a microphone

A microphone and diaphragm technology, applied in the field of measurement, can solve the problems of unfavorable air circulation, reduce the mechanical sensitivity of the diaphragm, limit the high signal-to-noise ratio performance of the microphone, etc., and achieve the effect of high sensitivity and guaranteed performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

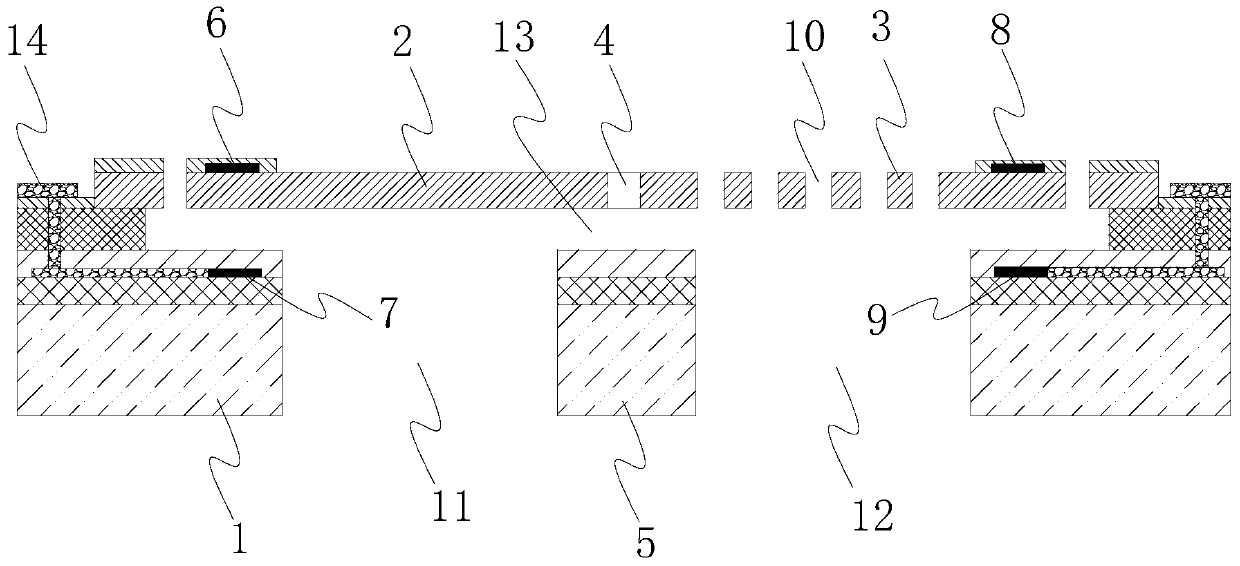

Embodiment 1

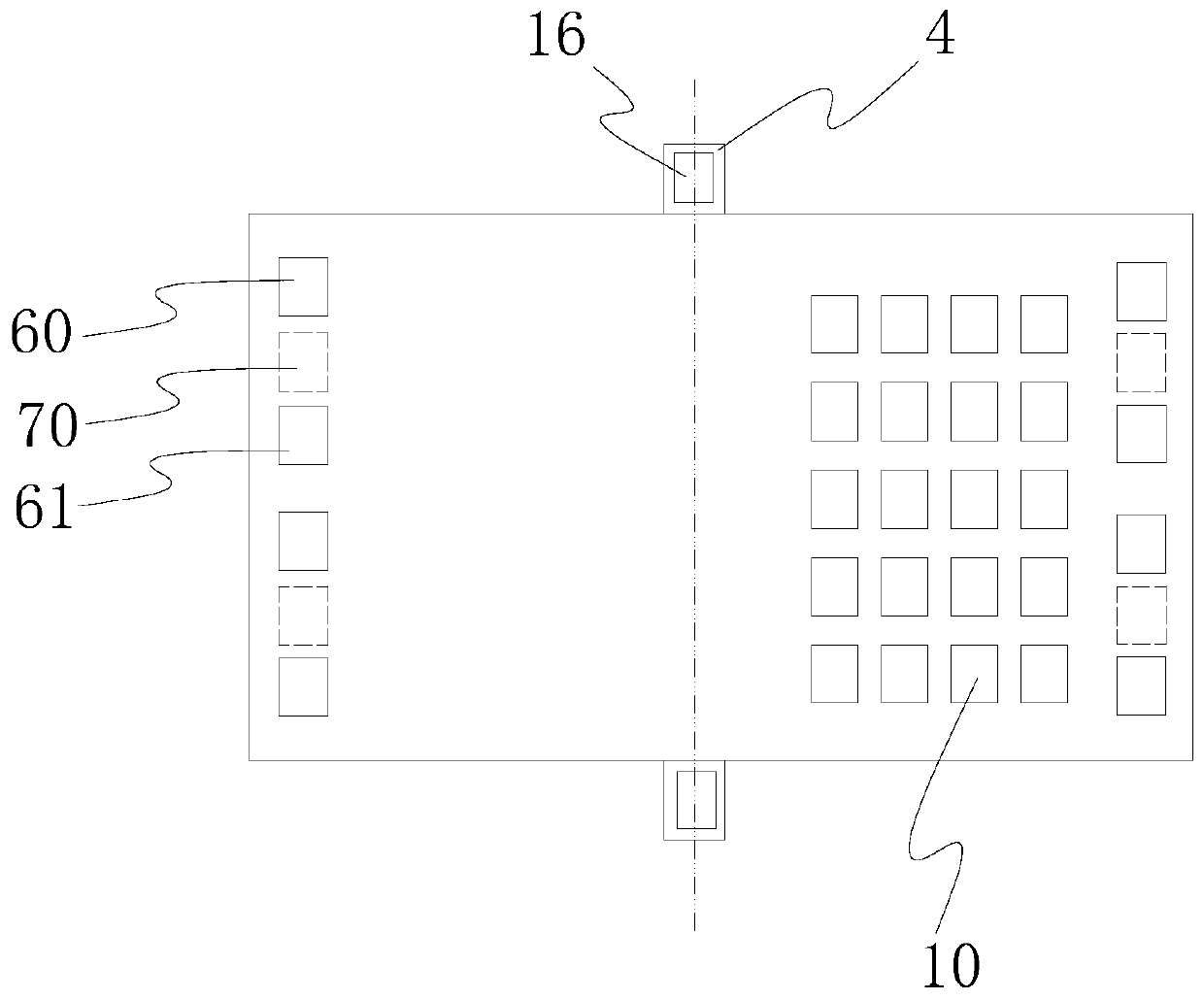

[0069] Specifically, refer to figure 2 , the first magnet 60 and the second magnet 61 are arranged on the first side 2 position of the diaphragm, the first magnet 60 and the second magnet 61 can adopt magnetic thin films, and the magnetic thin films can directly adopt magnetic materials, and can also be formed after forming the thin films. The film is magnetized. In a specific embodiment of the present invention, the magnetic thin film may be made of CoCrPt or CoPt.

[0070] The first magnet 60 and the second magnet 61 can be formed on the first side 2 of the diaphragm by deposition or other means known to those skilled in the art. The first magnet 60 and the second magnet 61 can also be protected by an insulating layer and a passivation layer, which will not be described in detail here.

