A rotating device for helicopter fuselage assembly

A technology for rotating devices and helicopters, applied in aircraft assembly, etc., can solve problems such as difficult positioning, difficult rotation adjustment, etc., achieve automatic assembly, improve assembly speed and assembly quality, and have good openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

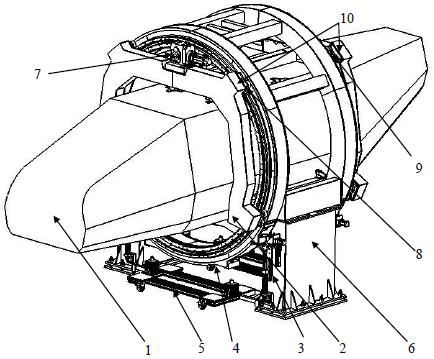

[0037] Such as figure 1 As shown, a rotating device for helicopter fuselage assembly of the present invention includes: helicopter 1, rotating bracket 2, hydraulic positioning mechanism 3, lower assembly 4, trolley 5, main body 6, driving assembly 7, roller 8, V-shaped Roller 9, roller seat 10. The implementation process is described in detail below.

[0038] Such as Figure 7 , Figure 8 As shown, the main body 6 includes an annular main body 63 and a base 65, the annular main body 63 is placed on the base 65, and the front and rear ends of the annular main body 63 are provided with upper circular arc guide rails and upper circular arc ring gears; The upper arc guide rail includes an upper arc guide rail 61 at the front end and an upper arc guide rail 66 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com