High-pressure accumulator and method for producing a high-pressure accumulator

A storage and high-pressure technology, applied to fuel injection devices with oil storage, machines/engines, engine components, etc., can solve problems such as reducing component life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

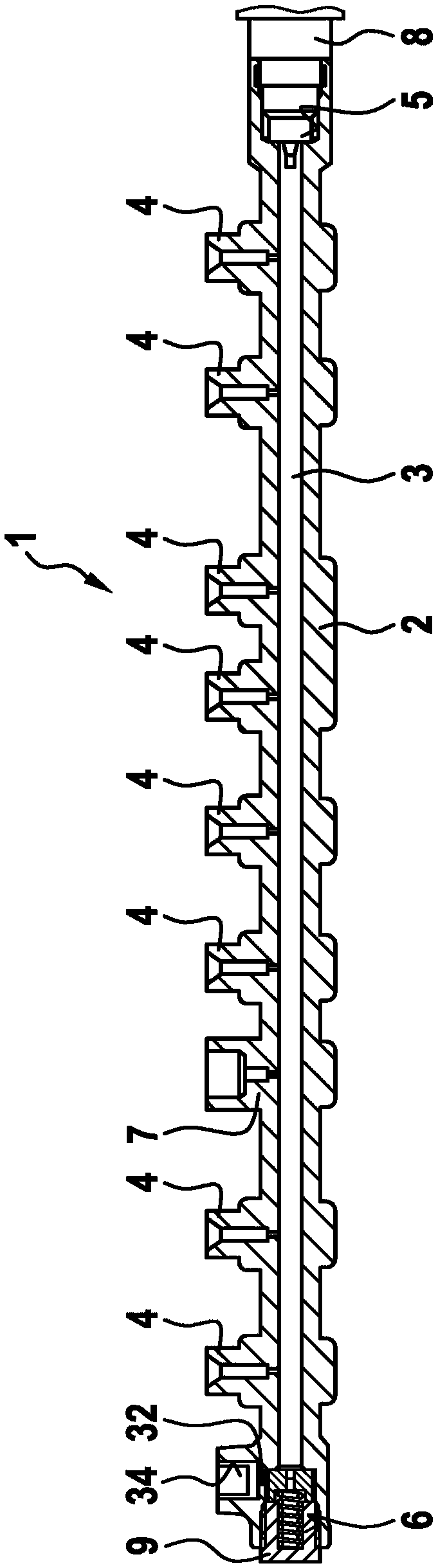

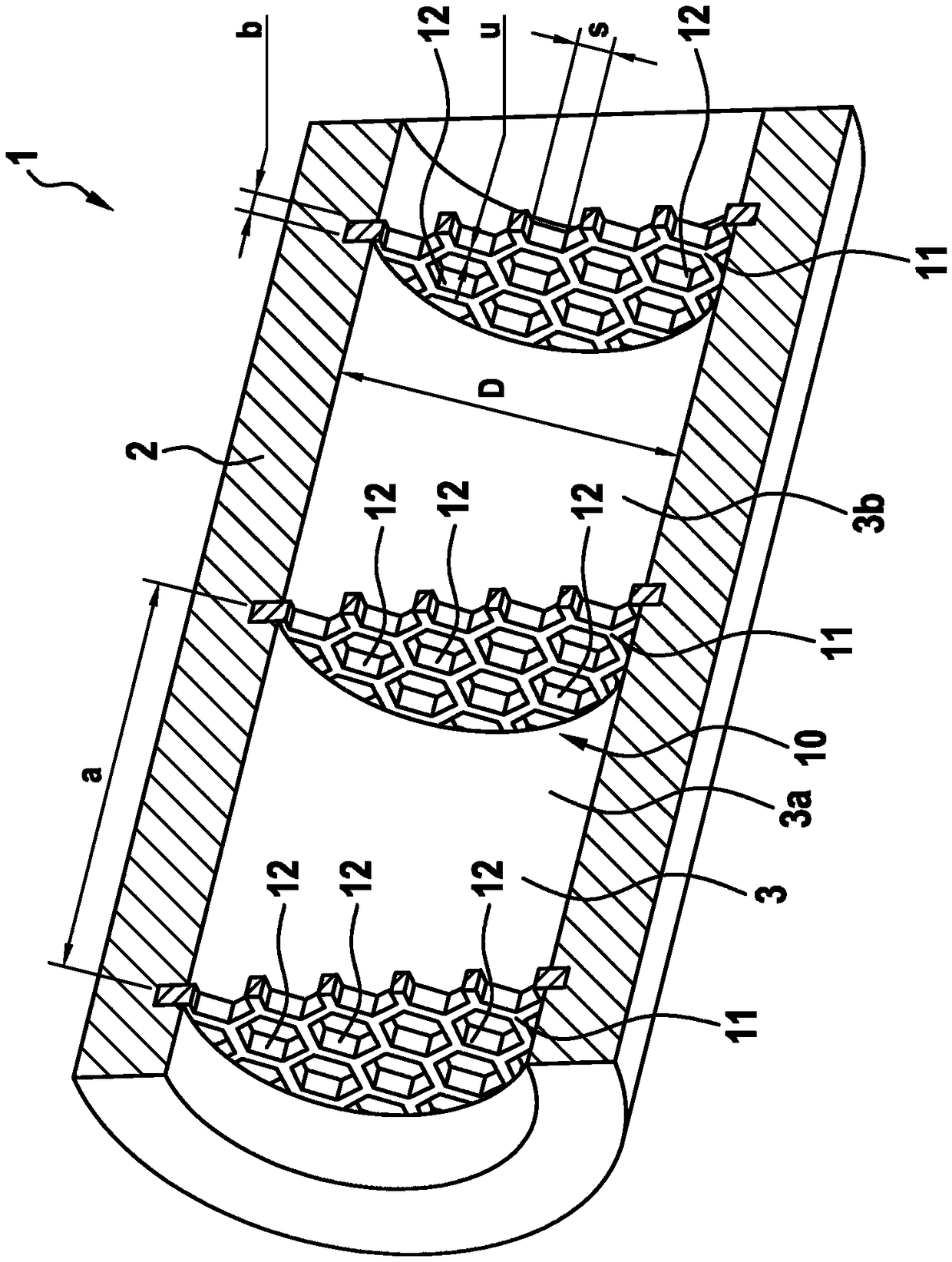

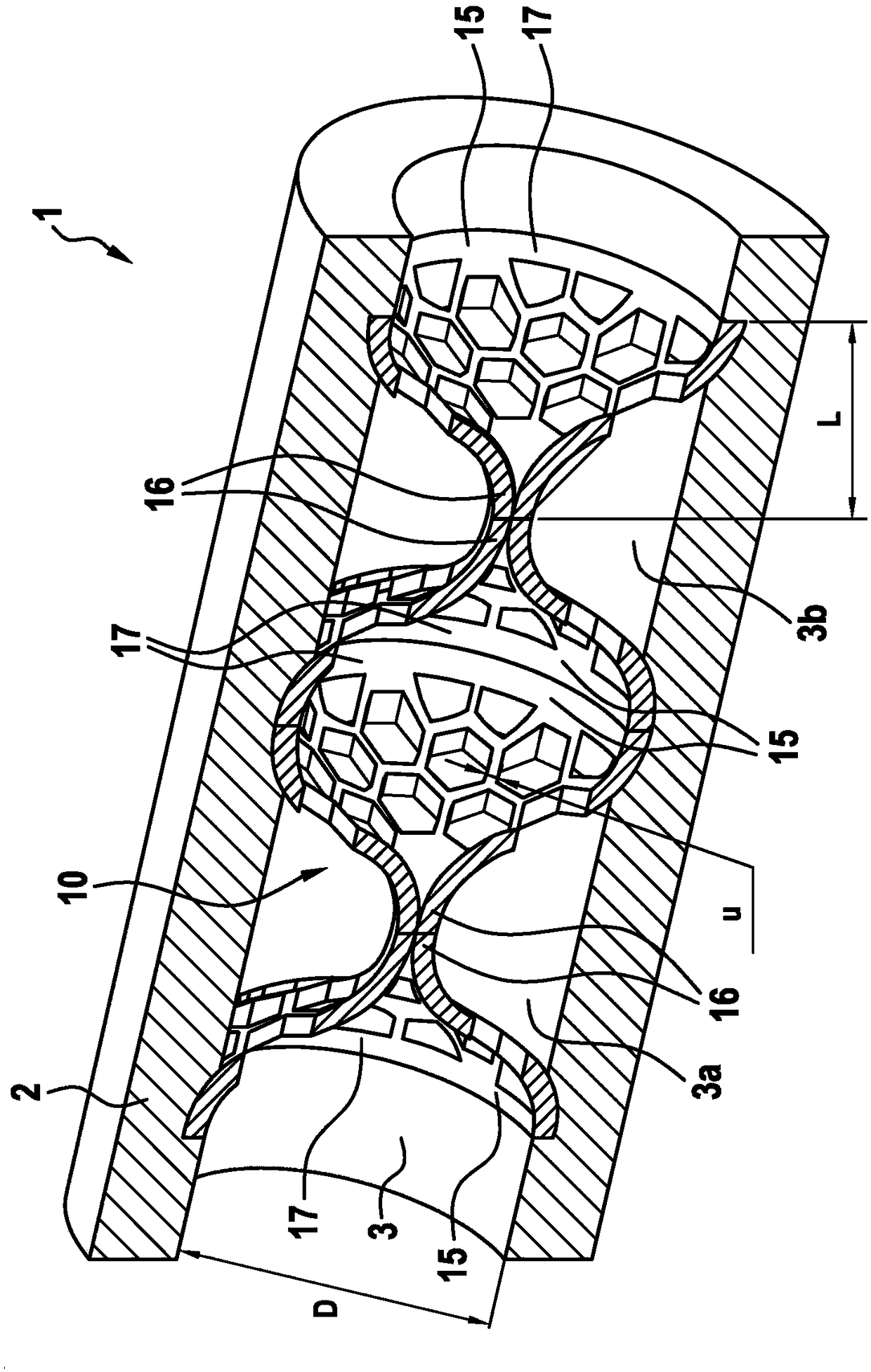

[0023] exist figure 1 In the longitudinal section of , a tubular high-pressure accumulator as known from the prior art is marked with 1 . The high-voltage store 1 has a store tube 2 which surrounds a store space 3 . The high-pressure accumulator 1 is provided for the injection system of the internal combustion engine and is usually referred to as a rail.

[0024] A plurality of outlet connections 4 for fuel pressure lines (not shown) to the injectors are formed on the accumulator line 2 of the high-pressure accumulator 1 . An inlet connection 7 to a high-pressure pump (not shown) is also formed on the accumulator tube 2 . In addition, receptacles 5 and 6 for attachment parts 8 and 9 are formed on the storage tube 2 . The attachment part 8 is usually a rail pressure sensor for ascertaining the pressure in the storage space 3 . The attachment part 9 is a pressure valve, preferably a pressure regulating valve for regulating the pressure in the storage space 3 . The pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com