Intermediate casing of a turbine engine with seals at the arm/shroud interface

A technology for turbine engines and intermediate casings, which is applied in the direction of machines/engines, engine components, gas turbine devices, etc., and can solve problems such as instability, increasing the shield gap between the arm and the intermediate casing, and affecting component performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

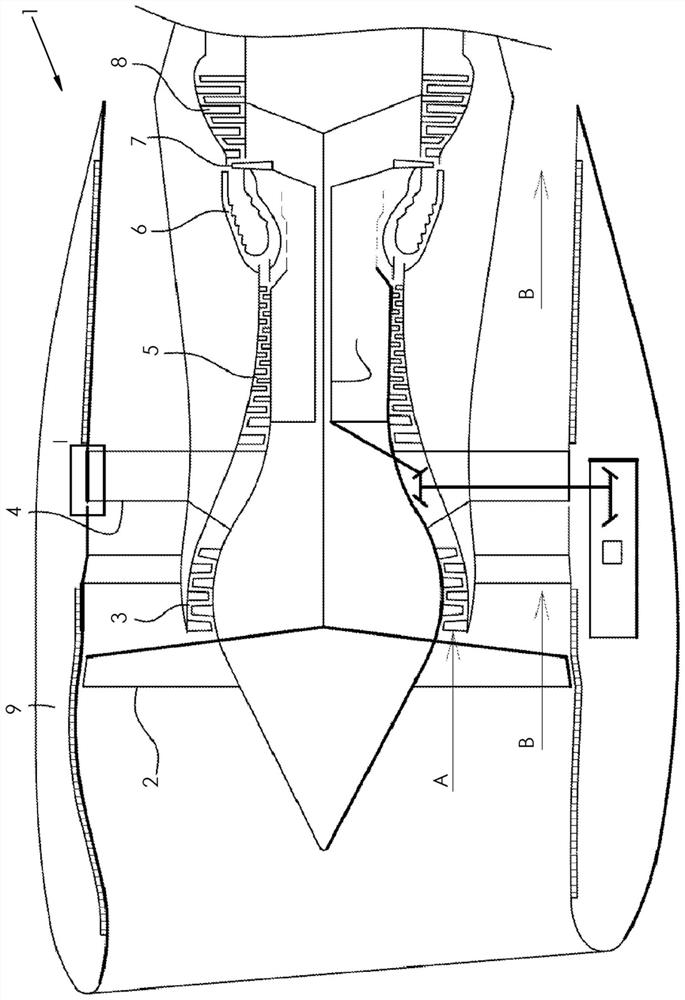

[0043] figure 1 A turbofan engine 1 is schematically shown. In this figure a circular relief I is shown, which is located in the area of interest in which the invention is applied. In downstream direction, the turbine engine 1 comprises a blower 2 , a low-pressure compressor 3 , an intermediate casing 4 , a high-pressure compressor 5 , a combustion chamber 6 , a high-pressure turbine 7 and a low-pressure turbine 8 .

[0044] The turbine engine 1 also includes a nacelle 9 . The air entering the turbine engine 1 is divided into a primary air flow (arrow A) and a secondary air flow (arrow B); the primary air flow is inside the low pressure compressor 3 and high pressure compressor 5 towards the combustion chamber 6 and then passes through the high pressure turbine 7 and The low pressure turbine 8 circulates; the secondary air flow bypasses the compressor 3 , the combustor 6 and the turbine 7 .

