Usage method of two-stage vacuum extruder

A vacuum extruder, two-stage technology, used in ceramic molding machines, ceramic extrusion dies, manufacturing tools, etc., can solve problems such as uneven water mixing, mud splashing, etc., to improve production quality, stable power transmission, and product quality. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

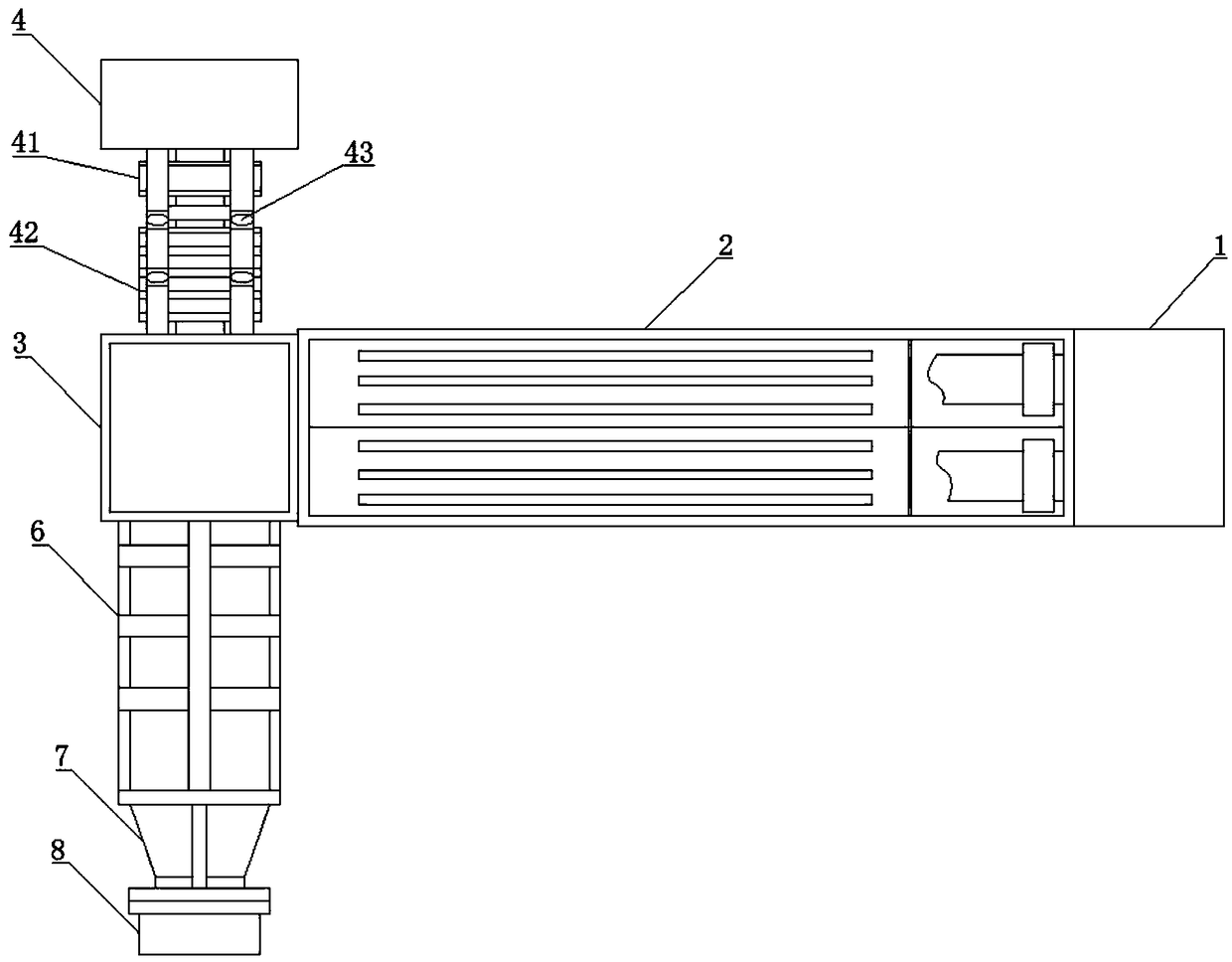

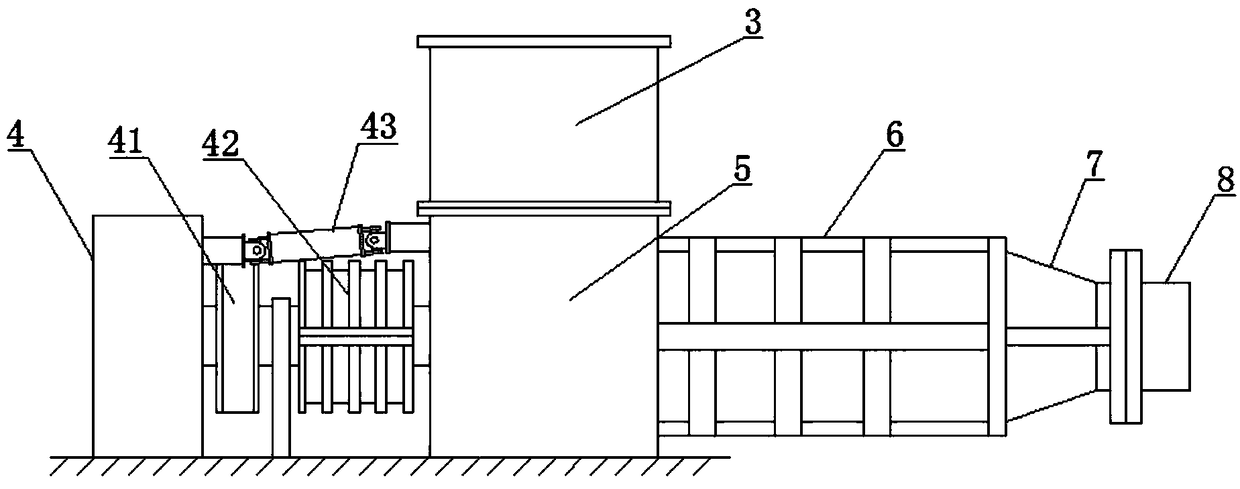

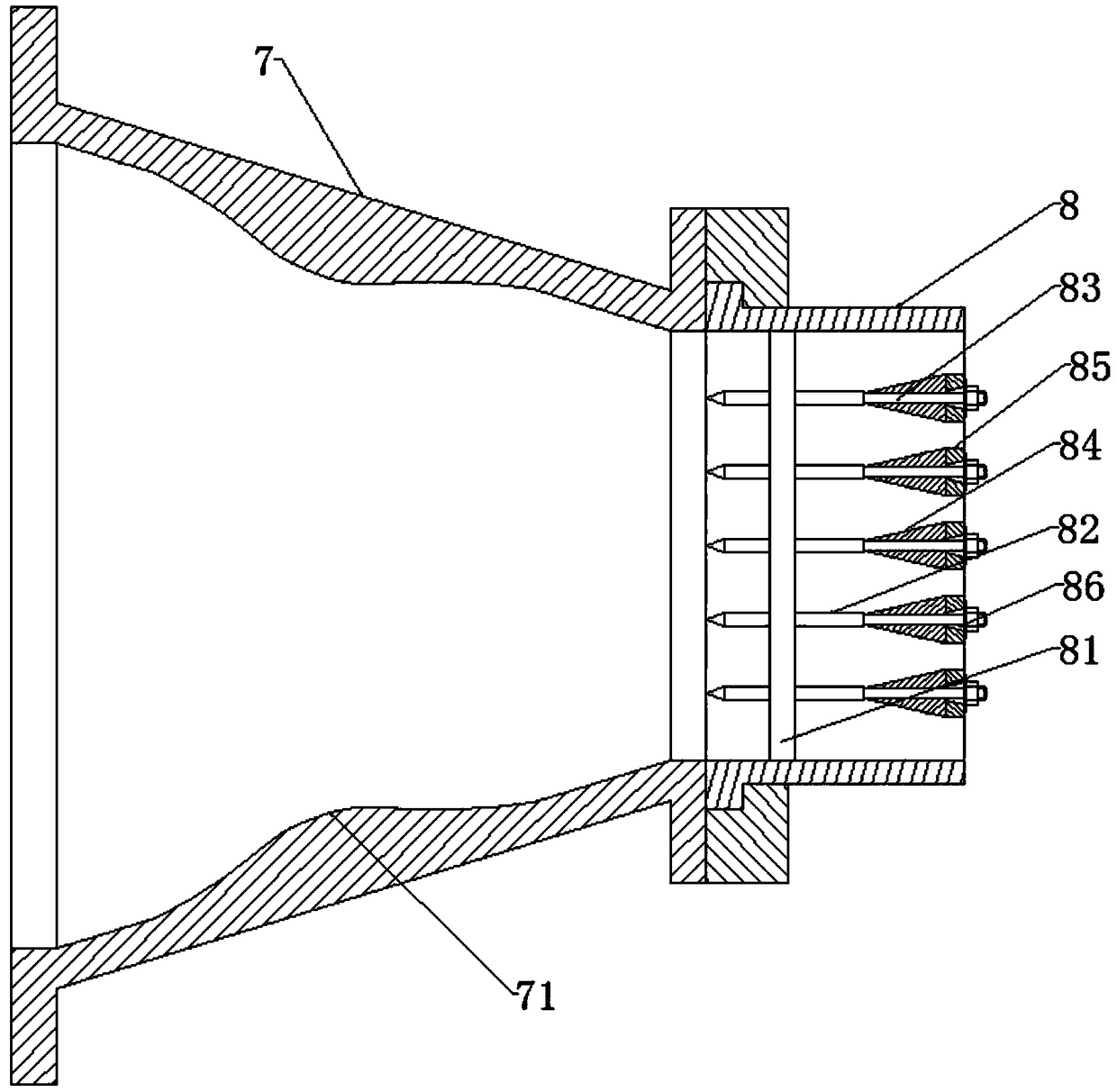

[0019] Embodiment: This embodiment provides a kind of two-stage vacuum extruder, as figure 1 , figure 2 As shown, it includes an upper-level device and a lower-level device. The upper-level device includes an upper-level reducer 1, a feed box 2, and a vacuum box 3 connected in sequence from right to left. The inner bottom section of the feed box 2 has two intersecting circles. Arc, two side-by-side spiral reamer shafts are pierced in the feed box 2, and a partition plate is arranged in the feed box 2, and the partition plate separates the feed box 2 into a feed chamber and a transfer chamber, and the feed box The top opening of 2 is set, and the upper reducer 1 and the two spiral reamer shafts are connected by a coupling. The inner wall of the top opening of the feed box 2 is equipped with a single row of atomizing nozzles. The spray end is towards the inside of the feed box 2 . The upper and lower ends of the vacuum box 3 are all opened, and the upper opening of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com