A two-stage vane ring assembly with adaptive thermal expansion for flue gas turbines

A flue gas turbine and vane ring technology, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problem of affecting the rotor series motion and load, the difficulty of disassembling and replacing blades, and affecting the safety, reliability and stability of the flue gas turbine Work and other problems, to achieve the effect of improving efficiency, improving assembly efficiency and working reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

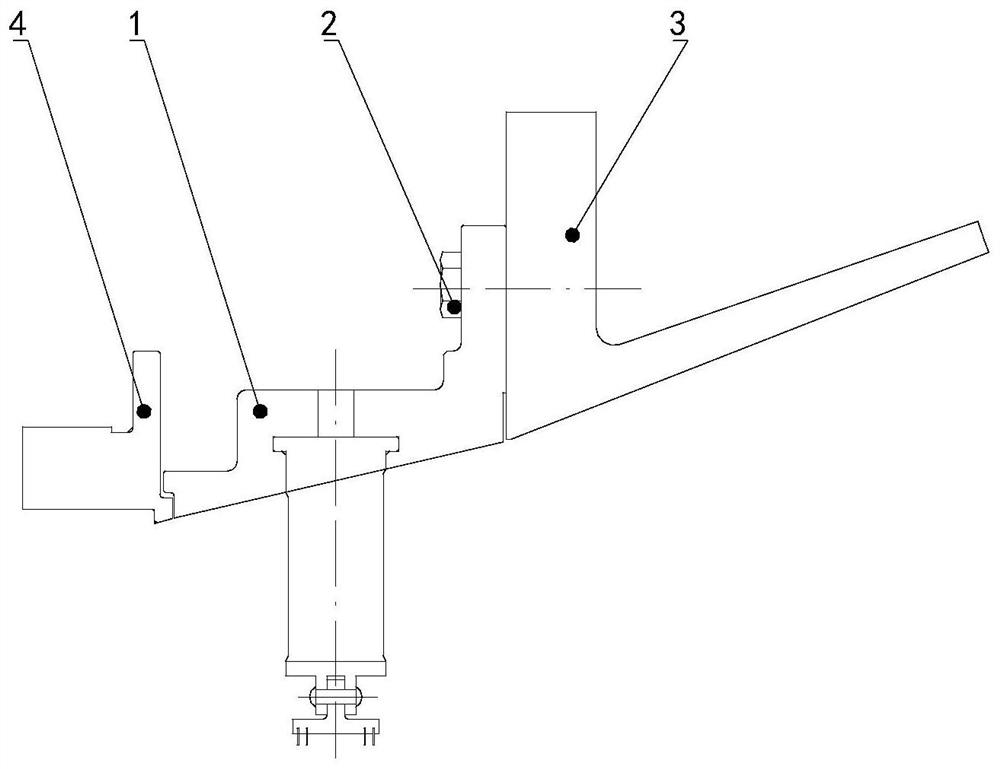

[0030] like Figure 1 to Figure 5 As shown, the present invention provides a second-stage vane ring assembly for self-adaptive thermal expansion of a flue gas turbine. Between the body diffuser assembly 3.

