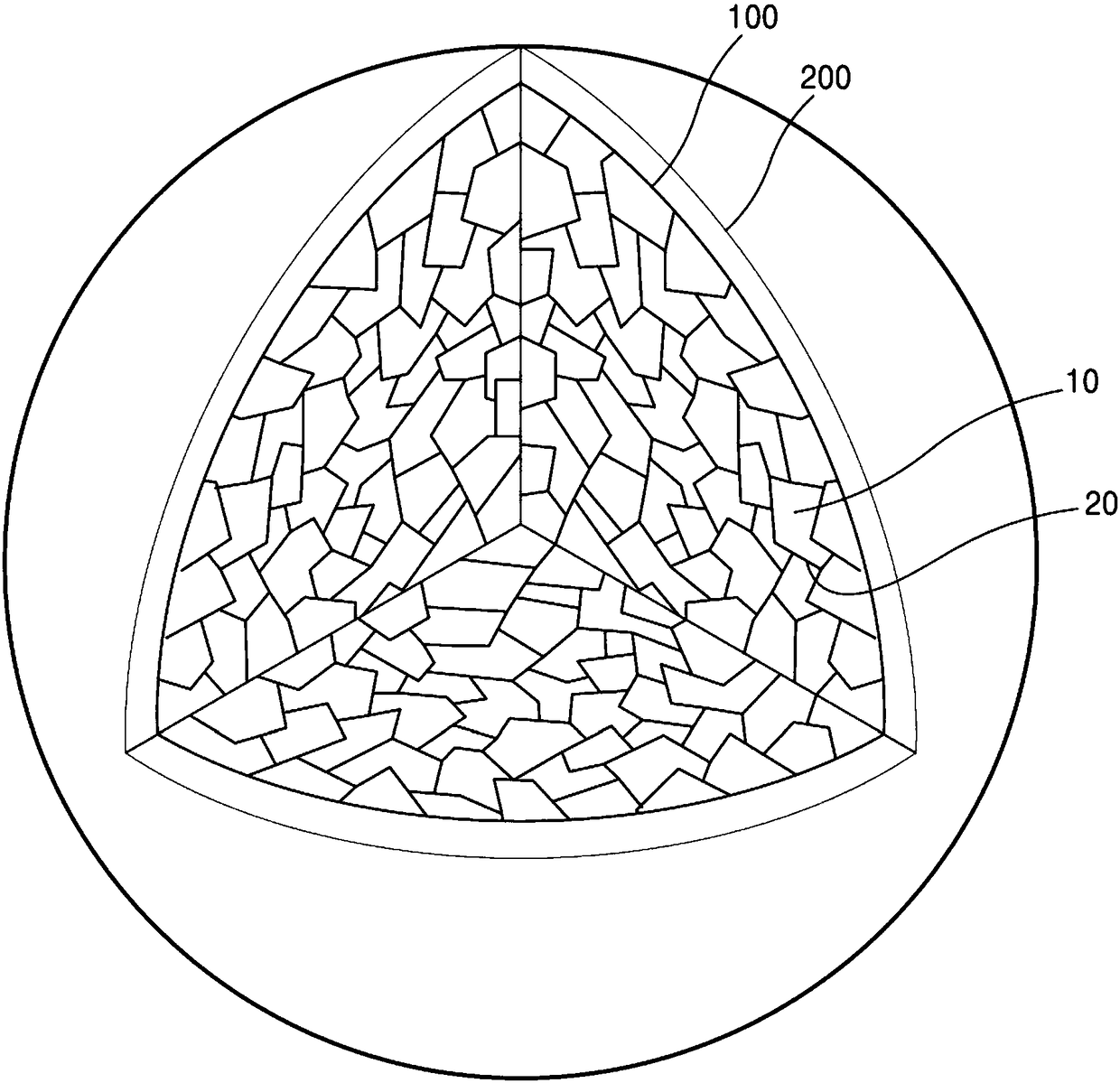

Composite cathode active material, cathode and lithium battery including the same, and method of preparing the composite cathode active material

A technology of active material and composite positive electrode, which is applied in the field of preparing the composite positive electrode active material and can solve the problems of poor thermal stability, poor life-span characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0133] In the preparation of the mixture, the amount of the solution may be about 50 parts by weight or less, about 45 parts by weight or less, about 40 parts by weight or less, about 35 parts by weight or less, about 30 parts by weight parts or less, about 25 parts by weight or less, about 20 parts by weight or less, or about 10 parts by weight or less, based on 100 parts by weight of the nickel-containing first lithium transition metal oxide. In the mixture, as the concentration of the first lithium transition metal oxide increases, coating the surface and interior of the composite cathode active material can be uniformly performed.

[0134] In the preparation of the mixture, the amount of solvent contained in the solution may be less than about 50 parts by weight, about 45 parts by weight or less, about 40 parts by weight or less, about 35 parts by weight or less, about 30 parts by weight or less, about 25 parts by weight or less, about 20 parts by weight or less, or about ...

