A method for determining the number of gas production wells in a gas storage tank considering the productivity change of gas wells

A determination method and technology of gas storage, applied in the direction of data processing applications, instruments, resources, etc., can solve the problems of not considering the change of the number of gas production wells and the inability to accurately calculate the number of gas production wells of the gas storage, so as to save investment, Avoid investment waste and calculate accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for determining the number of gas production wells in a gas storage that considers changes in gas well productivity, including the following steps:

[0038] Step 1) According to the production capacity test data in the gas storage construction area, select two production data points, substitute them into the gas well productivity equation, and solve the coefficients a and b of the gas well productivity equation;

[0039] Step 2) Determine the bottomhole flow pressure of the gas well under different daily gas production according to the wellbore pipe flow equation and the gas production wellhead pressure;

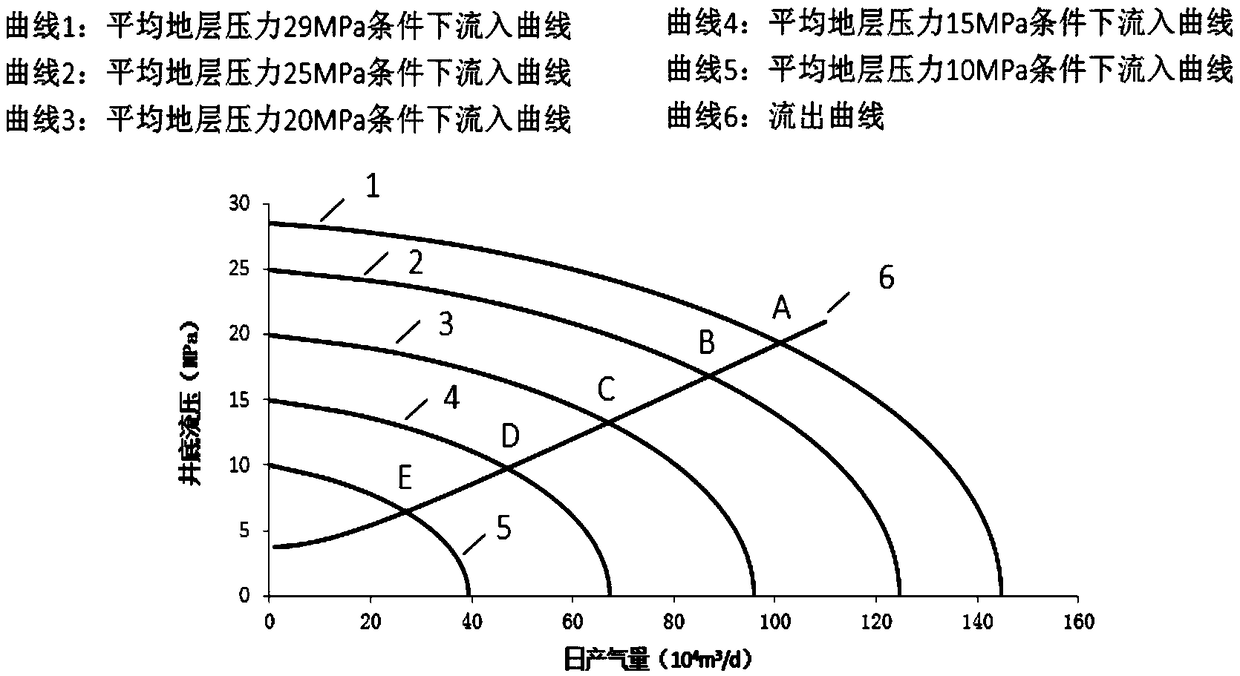

[0040] Step 3) In the same coordinate system, draw different average formation pressure P according to the gas well productivity equation e Under the condition, the daily gas production q and the bottom hole pressure P wf At the same time, according to the wellbore pipe flow equation, the daily gas production q of the gas production ...

Embodiment 2

[0050] On the basis of Embodiment 1, this embodiment provides a method for determining the number of gas production wells in a gas storage that considers the change in gas well productivity, including the following steps:

[0051] Step 1. According to the production dynamic data and productivity well test data of gas wells in the construction area of the gas storage, select two production data points and substitute them into the productivity equation. After the simultaneous equations, the coefficients a and b of the gas well productivity equation are solved; The monthly deceleration rate of production is less than 5%, and the monthly deceleration rate of bottom hole pressure is less than 3%;

[0052] First production data point:(P e1 ,P wf1 ,q 1 );

[0053] Second production data point: (P e2 ,P wf2 ,q 2 );

[0054] Capacity equation:

[0055] Among them, P e1 is the average formation pressure of production data point 1, MPa; P wf1 is the bottomhole flowing press...

Embodiment 3

[0072] This embodiment further describes the present invention through the determination of the number of gas production wells in a certain gas storage. The determination steps are as follows:

[0073] Step 1. Using the well test data of a certain gas storage to obtain the gas well productivity equation:

[0074]

[0075] Step 2. Select tubing size 3 1 / 2 in, wellhead pressure 3MPa to determine the wellbore flow equation.

