Mask net tensioning device, evaporation device, net tensioning method and evaporation method

A mask and evaporation technology, which is applied in the field of mask net stretching device, can solve the problems of mask net sagging, high manufacturing and process costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

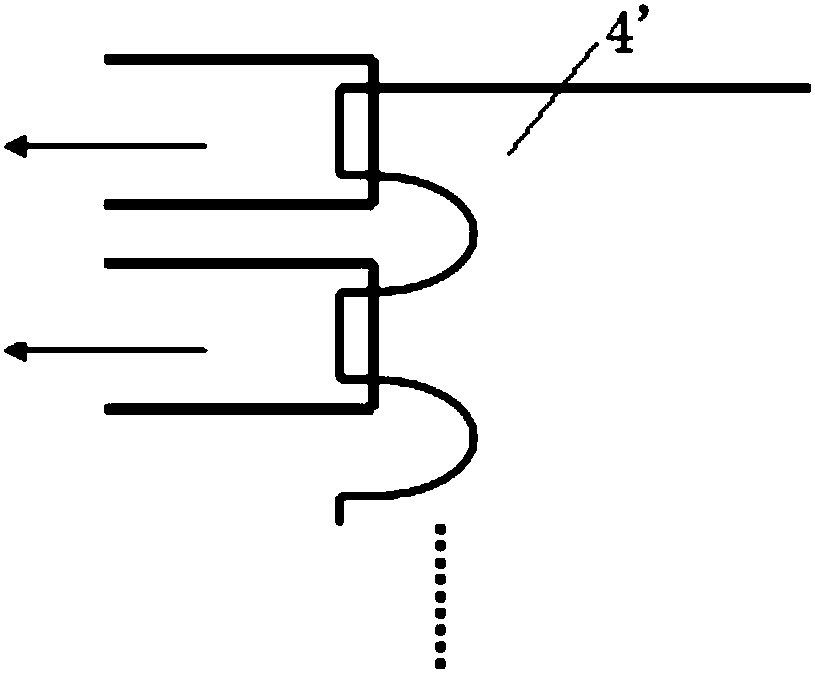

[0034] like Figure 4 As shown, the present invention provides a mask net stretching device, comprising:

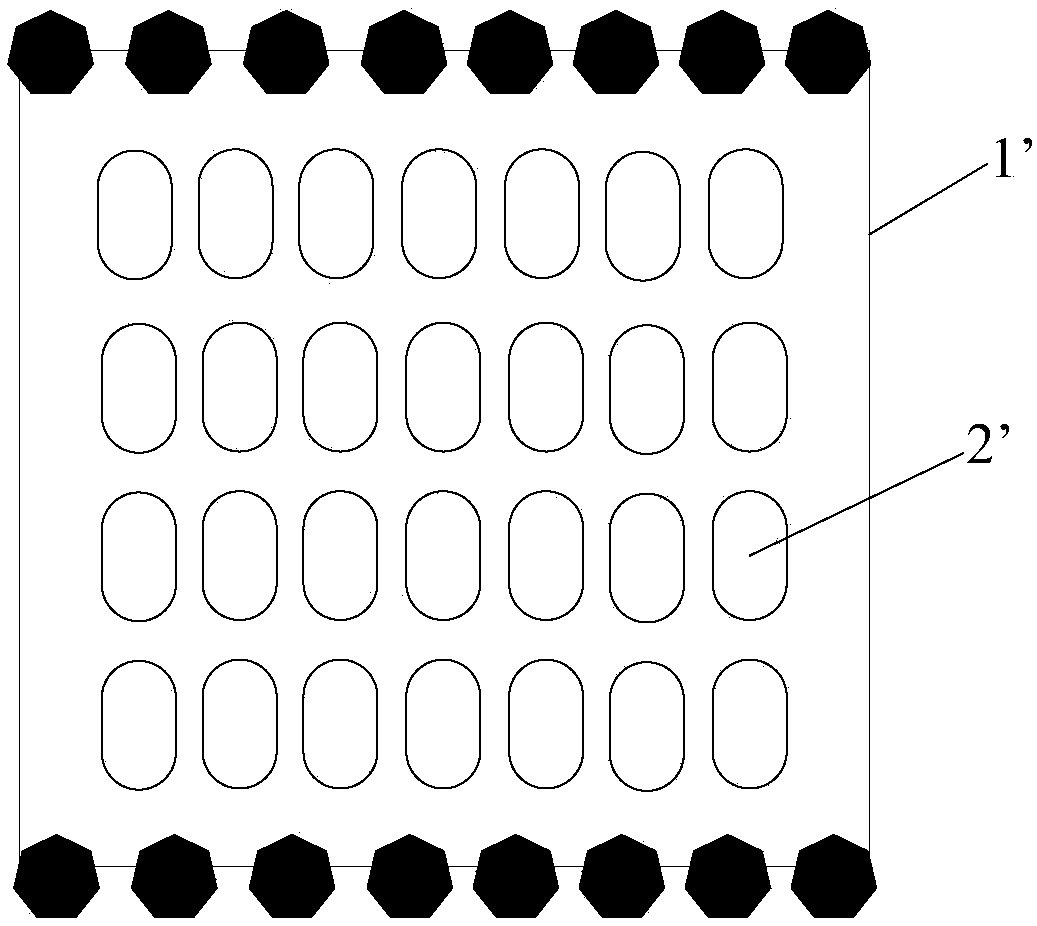

[0035] A mask net 1, the mask net 1 is made of metal material.

