Lightweight material pressed and molded composite basin firework

A light-weight material and projectile technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of undiscovered combined potted flower projectiles, etc., and achieve the effects of improving overall economic benefits, increasing stability, and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be described in more detail with reference to the drawings and specific embodiments.

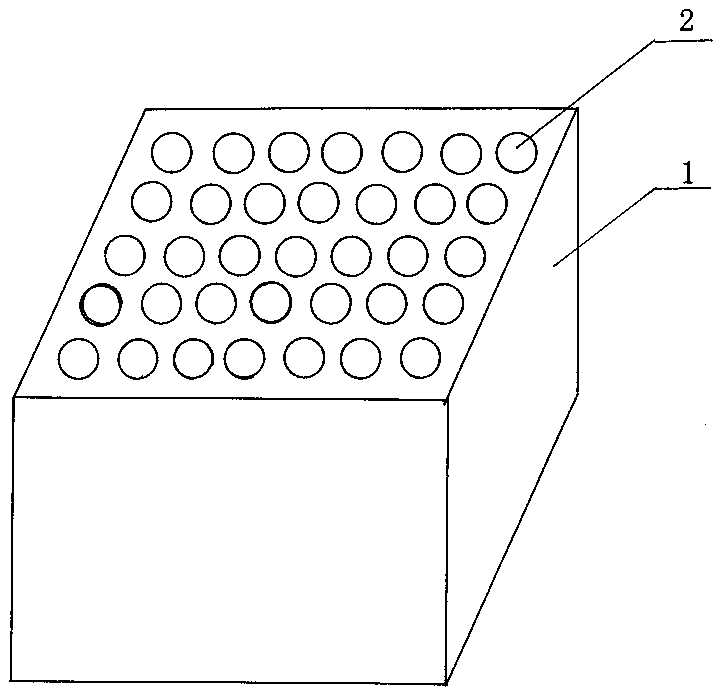

[0021] figure 1 Embodiments of the invention are shown. Its composition: it consists of a projectile body 1 and a barrel hole 2. The structural features of the specific embodiment are:

[0022] A combined potted flower emitter with molded configuration of lightweight materials is used for launching and setting off firework effects. There are several open cylinder holes 2, which can make the firework effect body be placed in the cylinder holes for fixed emission.

[0023] In the embodiment of the present invention, the number of the cylinder holes 2 on the emitter 1 and the arrangement and configuration of the cylinder holes 2 are arranged in any combination according to the requirements of the fireworks display combination.

[0024] In the embodiment of the present invention, the external shape of the emitter 1 is a square, or a cylinder, or an el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com