Automated detection method and device for face difference and gap of automobile large sheet metal parts

A technology for automatic detection and sheet metal parts, which is applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of large man-hours, labor, and low accuracy, and improve accuracy, data, etc. Acquisition fast, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

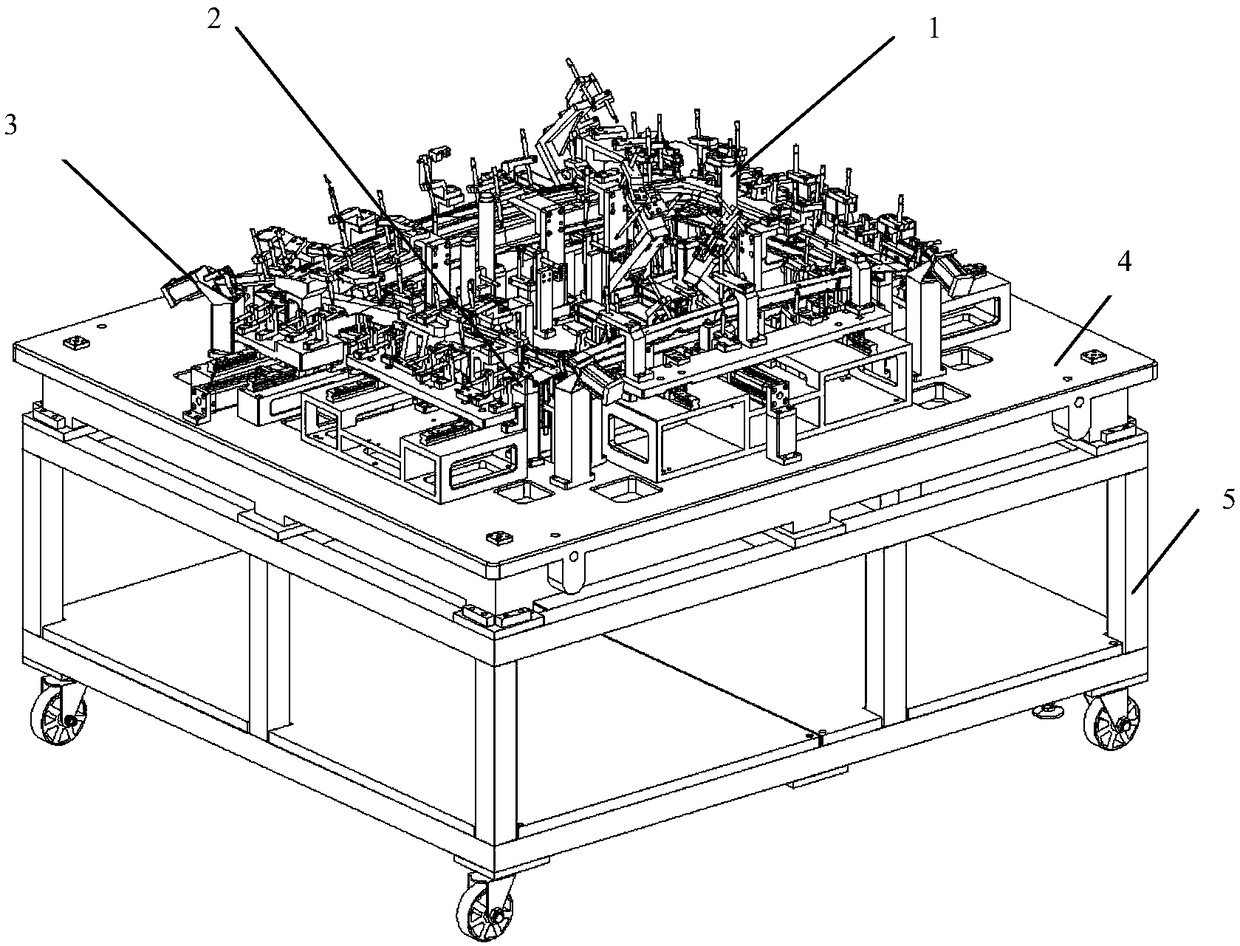

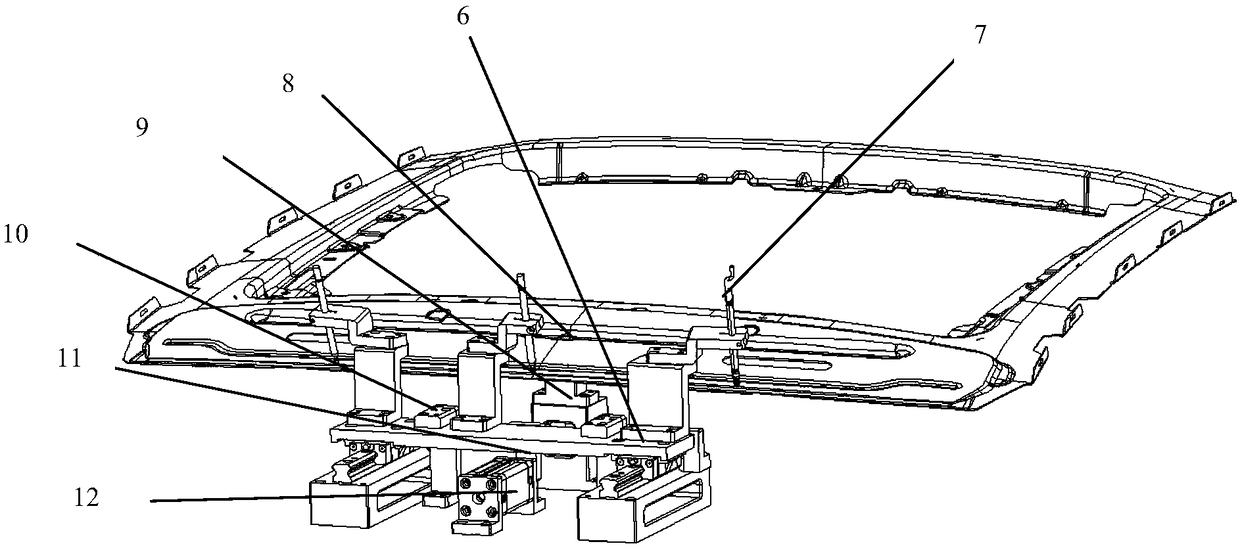

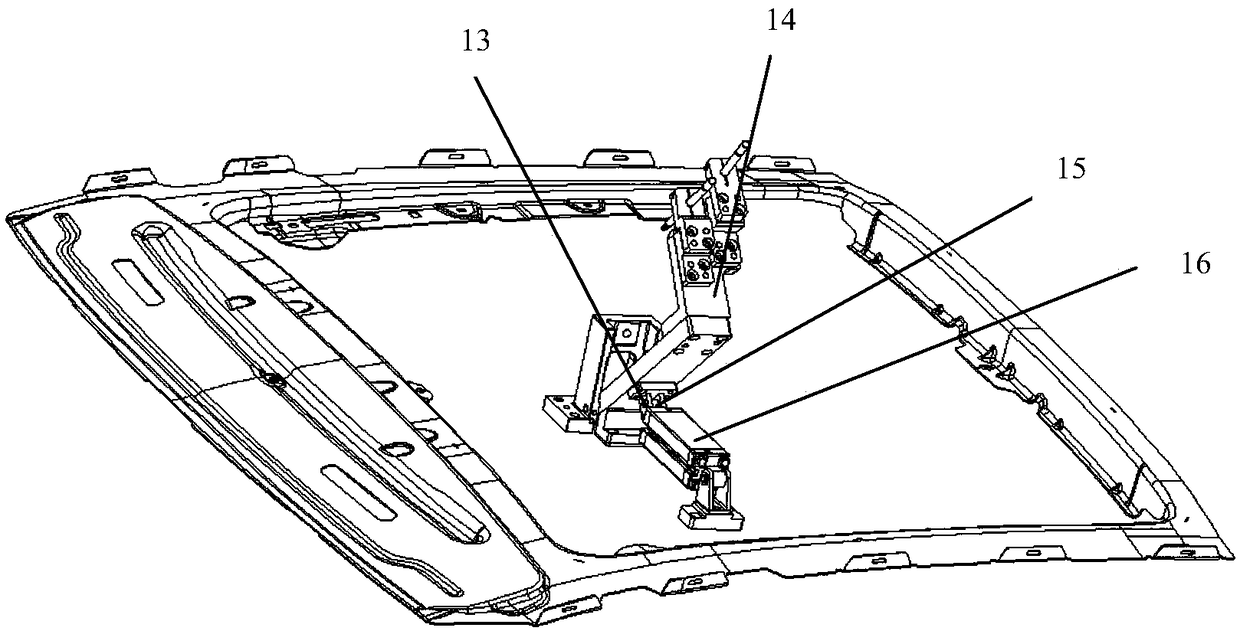

[0042] Such as figure 1 The shown schematic diagram of the structure of the device of the present invention includes a cylindrical PVC initial positioning, a translation detection movement module, a rotation detection movement module, a contact displacement sensor, a power pressing mechanism, a positioning support mechanism, a position judgment electromagnetic switch, a base plate, Measurement control module and data processing module.

[0043] Among them, the initial positioning of the cylindrical PVC is located on the bottom plate, and is fixedly connected with the bottom plate, which is used for the initial positioning of the product installation and assists in the rapid installation of the product. figure 1 In the embodiment, it is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com