Embodiment 1

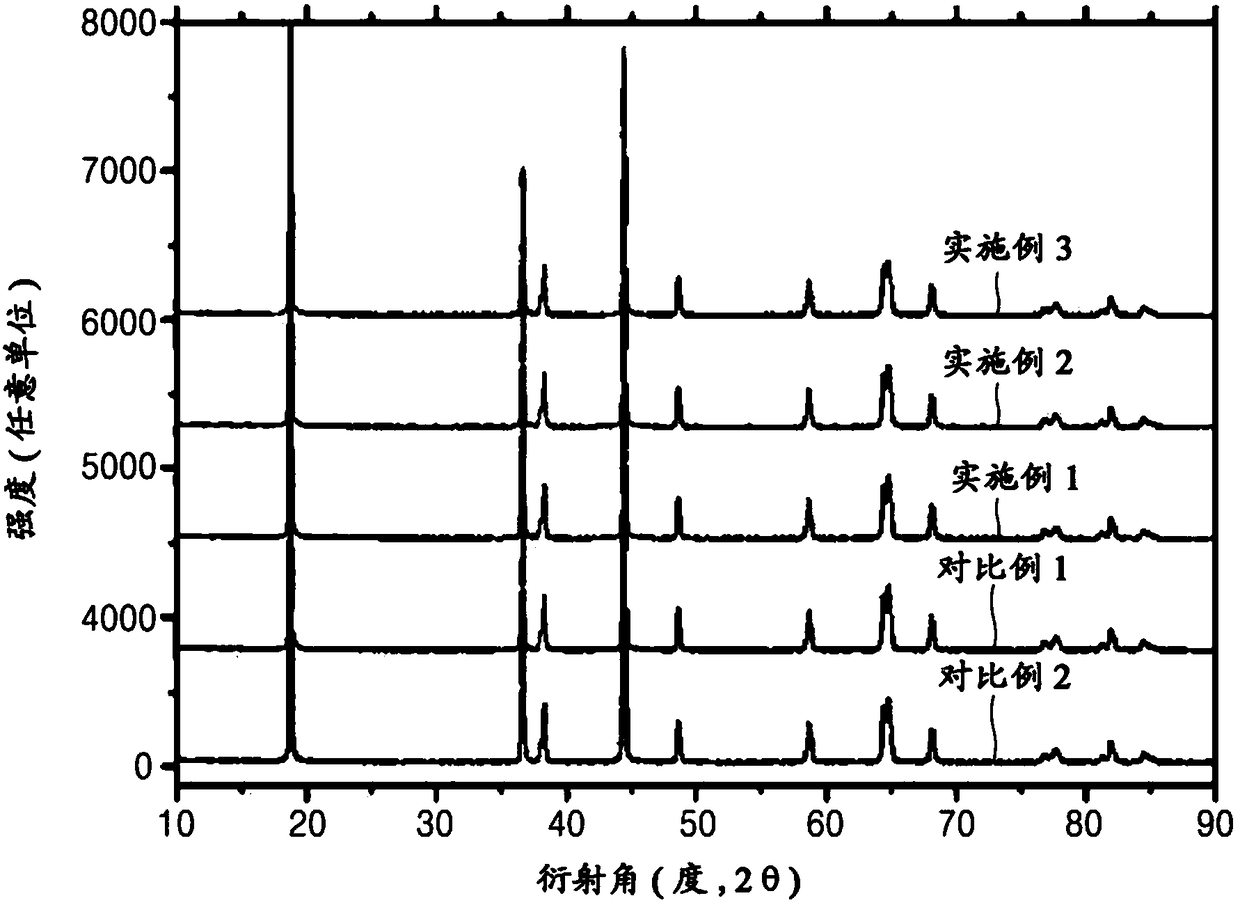

[0141] Example 1: Ni91+LiMnCoO 4 Spinel 0.5% by weight (powder: distilled water = 100:40)

[0142] Prepare 100 parts by weight of Li as the first lithium transition metal oxide 1.03 Ni 0.91 co 0.06 mn 0.03 o 2 powder.

[0143] As a precursor for the second transition metal oxide, 0.5 parts by weight of Co(NO 3 ) 2 ·H 2 O and Mn(NO 3 ) 2 4H 2 Precursor mixture of O. The precursor mixture was added to 40 parts by weight of distilled water, and the resultant was stirred at 80° C. for 1 minute to prepare an aqueous solution.

[0144] The aqueous solution thus prepared was added to 100 parts by weight of Li 1.03 Ni 0.91 co 0.06 mn 0.03 o 2 powder, and the resultant was stirred at 80° C. for 5 minutes to prepare a mixture.

[0145] The mixture was dried in an oven at 120° C. for 12 hours to prepare a dry product.