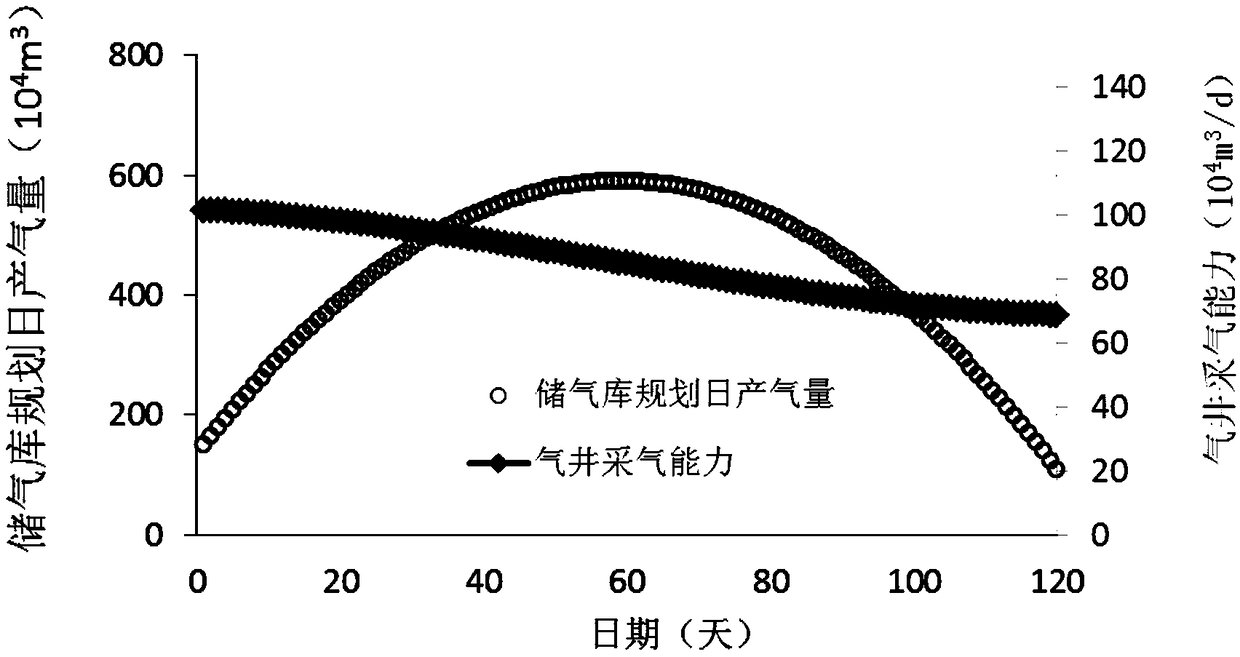

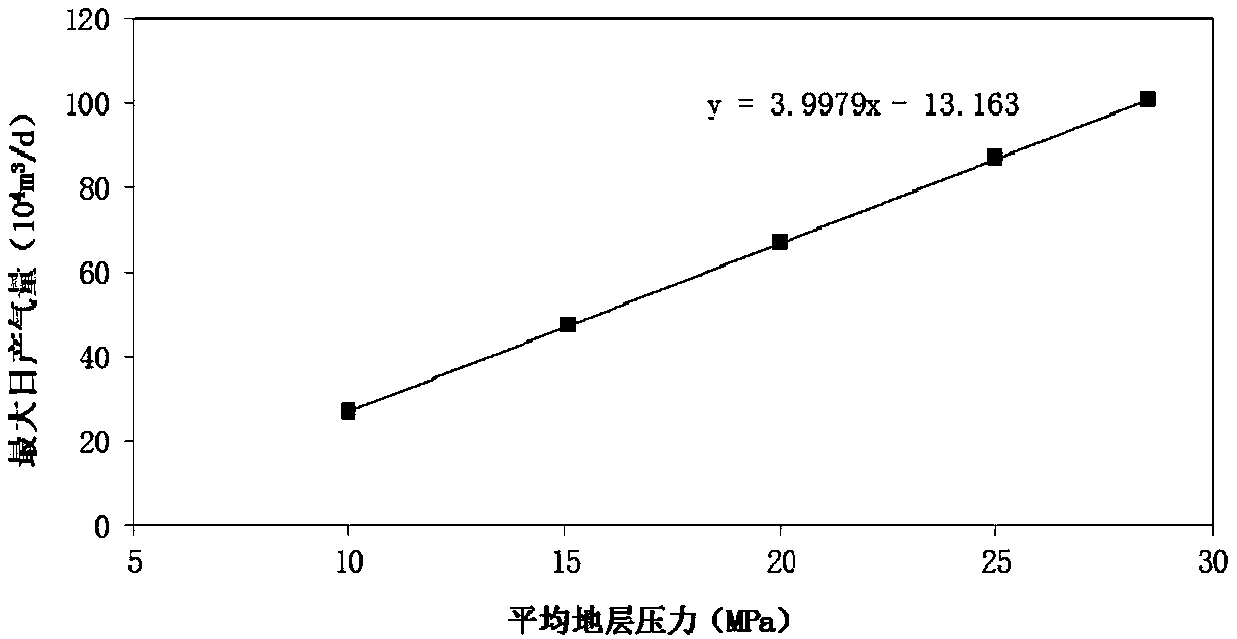

[0076] Step 3, according to gas well productivity equation and flow equation draw inflow and outflow curve intersection chart (see figure 2 ), select 5 junctions A(100, 19.2, 29), B(85, 16.5, 25), C(65, 12.8, 20), D(45, 9.4, 15), E(25, 6.1, 10 ), where A point means that when the average formation pressure is 29MPa, the bottomhole flow pressure of the gas well is 19.2MPa, and the reasonable daily gas production of the gas well is 100×10 4 m 3 / d, other junctions have similar meanings. According to the average formation pressure of the intersecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com