Channel girder composite truss anti-falling structure

A technology of combining trusses and channel beams, which can be used in bridges, protective equipment, buildings, etc., and can solve problems such as lack of rockfall protection types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

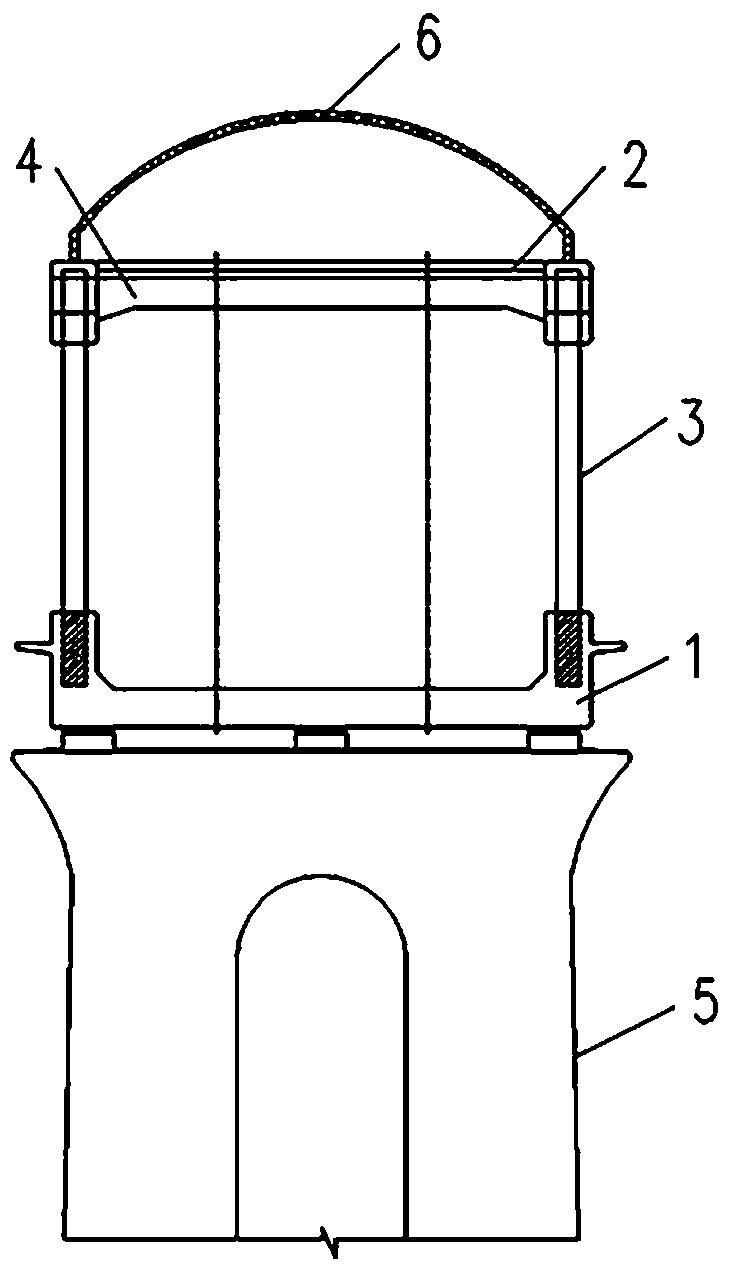

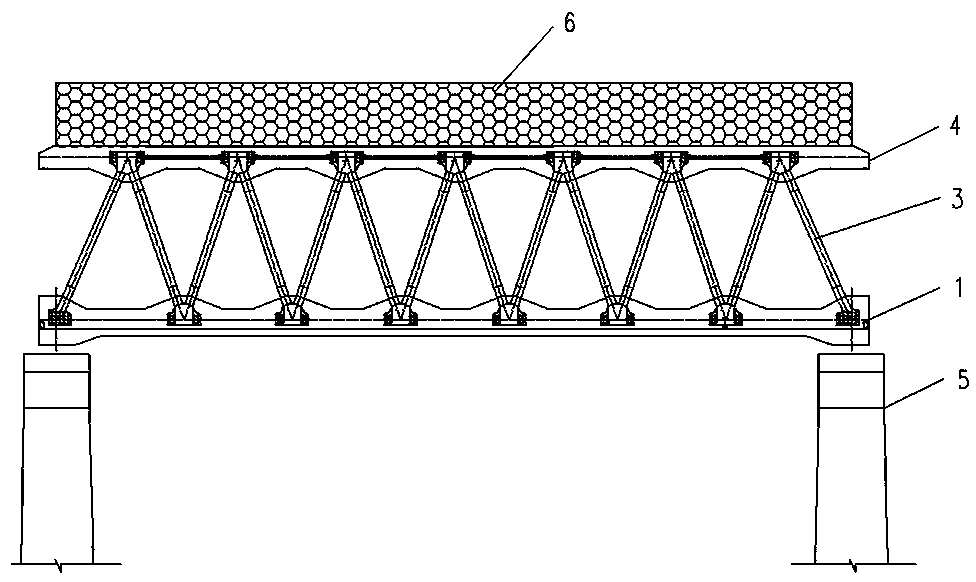

[0028] The invention relates to a rockfall prevention structure of a channel beam composite truss, which comprises a channel beam 1, a steel truss beam 3, a lateral support 4 and a steel grid 2. Vertical and longitudinal steel truss beams 3 are arranged above the ribs on both sides of the channel beam 1, and protective nets or protective vertical plates are hung on the outer sides of the steel truss beams 3. A horizontal support 4 is set between the tops of the steel truss beams 3 on both sides, a steel grid 2 is laid on the top of the horizontal support 4, and a buffer layer such as an aging-resistant rubber layer is laid on the steel grid 2 . The channel beam 1, the steel truss beam 3, the lateral support 4 and the steel grid 2 form a protective space whose cross section is in the shape of a rectangular frame. An arched flexible shed hole 6 is arranged above the transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com