Color changeable knitted fabric production process

A knitted fabric and production process technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems affecting the use range of knitted fabrics, lack of production technology of knitted fabrics, etc., to improve the use range, low cost and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

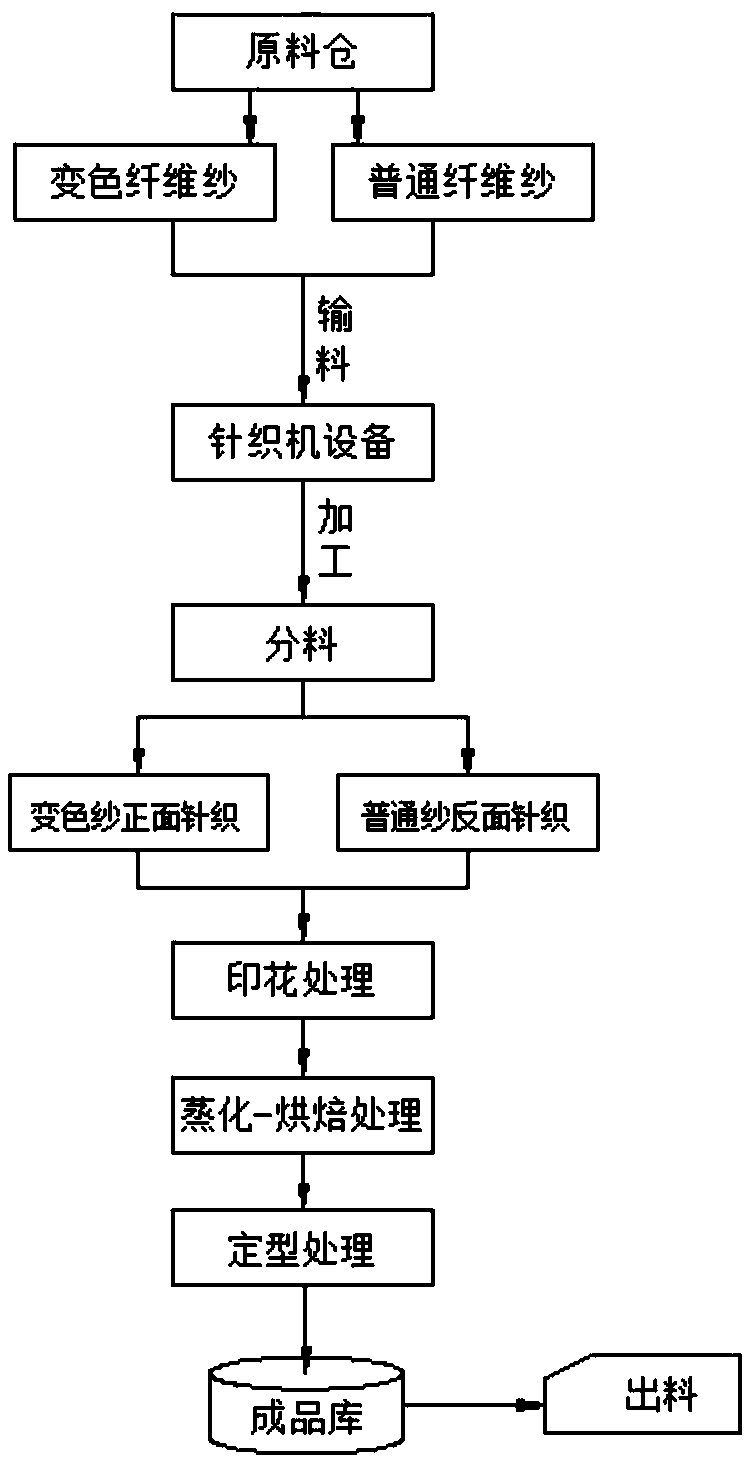

[0024] Such as figure 1 As shown, the present invention provides variable color knitted fabric production technology, comprises the following steps:

[0025] Step 1: Classify and transport the color-changing fiber yarn and ordinary fiber yarn inside the raw material warehouse to the knitting machine equipment for processing;

[0026] Step 2: Automatically classify the color-changing fiber yarn and ordinary fiber yarn inside the knitting machine equipment, wherein the color-changing yarn is on the front side, and the ordinary yarn is on the back side, and the knitting process is performed by the knitting machine;

[0027] Step 3: Carry out printing, steaming-baking, and shaping processes on the processed color-changing knitted fabrics;

[0028] Step 4: Store the finished color-changing knitted fabric in the finished product warehouse for discharging treatment.

[0029] The color-changing fiber yarn in step 1 is prepared by synthetic reaction according to the ratio of 25% of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com