Ultra-wide high-strength high-toughness steel for marine engineering and manufacturing method thereof

A high-strength, high-toughness, marine engineering technology, applied in the field of iron and steel material preparation, can solve the problems of low-temperature toughness not achieving fracture toughness performance, failure to reach, and affecting actual yield, etc., to increase the width range of steel plate products and improve low-temperature fracture toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

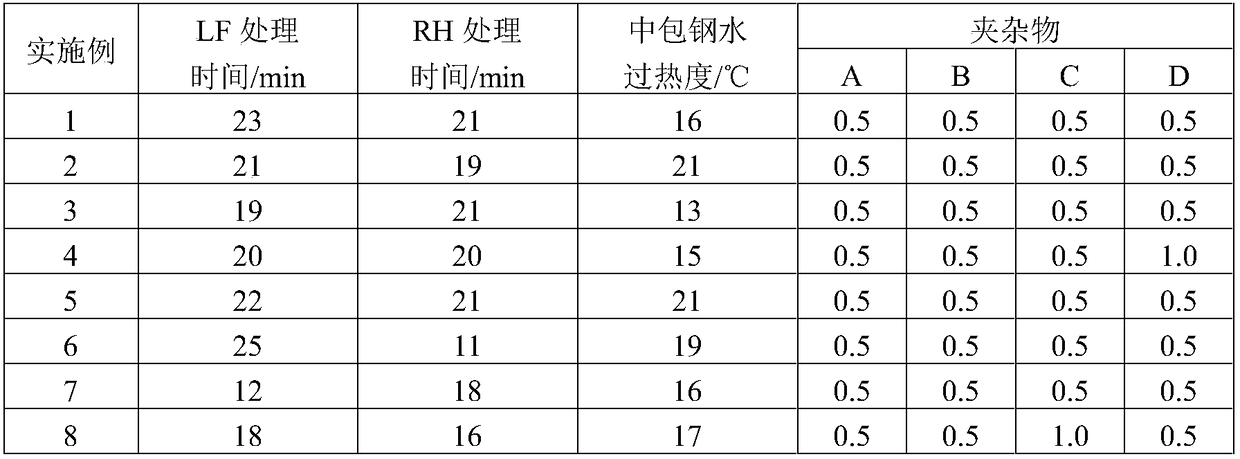

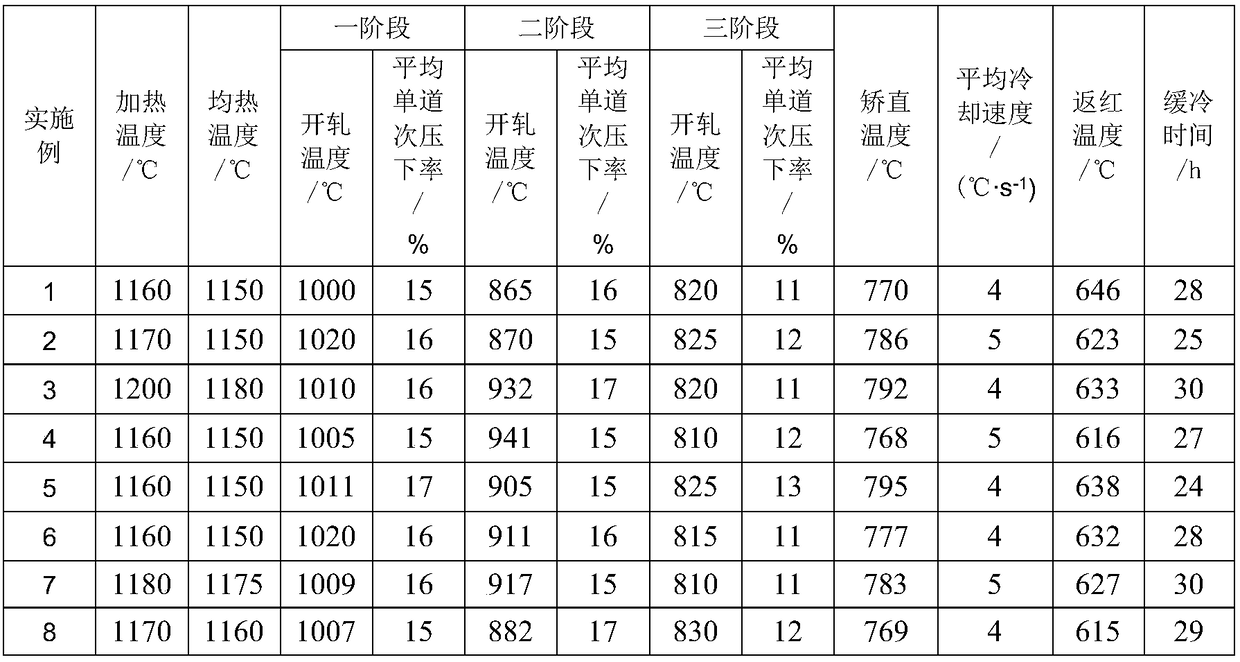

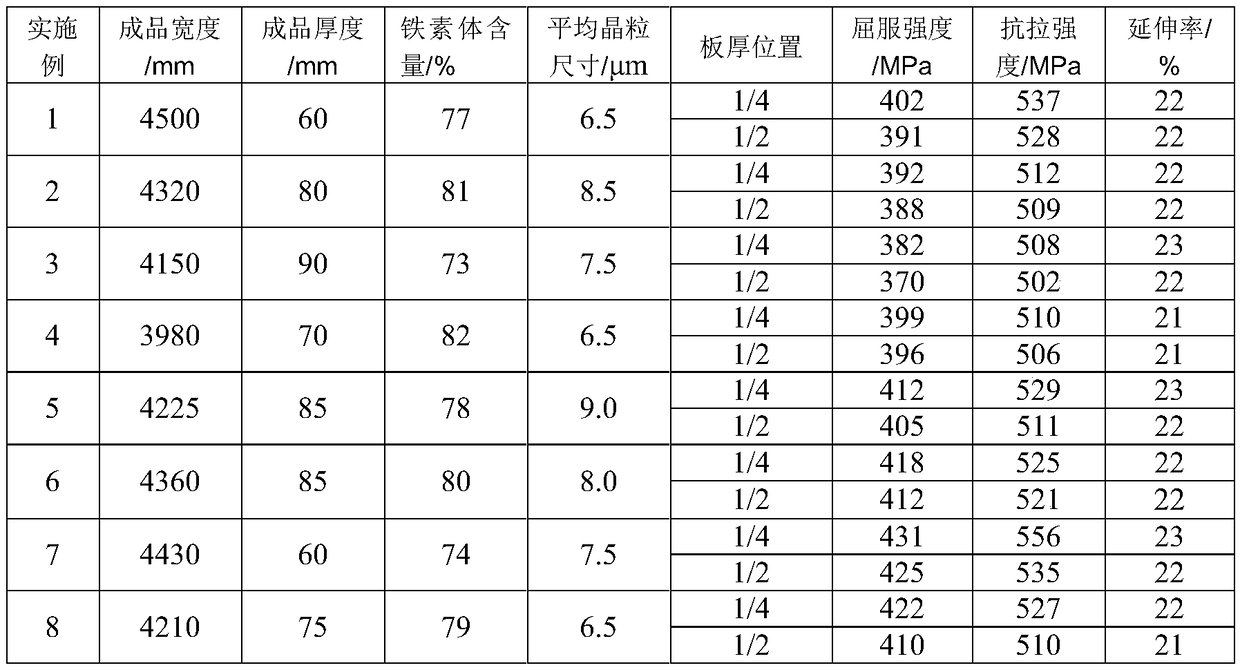

[0034] Table 1 is the chemical composition of the embodiment steel; Table 2 is the smelting process of the embodiment steel; Table 3 is the rolling process of the embodiment steel; Table 4 is the mechanical properties of the embodiment steel; Table 5 is the low temperature of the embodiment steel of the present invention performance and NDTT temperature.

[0035] Table 1 steel chemical composition wt% of the embodiment of the present invention

[0036] Example

C

Si

mn

Cu

Ni

als

Nb

Ti

V

1

0.05

0.42

1.20

0.39

0.16

0.03

0.023

0.012

0.055

2

0.10

0.15

1.33

0.23

0.19

0.05

0.034

0.020

0.046

3

0.07

0.27

1.31

0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com