Pneumatic control constant pressure self-adaptive polishing grinding head

A constant pressure and air pressure control technology, applied in optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of unstable polishing pressure and uneven pressure distribution, and achieve constant pressure, stable removal function, and improved control. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the protection scope of the present invention.

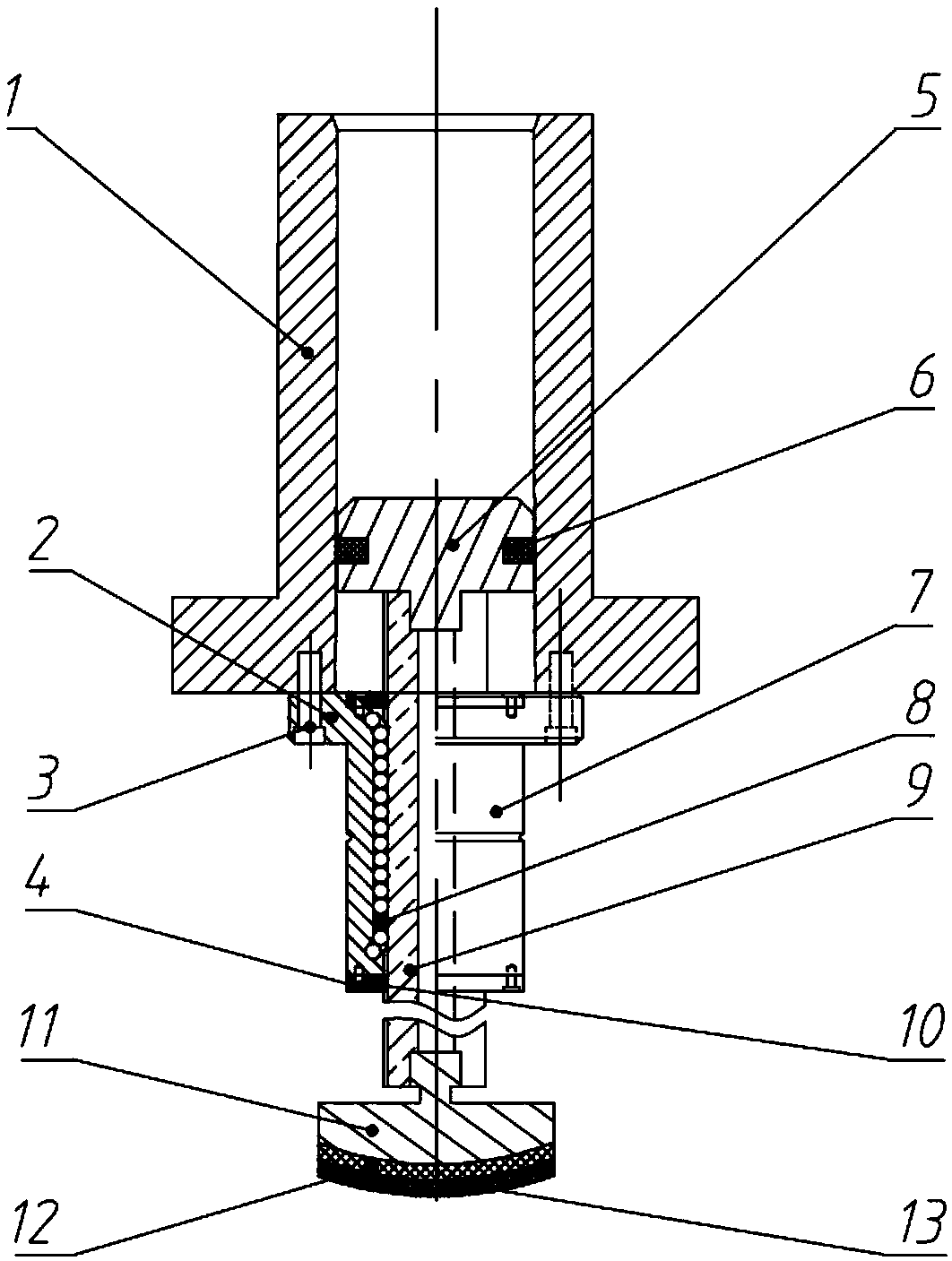

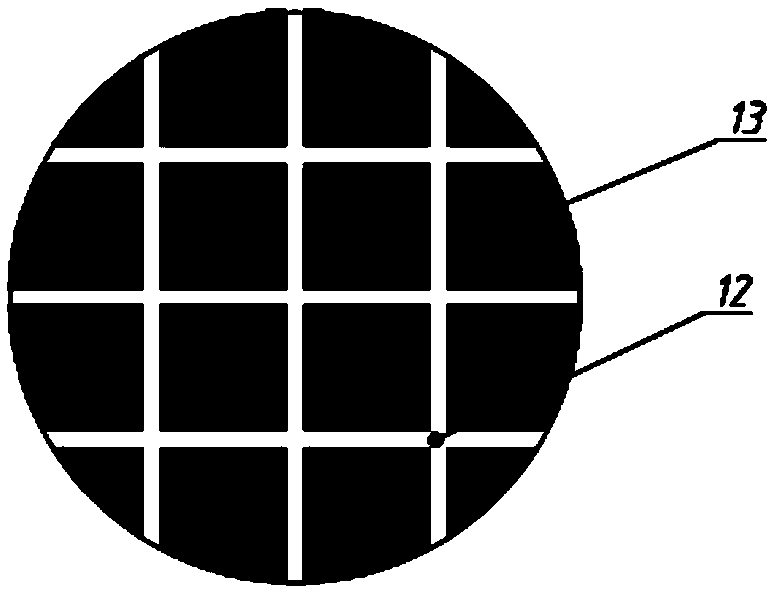

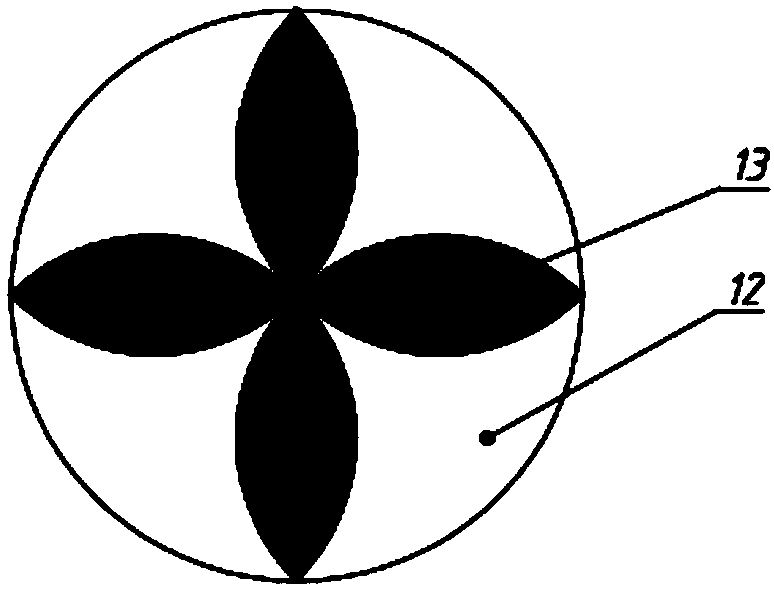

[0023] See attached figure 1 , an air pressure control constant pressure self-adaptive polishing grinding head of the present invention, comprising a main shaft sleeve 1, a connecting flange 2, a fastening screw 3, a set screw 4, a piston 5, a sealing ring 6, a linear bearing 7, a roller 8. Tool spindle 9, limit flange 10, disc base 11, flexible layer 12, polishing layer 13.

[0024] The main shaft sleeve 1, the connecting flange 2, the linear bearing 7, and the limit flange 10 are coaxial and are fixedly connected and assembled concentrically by the fastening screw 3 and the fastening screw 4 to form a through hole. The tool main shaft 9, the piston 5 Through the coaxial and tight connection of the hole shaft interference fit, and through the slot matched with the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com