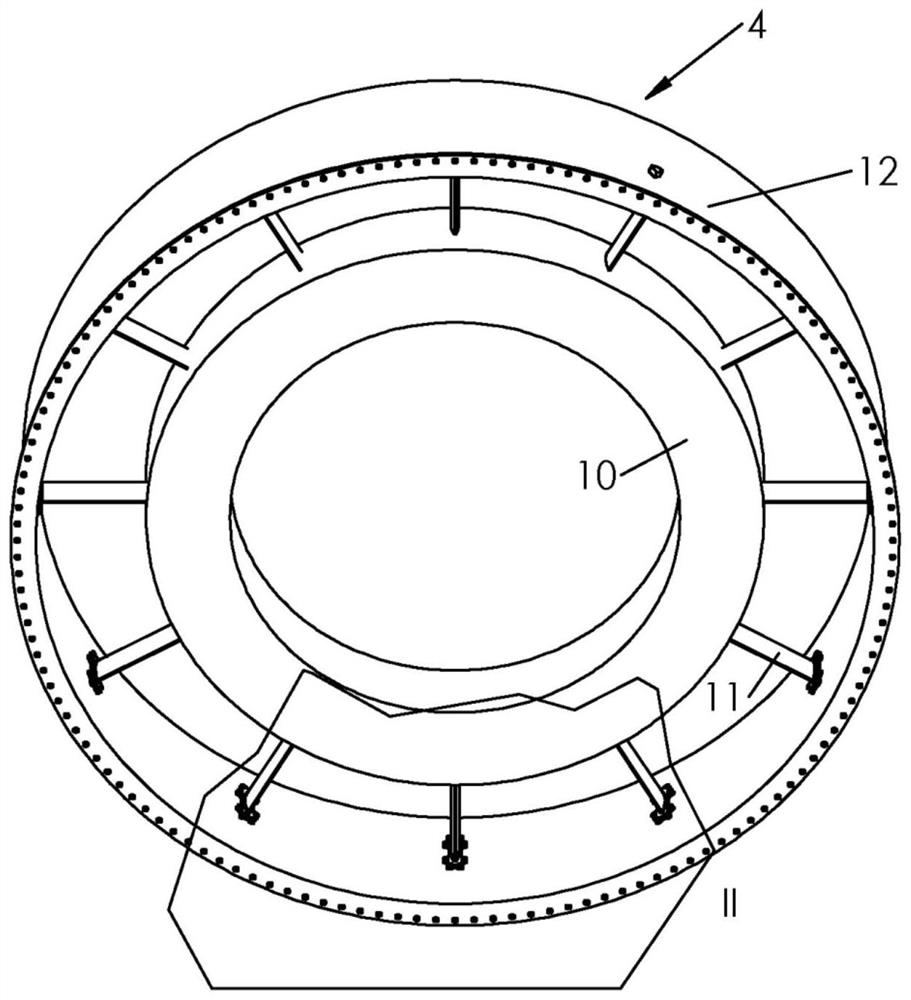

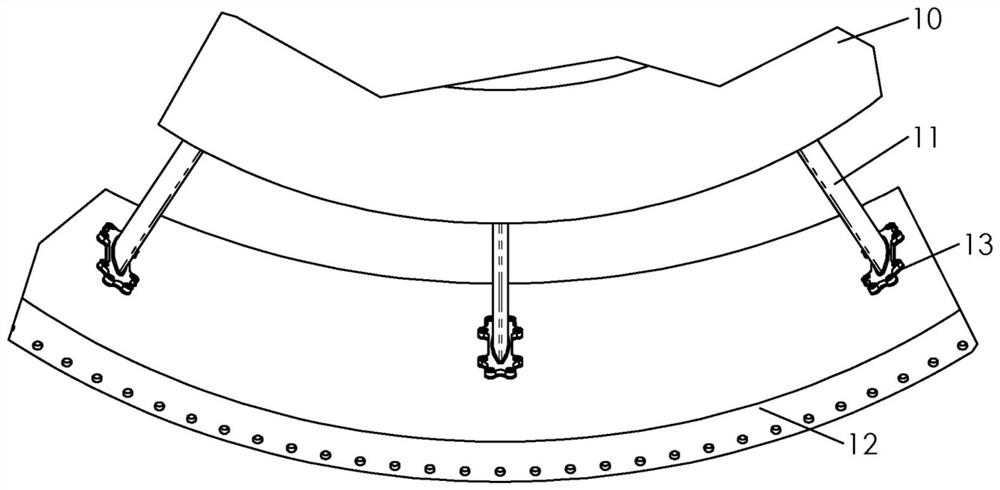

[0045] figure 2 is a simplified schematic diagram of an intermediate casing 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com