DC brush motor drive controller for electric mechanism

A technology of DC brush motor and drive controller, applied in the direction of DC motor rotation control, etc., can solve the problems of large size of H-bridge module, complicated principle, limited use of H-bridge module, etc., achieving a small number of chips, simple logic judgment, Design flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

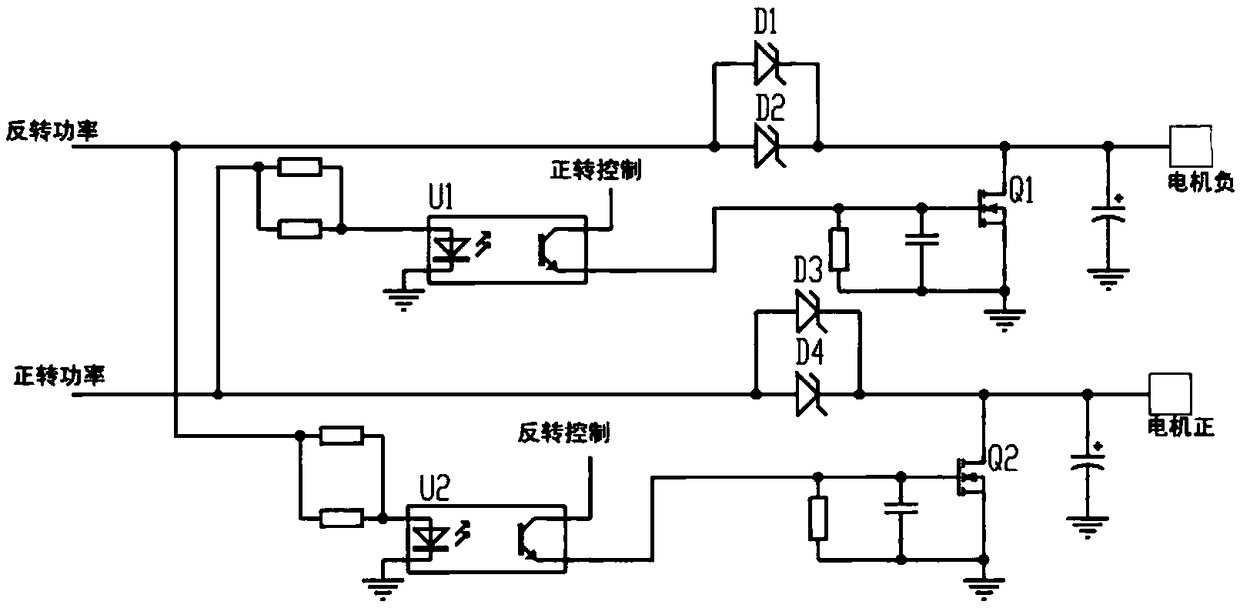

[0021] The design idea of the present invention is: the original H-bridge circuit needs to control the four-way power device switch through two-way logic signals, so as to form a forward drive loop and a reverse drive loop on the DC brushed motor, that is, to complete the DC brushed motor. Forward and reverse. In principle, the brushed DC motor current has only two power current flow directions, so it only needs to be able to control the two currents to complete the forward and reverse rotation of the brushed DC motor. Therefore, the power devices can be reduced to two circuits, and the corresponding logic signals only need two circuits. Designing with this idea can reduce the volume in principle.

[0022] See the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com