Micro-combustor for visualization research

A micro-combustion and burner technology, applied in the directions of burners, gas fuel burners, combustion methods, etc., can solve the problems of cumbersome steps, and achieve the effect of simple fastening method and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

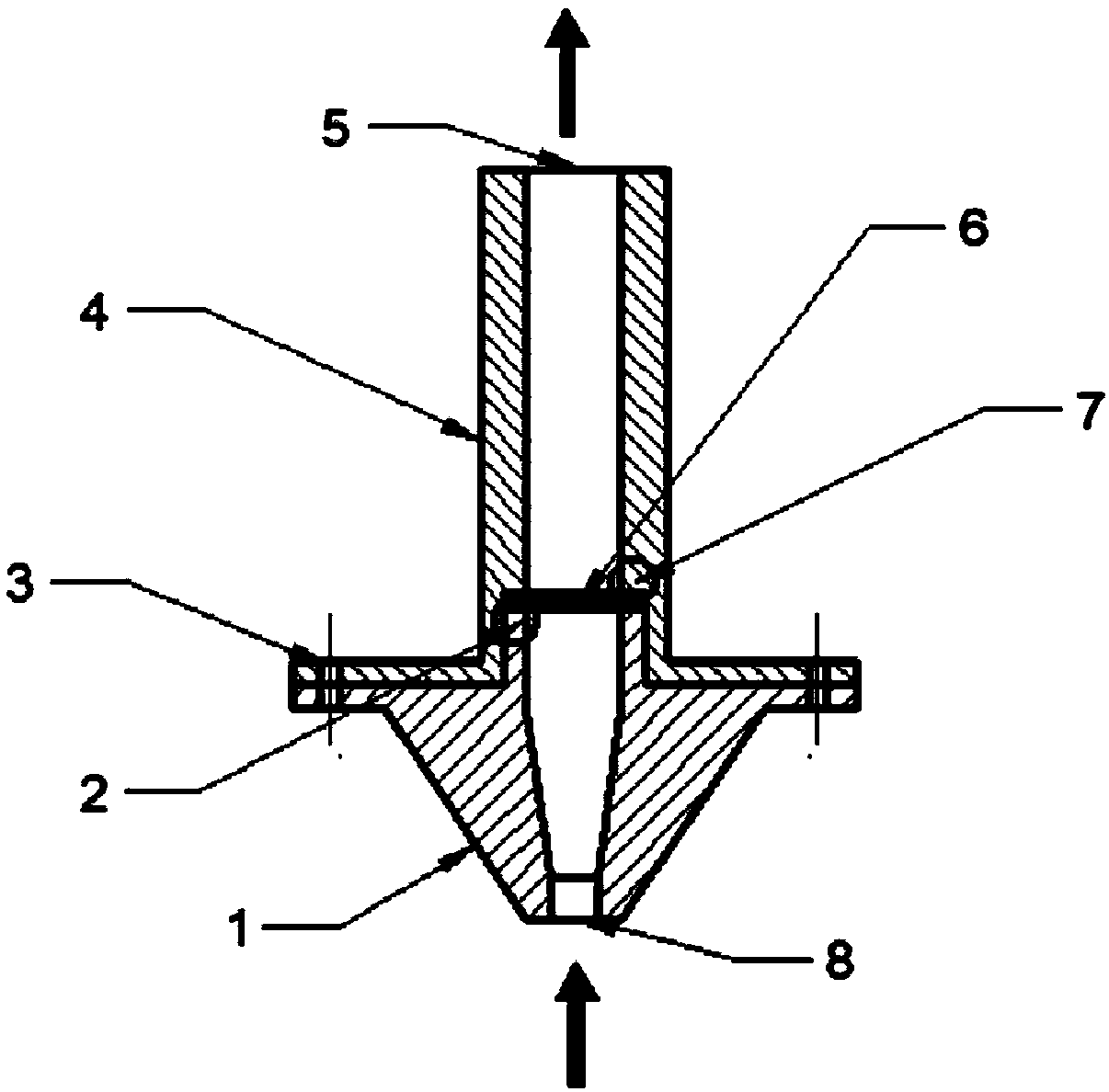

[0038] Such as figure 1 As shown, a micro-burner for visualization research is characterized in that it includes a base 1, a boss 2, a threaded hole 3, a burner 4, a filter screen 6 and a groove 7;

[0039] The lower end of the base 1 is a gas inlet 8, and the other end is a boss 2;

[0040] The upper end of the burner 4 is an air outlet 5 installed on the base 1 through a threaded hole 3 and connected;

[0041] A filter screen 6 is arranged between the boss 2 and the groove 7.

[0042] The working principle of a micro-burner for visualization research according to the present invention is: during operation, hydrocarbon fuel and oxidant enter from the intake port of the base, and are mixed inside, and then pass through filters of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com