Electromechanical system preventive maintenance method and system, apparatus, and storage medium

A preventive maintenance, electromechanical system technology, applied in the field of electromechanical systems, can solve the problems of low reliability and efficiency of building electromechanical systems and equipment, repeated failures, and failure to deal with faults, so as to avoid major equipment failures and reduce failures. The frequency of occurrence and the effect of good maintenance timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

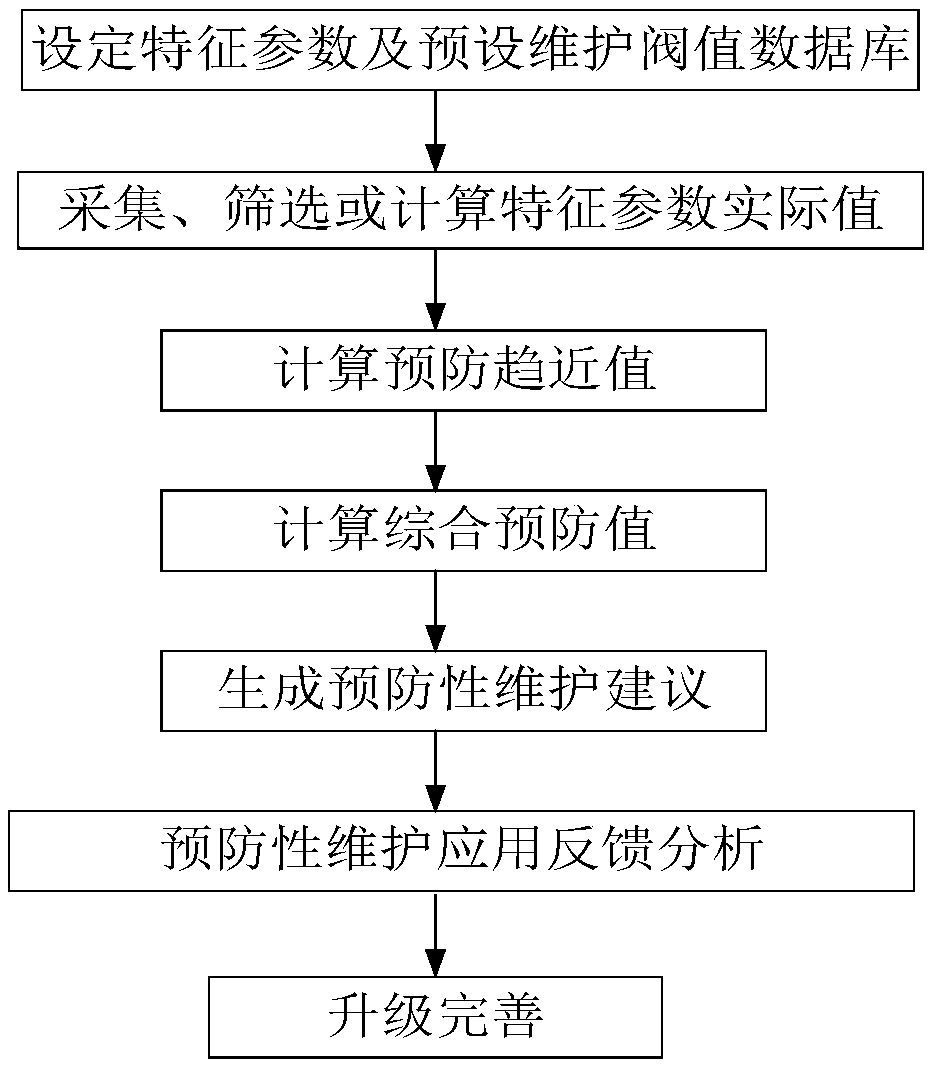

[0038] A preventive maintenance method for an electromechanical system, comprising the following steps:

[0039] The data acquisition step is to obtain the values corresponding to a plurality of characteristic parameters of the electromechanical equipment of the electromechanical system;

[0040] The step of obtaining the preventive approach value is to obtain multiple preventive approach values according to the value corresponding to the characteristic parameter and the preset maintenance threshold, and use the ratio of the value corresponding to the characteristic parameter to the preset maintenance threshold as the preventive approach value of the characteristic parameter, and the characteristic parameter One-to-one correspondence with preset maintenance thresholds;

[0041] The comprehensive preventive value acquisition step is to obtain the comprehensive preventive value of the electromechanical equipment according to the preventive approach value of multiple characte...