[0071] The first magnet 60 and the second magnet 61 are arranged adjacent to each other, and are arranged horizontally on the first side 2 of the diaphragm sequentially in such a manner t...

Embodiment 2

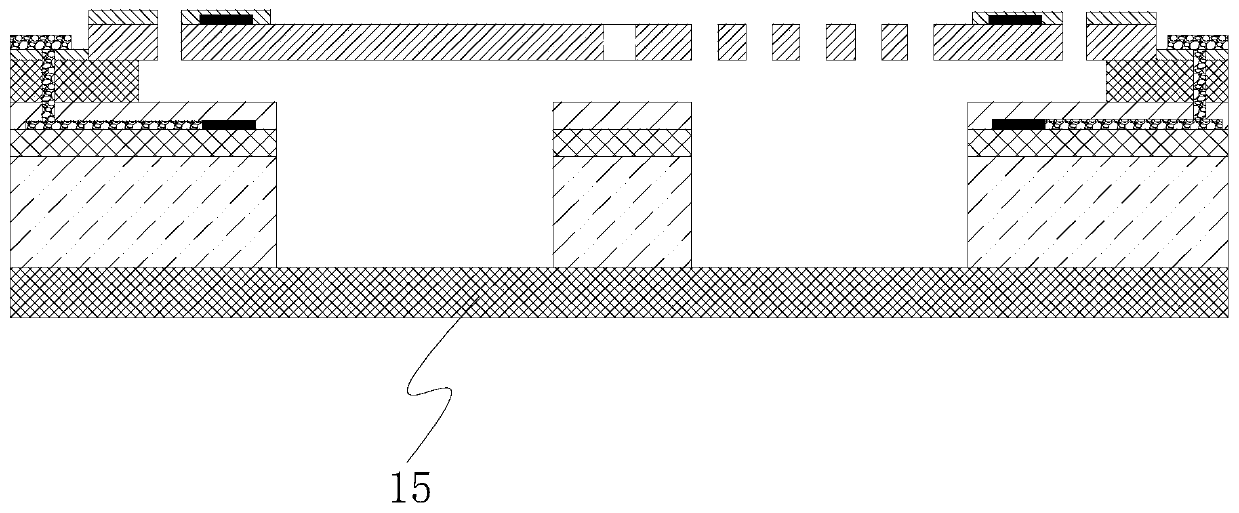

[0080] In a specific embodiment of the present invention, a bearing part 15 is also provided above the diaphragm, refer to Figure 5 . The carrying part 15 may be directly or indirectly connected to the substrate 1 through a spacer, and there is a certain gap between the carrying part 15 and the diaphragm, so that the carrying part 15 will not hinder the deflection of the diaphragm.

[0081] refer to Figure 5 , the first magnet 63 and the second magnet 62 of the first detection structure are respectively disposed on the substrate 1 and the bearing part 15 . The first magnet 63 and the second magnet 62 can use magnetic thin films, and the magnetic thin films can be directly made of magnetic materials, or the thin films can be magnetized after forming the thin films. In a specific embodiment of the present invention, the magnetic thin film may be made of CoCrPt or CoPt. In order to protect the magnets, the first magnet 63 and the second magnet 62 may respectively be provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com