Brake pad having noise reducing function and preparation method of same

A technology of brake pads and functions, applied in the field of brake pads with noise reduction function and its preparation, can solve the problems of damage to the hearing of drivers and passengers, threats to the safety of drivers and passengers, and easy generation of a large number of sparks, so as to reduce thermal deformation and improve Oxidation resistance and wettability, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

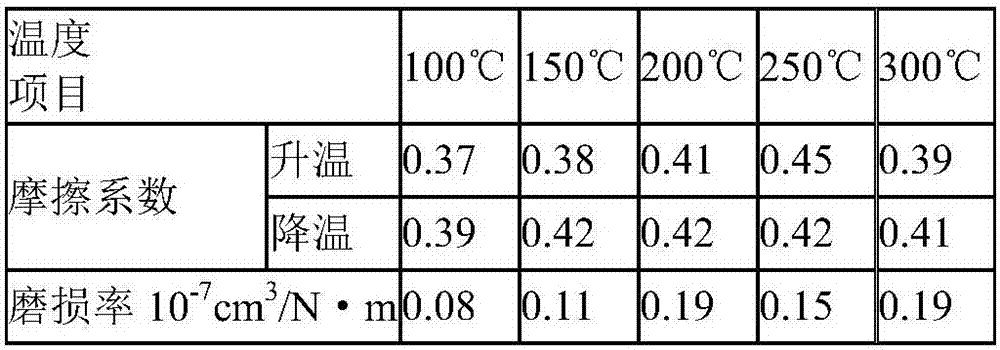

Examples

Embodiment 1

[0038] A brake pad with a noise reduction function, comprising the following raw materials in parts by weight:

[0039] 10 parts of butyl butylbenzene, 10 parts of modified phenolic resin, 10 parts of styrene-butadiene rubber, 15 parts of nitrile rubber, 6 parts of potassium magnesium titanate flake crystal, 6 parts of polypropylene, 20 parts of flake graphite, 10 parts of boron nitride , 2 parts of binder, 2 parts of feldspar powder, 3 parts of zinc oxide, 10 parts of rubber powder, 2 parts of fluorite powder, 1 part of silicon carbide, 4 parts of glass fiber, and 3 parts of carbon fiber.

[0040] Wherein, the modified phenolic resin is processed as follows: heat 120 parts by weight of phenolic resin to 90°C and then mix with 140 parts by weight of alumina particles, stir, keep the temperature and vacuumize, and degas under vacuum for 3 hours, Stop heating, and add 50 parts by weight of curing agent when the temperature drops to 50°C. The curing agent is 2-methylimidazole, mi...

Embodiment 2

[0049] A brake pad with a noise reduction function, comprising the following raw materials in parts by weight:

[0050] 5 parts of butyl styrene, 5 parts of modified phenolic resin, 5 parts of styrene-butadiene rubber, 10 parts of nitrile rubber, 5 parts of potassium magnesium titanate crystal, 3 parts of polypropylene, 15 parts of flake graphite, 6 parts of boron nitride , 1 part of binder, 1 part of feldspar powder, 0.5 parts of zinc oxide, 5 parts of rubber powder, 1 part of fluorite powder, 0.5 part of silicon carbide, 3 parts of glass fiber, and 2 parts of carbon fiber.

[0051] Wherein, the modified phenolic resin is processed as follows: heat 120 parts by weight of phenolic resin to 90°C and then mix with 140 parts by weight of alumina particles, stir, keep the temperature and vacuumize, and degas under vacuum for 3 hours, Stop heating, and add 50 parts by weight of curing agent when the temperature drops to 50°C. The curing agent is 2-methylimidazole, mix well, add 7 p...

Embodiment 3

[0060] A brake pad with a noise reduction function, comprising the following raw materials in parts by weight:

[0061] 8 parts of butyl styrene, 8 parts of modified phenolic resin, 7 parts of styrene-butadiene rubber, 12 parts of nitrile rubber, 5 parts of potassium magnesium titanate crystal, 4 parts of polypropylene, 16 parts of flake graphite, 8 parts of boron nitride , 1 part of binder, 2 parts of feldspar powder, 2 parts of zinc oxide, 9 parts of rubber powder, 1 part of fluorite powder, 0.5 part of silicon carbide, 3 parts of glass fiber, and 2 parts of carbon fiber.

[0062] Wherein, the modified phenolic resin is processed as follows: heat 120 parts by weight of phenolic resin to 90°C and then mix with 140 parts by weight of alumina particles, stir, keep the temperature and vacuumize, and degas under vacuum for 3 hours, Stop heating, and add 50 parts by weight of curing agent when the temperature drops to 50°C. The curing agent is 2-methylimidazole, mix well, add 7 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com