Embodiment 2

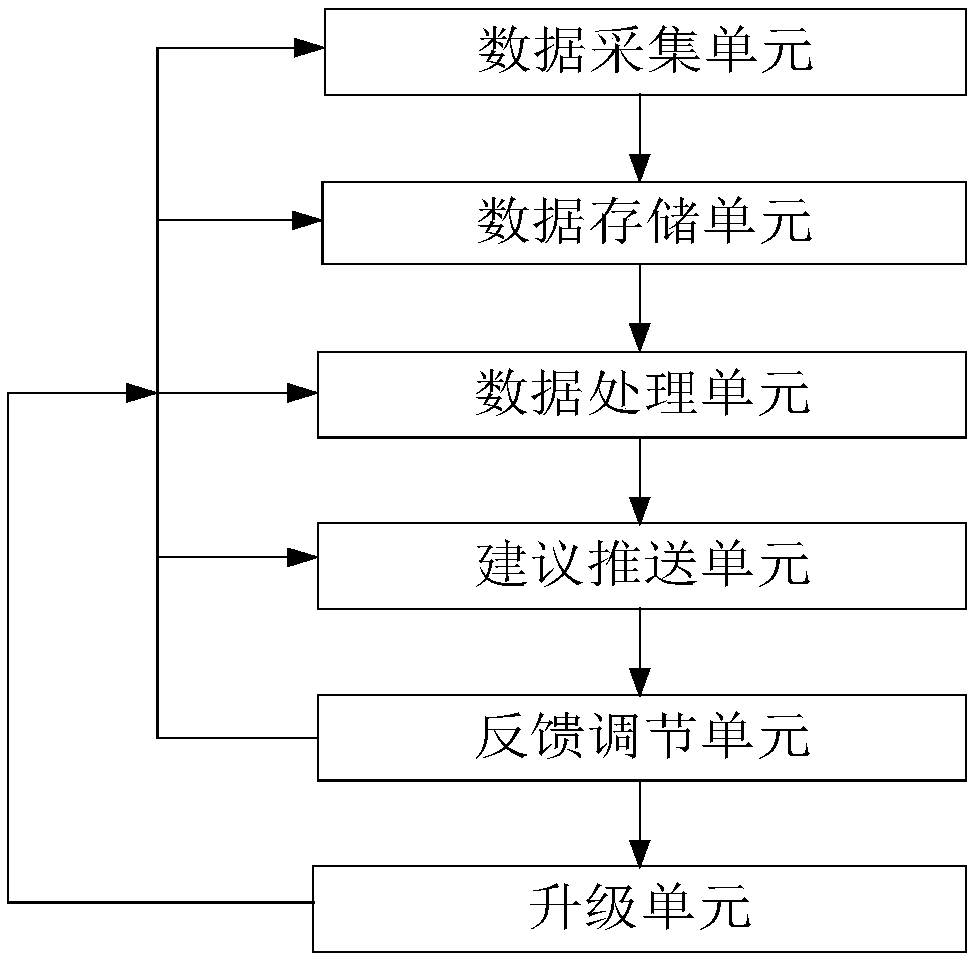

[0074] A preventive maintenance system for electromechanical systems, comprising:

[0075] A data acquisition unit, configured to acquire values corresponding to a plurality of characteristic parameters of the electromechanical equipment of the electromechanical system;

[0076] The preventive approach value acquisition unit is used to obtain a plurality of preventive approach values according to the value corresponding to the characteristic parameter and the preset maintenance threshold, and uses the ratio of the value corresponding to the characteristic parameter to the preset maintenance threshold as the preventive approach value of the characteristic parameter, One-to-one correspondence between characteristic parameters and preset maintenance thresholds;

[0077] A comprehensive preventive value acquisition unit is used to obtain the comprehensive preventive value of the electromechanical equipment according to the preventive approach value of multiple characteristic p...

Embodiment 3

[0091] A preventive maintenance equipment for electromechanical systems, including:

[0092] at least one processor; and,

[0093] a memory communicatively coupled to the at least one processor; wherein,

[0094] The memory stores instructions executable by the at least one processor, the instructions being executed by the at least one processor, to enable the at least one processor to perform the method of preventive maintenance of an electromechanical system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com