A kind of preparation method of high-concentration graphene oxide dispersion liquid

A technology of dispersion liquid and fossil is applied in the field of preparation of high-concentration graphene oxide dispersion liquid, which can solve the problems such as restricting the research on the properties and applications of graphene oxide, unfavorable large-scale purification of graphene oxide, unstable graphene oxide structure, etc. , to achieve the effect of convenient washing process, excellent stability, and low toxicity of purification reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, preparation graphene oxide dispersion liquid

[0033] (1) First, apply the Hummers method to oxidize graphite to obtain graphite oxide. The obtained graphite oxide was pre-purified with aqueous hydrochloric acid (the volume ratio of hydrochloric acid to water was 1:10). Then soak the graphite oxide in absolute ethanol for about 4 hours, then centrifuge to remove the ethanol supernatant, soak the precipitate in absolute ethanol again, and repeat this process 3-5 times. Finally, centrifuge to obtain ethanol-purified graphite oxide.

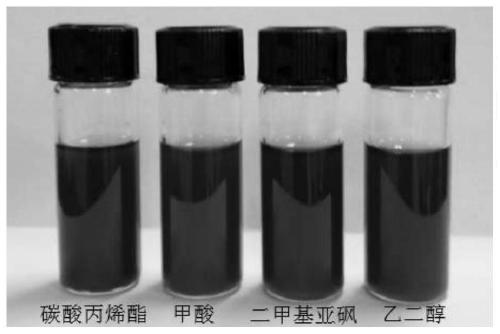

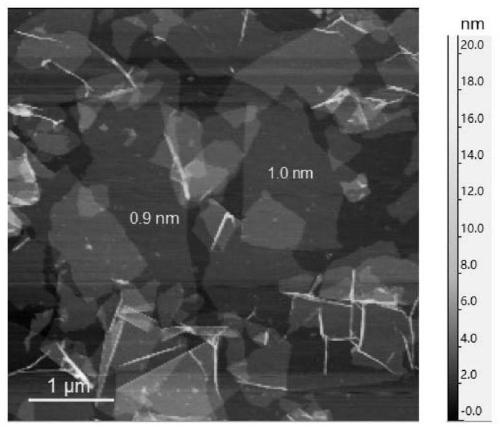

[0034] (2) Dry the graphite oxide purified by ethanol in the air for about 3 hours, then add an organic solvent (propylene carbonate, formic acid, dimethyl sulfoxide or ethylene glycol respectively) and mechanically stir for 15 minutes or gently sonicate (100W) After 10 minutes, an organic solvent dispersion solution of graphene oxide is obtained, wherein the concentration of graphene oxide is 10-40 mg / mL. Pictures of the pre...

Embodiment 2

[0037] Embodiment 2, preparation graphene oxide dispersion liquid

[0038] (1) First, apply the Hummers method to oxidize graphite to obtain graphite oxide. The obtained graphite oxide was pre-purified with aqueous hydrochloric acid (the volume ratio of hydrochloric acid to water was 1:10). Then soak the graphite oxide in absolute ethanol for about 4 hours, then centrifuge to remove the ethanol supernatant, soak the precipitate in ethanol again, and repeat this process 3-5 times. Finally, centrifuge to obtain ethanol-purified graphite oxide.

[0039] (2) Dry the graphite oxide purified by ethanol in the air for about 3 hours, then add water for mechanical stirring for 15 minutes or mild ultrasonic (100W) for 10 minutes to obtain an aqueous solution of graphene oxide, wherein the concentration of graphene oxide is 10 mg / mL.

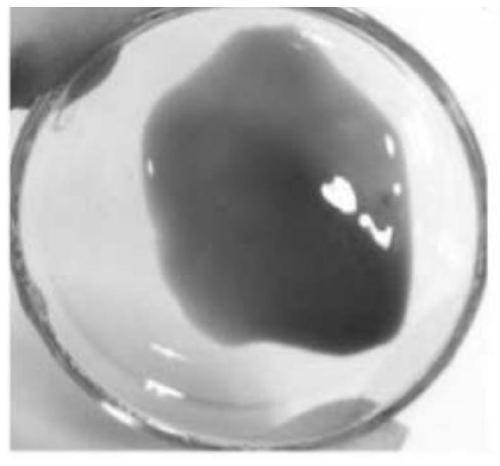

[0040] Pictures of the prepared dispersions are shown in Figure 4 shown. From Figure 4 It can be seen that graphene oxide can also be well disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com