Solid solution treatment device for U-shaped heat exchange tubes

A technology of solid solution treatment and heat exchange tubes, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as potential safety hazards of conductors, safety accidents, inconsistent distance between positioning points, etc., and achieve the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

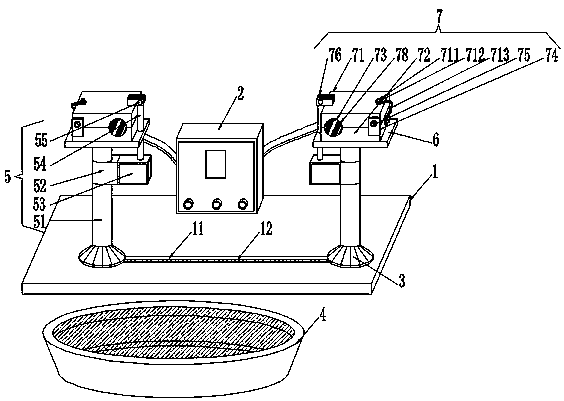

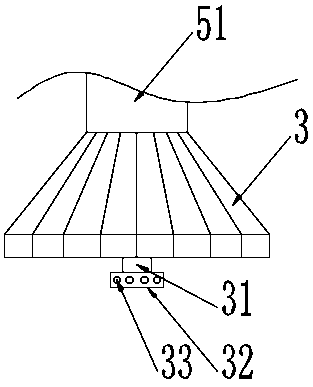

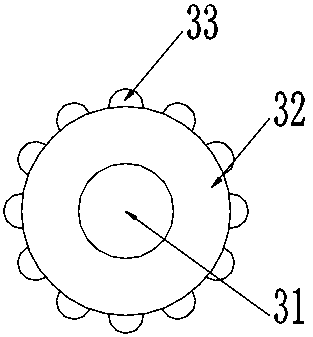

[0031] A U-shaped heat exchange tube solid solution treatment device, comprising a base 1, a power supply box 2, a sliding seat 3, a cooling pool 4, a pneumatic opening and closing mechanism 5, a carrier plate 6 and a clamping heating mechanism 7, and the upper end surface of the base 1. A power supply box 2 is fixedly installed near the center of one side, and two sliding seats 3 are slidably installed on the base 1. The specifications of the two sliding seats 3 are the same and the connecting line between each other is parallel to the power box 2, and the base 1 One side is provided with a cooling pool 4, the tops of the two sliding seats 3 are fixedly installed with a pneumatic opening and closing mechanism 5, the tops of the two pneumatic opening and closing mechanisms 5 are fixedly installed with a carrier plate 6, and the upper ends of the two carrier plates 6 are fixed A clamping heating mechanism 7 is installed. The two clamping heating mechanisms 7 have the same specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com