Composite foundation structure applicable to offshore wind power plant fan and construction method

A technology of composite foundation and construction method, which is applied in basic structure engineering, construction, sheet pile wall, etc., can solve the problem of high proportion of fan foundation cost, achieve broad application and development prospects, easy construction, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

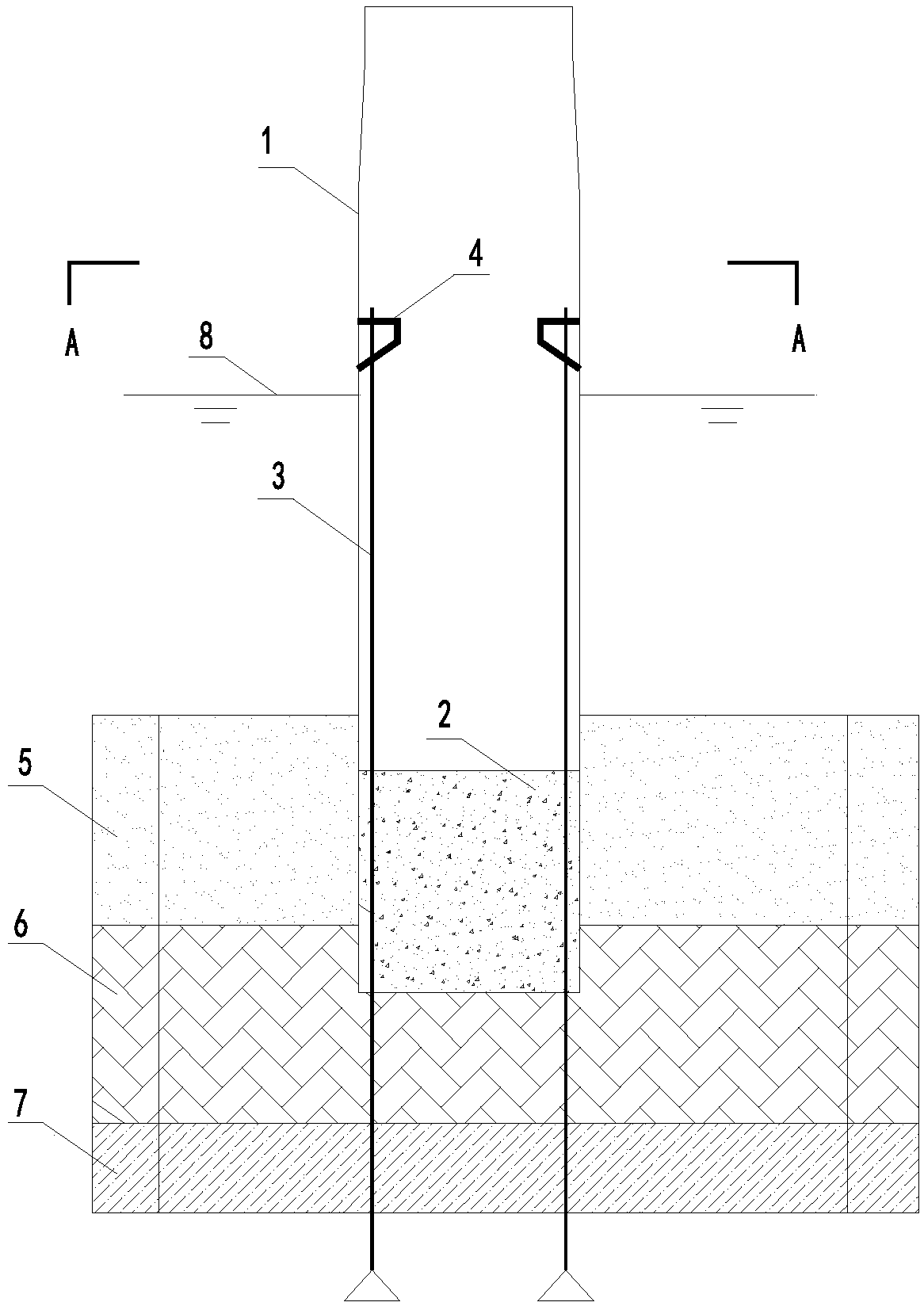

[0030] see figure 1 As shown, the offshore foundation is mainly composed of a covering layer 5 , a solid bearing layer 6 and a slightly weathered rock layer 7 arranged sequentially from top to bottom. The bearing layer 6 can provide support for the steel pipe pile 1 .

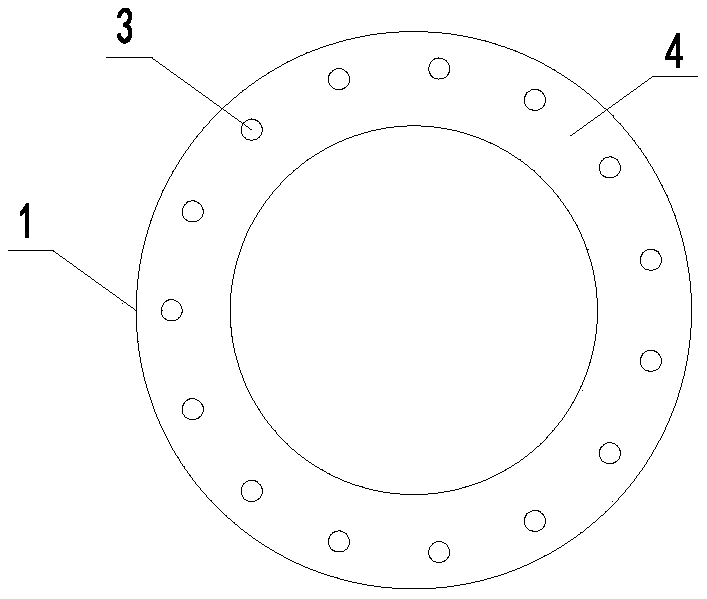

[0031] see figure 1 As shown, the embodiment of the present invention provides a composite foundation structure suitable for wind turbines in offshore wind farms, which includes steel pipe piles 1, core-filled concrete 2 and multiple prestressed anchor cables 3; In the bearing layer 6 of the offshore foundation, the top of the steel pipe pile 1 is connected to the fan structure; the core-filled concrete 2 is poured in the steel pipe pile 1 and placed on the bearing layer 6; the top of the prestressed anchor cable 3 is anchored to the steel pipe On the inner wall of the pile 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com