% of diisobutyl ketone, 8% of n-valeraldehyde, and 10% of n-pentyl ether. The preparation process is as follows: diesel oil, diisobutyl ketone, n-valeraldehyde and n-pentyl ether are mixed in proportion, and stirred at a speed of 1000 rpm for 15 minutes to obtain the flotation collector.

Embodiment 1-2

[0044] Example 1-2 is similar to Example 1-1, the only difference is that the collector ratio is: 60% of diesel oil, 15% of diisobutyl ketone, 10% of n-valeraldehyde, and 15% of n-amyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com