Diaphragm compressor and flow regulating method thereof

A diaphragm compressor and diaphragm technology, applied in the field of diaphragm compressors, can solve the problems of high energy consumption and high cost, and achieve the effects of solving insufficient suction, reducing energy consumption and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0050] Since the existing oil replenishment method can only replenish oil at a certain fixed position in a cycle, the air volume cannot be adjusted, which will cause the problem of insufficient air intake. However, the existing air volume adjustment method has the disadvantages of high cost and high energy consumption.

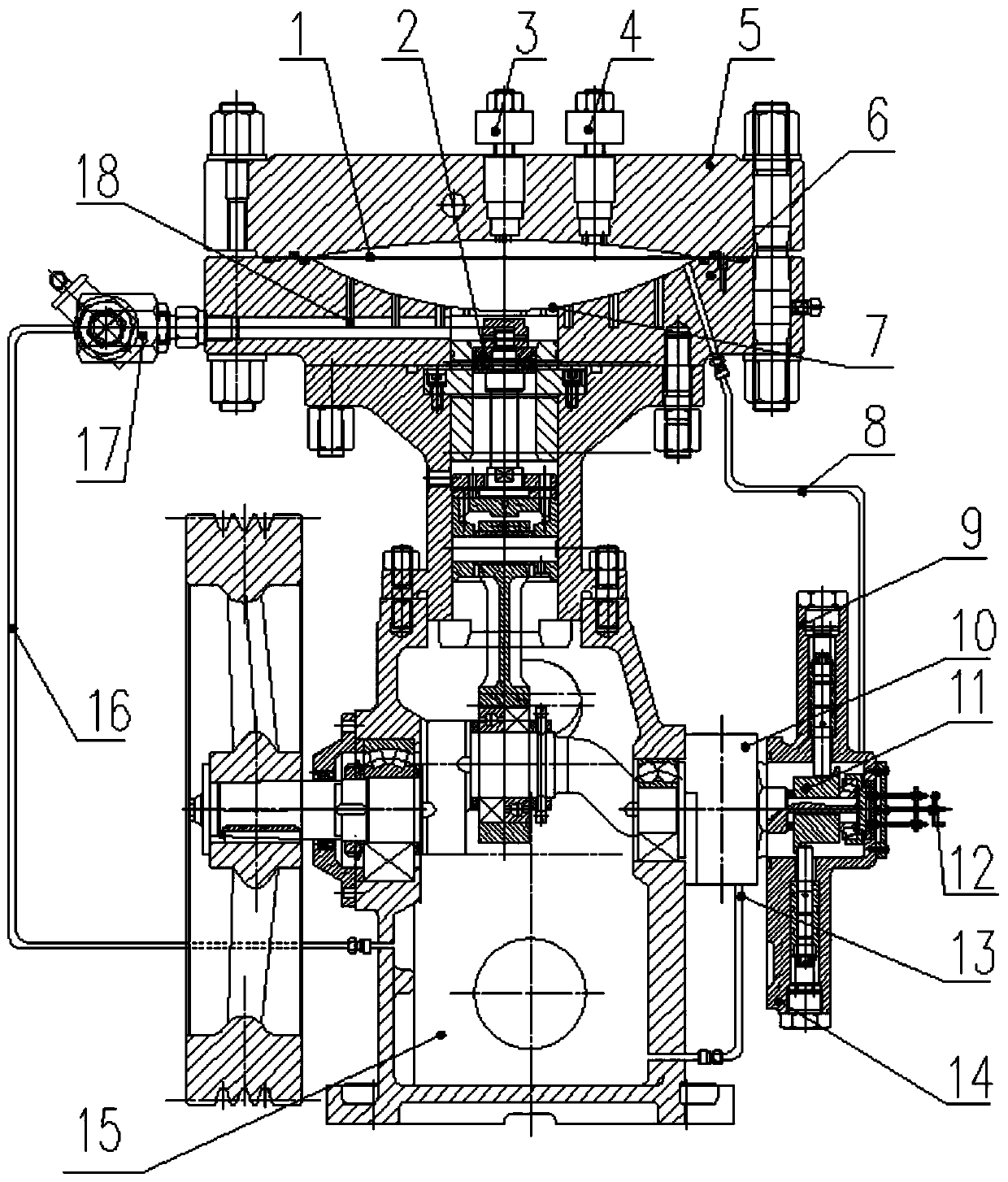

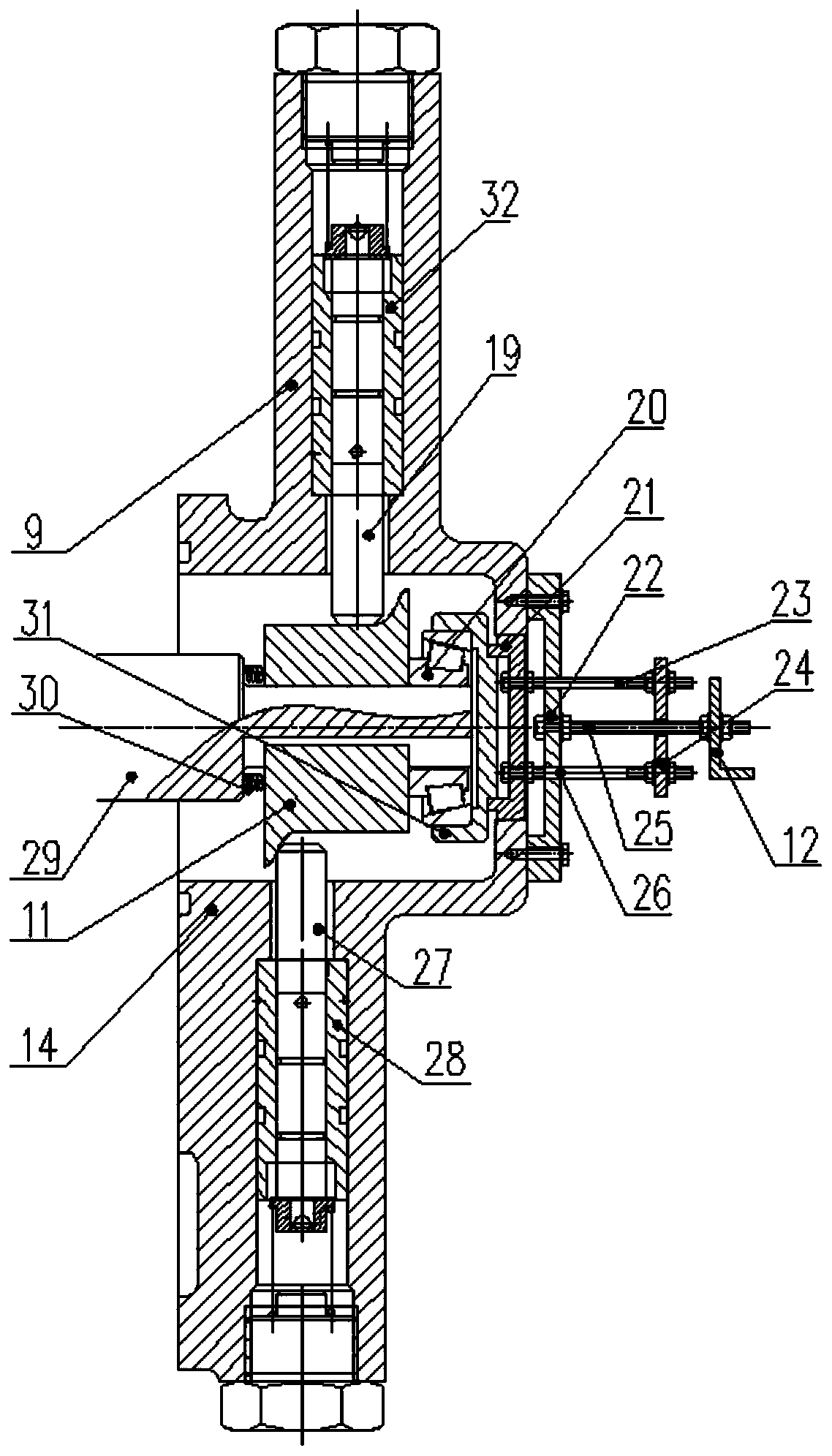

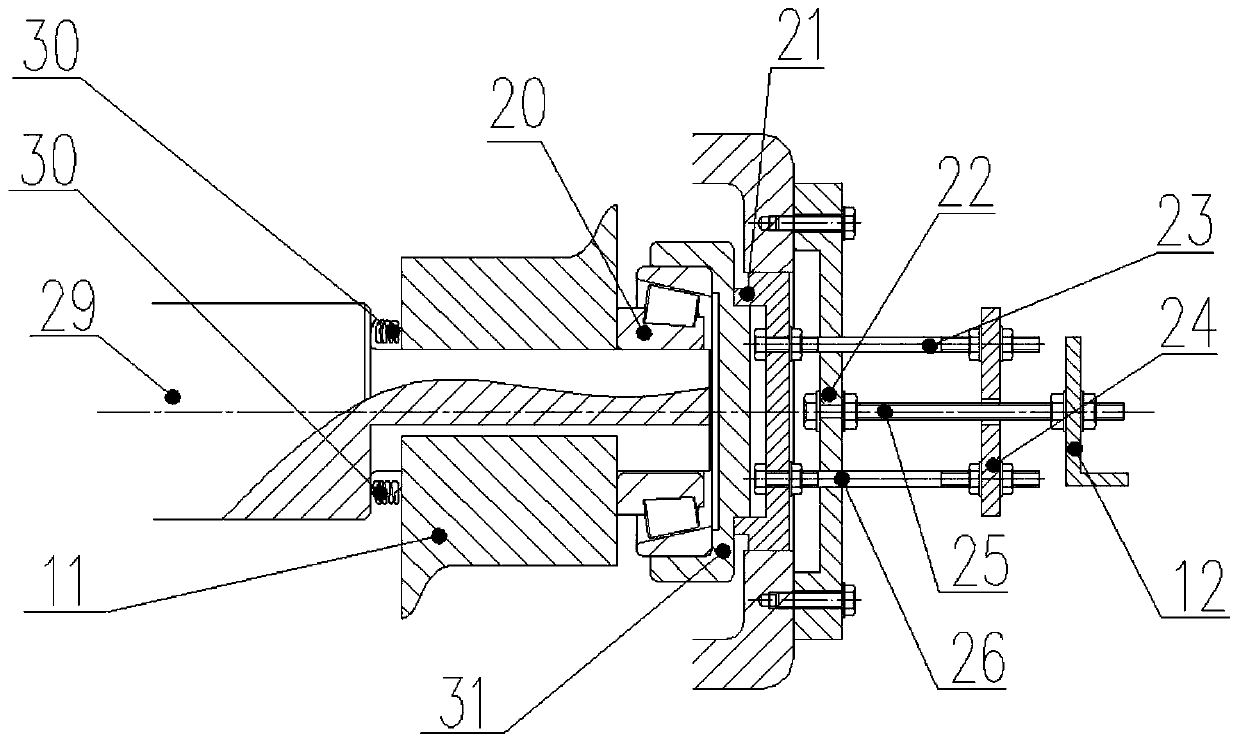

[0051] see figure 1 , The diaphragm compressor of the present invention is mainly composed of a motor, a base, a crankcase, a crankshaft connecting rod movement mechanism, cylinder parts, oil and gas pipelines, an electric control system and some accessories, which are not specifically limited by the present invention.

[0052] The cylinder part includes a diaphragm 1, a piston 2, a cover plate 5 and a support plate 6. The cover plate 5 with a dome-shaped inner surface and the support plate 6 with a dome-shaped surface are connected to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com