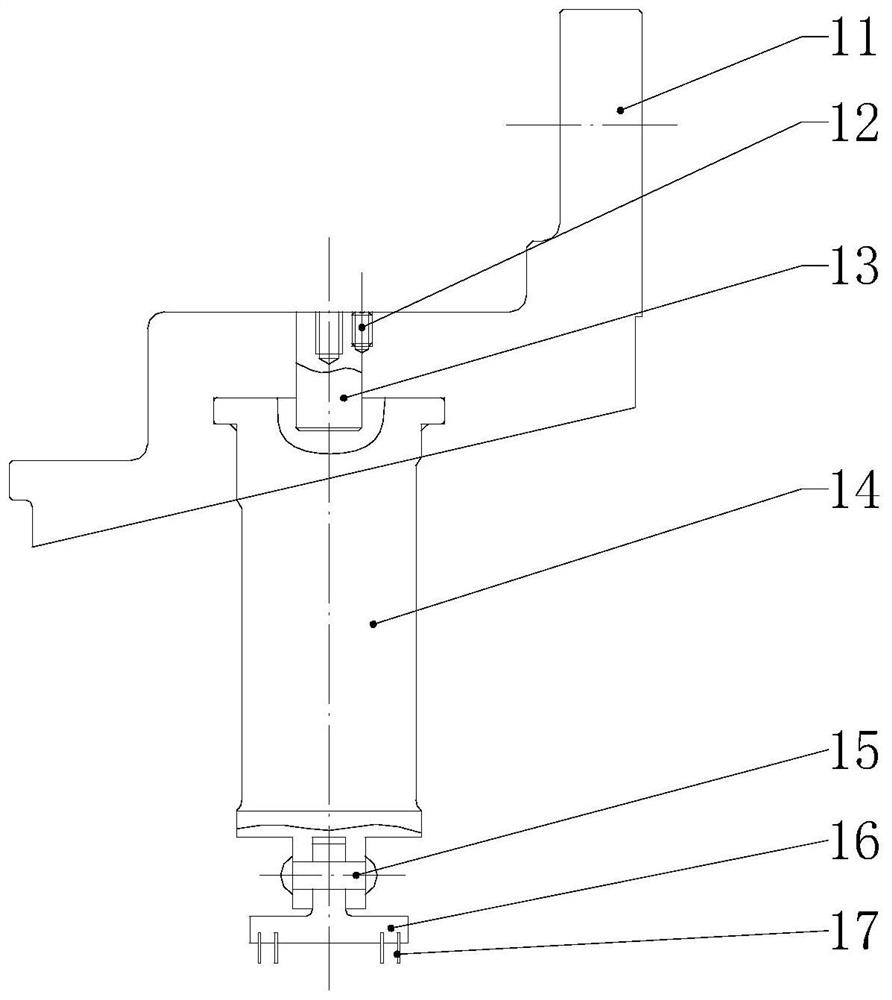

[0031] Secondary vane ring assembly 1 (eg image 3 (shown) includes secondary stationary vane fixing ring 11 , fixing screw 12 , second positioning pin 13 , secondary stationary vane 14 , round head rivet 15 , sealing ring assembly 16 and sealing piece 17 . The secondary vane ring assembly 1 is a cantilever support structure with one end fixed and one end freely expandable. It is fixed on the diffuser assembly 3 of the exhaust casing with the hexagon screw 2 . The Z-shaped structure is used to freely expand and connect with the primary vane ring assembly 4 (such as figure 1 shown).

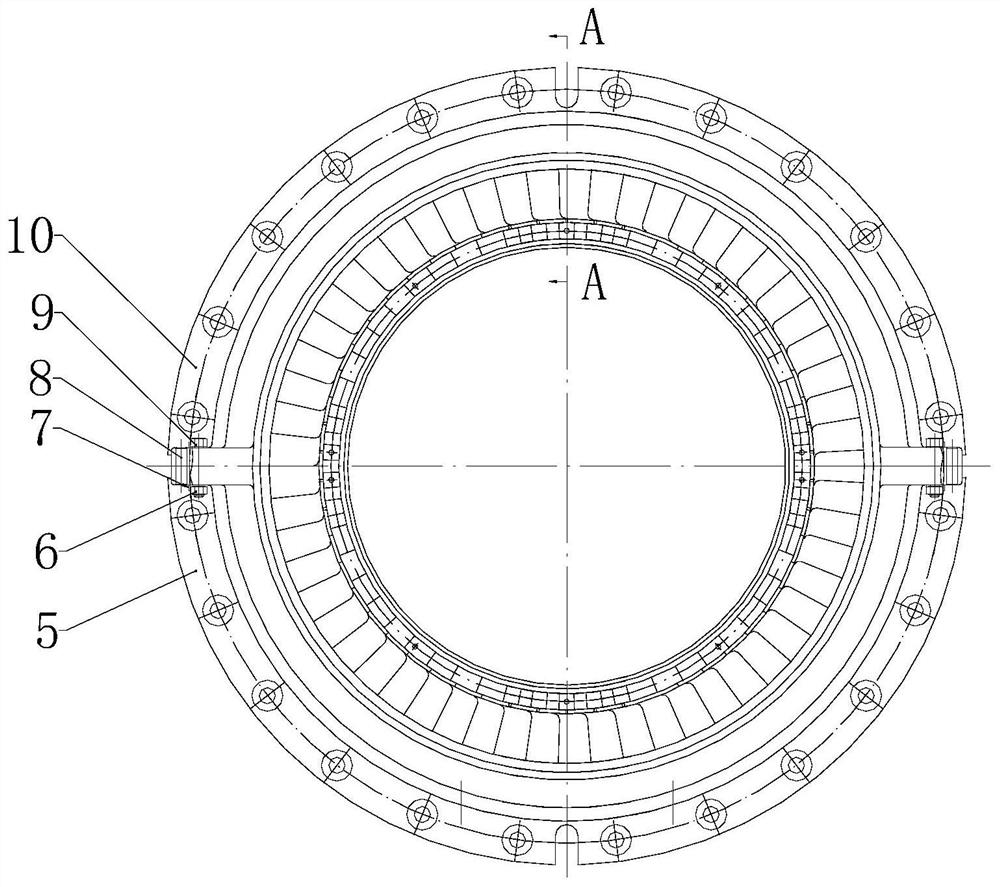

[0032] Secondary vane fixing ring 11 (such as figure 2 shown) is machined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com