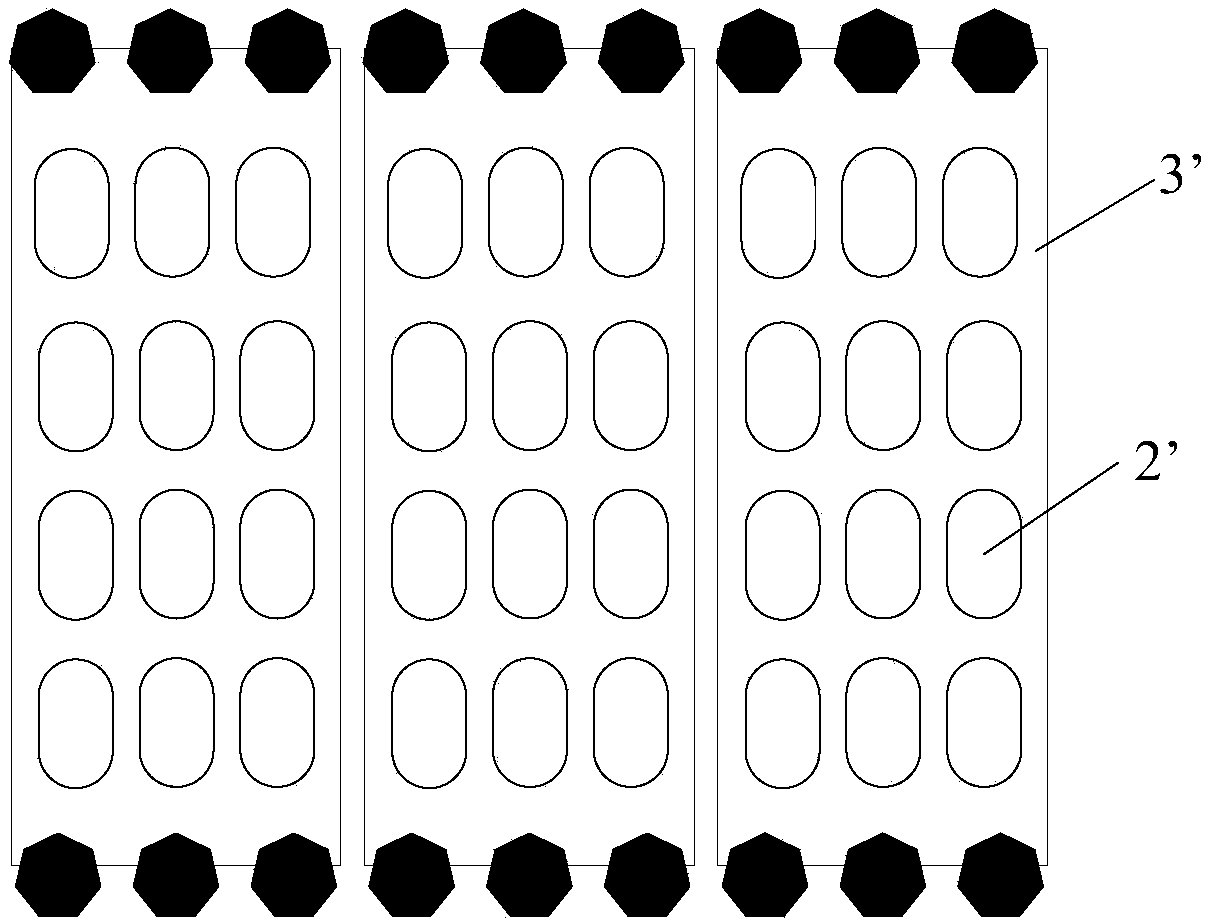

[0036] The tension applying mechanism 3 drives the opposite sides of the mask net 1 to move away or towards each other; the guide mechanism is installed on the opposite sides of the mask net 1 to provide guidance for the movement of the mask net 1; the guide mechanism It includes several sliders 2 and sliding guide rails (not shown in the figure) adapted to the sliders 2, the sliders 2 are distributed on the opposite sides of the mask net 1, and are connected to the tension applying mechanism 3 connect. Specifically, the slider 2 and the mask net 1 are fixed by welding, and drive the opposite sides of the mask net 1 to move to both sides, so as not to sag.

[0037] Preferably, the tension applying mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com