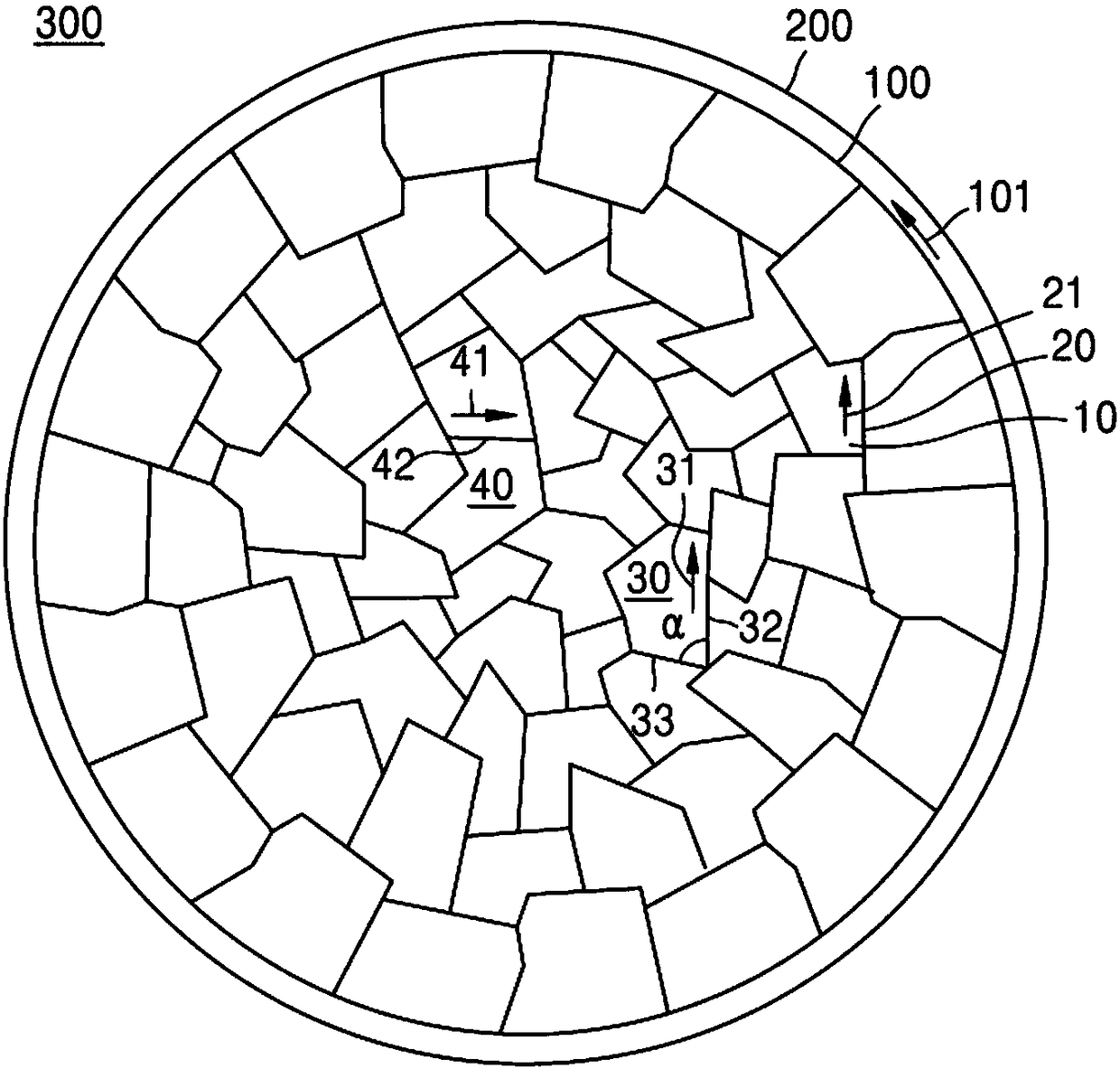

[0146] The dried product was placed in a furnace and heat-treated therein at 720° C. for 5 hours under an oxygen flow to prepare a composite cathode ac...

Embodiment 2

[0148] Example 2: Ni91+LiMnCoO 4 Spinel 1.0% by weight (powder:distilled water=100:40)

[0149] The composite positive electrode active material was prepared in the same manner as in Example 1, except as follows: 1 part by weight of Co(NO 3 ) 2 ·H 2 O and Mn(NO 3 ) 2 4H 2The precursor mixture of O based on 100 parts by weight of Li as the first lithium transition metal oxide 1.03 Ni 0.91 co 0.06 mn 0.03 o 2 powder.

[0150] During the heat treatment process, the Li 1.03 Ni 0.91 co 0.06 mn 0.03 o 2 LiMnCoO having a spinel crystal structure is formed on the surface of the core and in the grain boundary between adjacent primary particles among a plurality of primary particles 4 cladding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap