High-voltage electric field low-temperature plasma cold sterilization method for packaged betel nuts

A technology of low-temperature plasma and high-voltage electric field, applied in food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of roughness and unevenness, unsuitable sterilization of betel nut processed products, etc., and achieve short processing time and high-efficiency green cold sterilization Technology, the effect of shortening the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

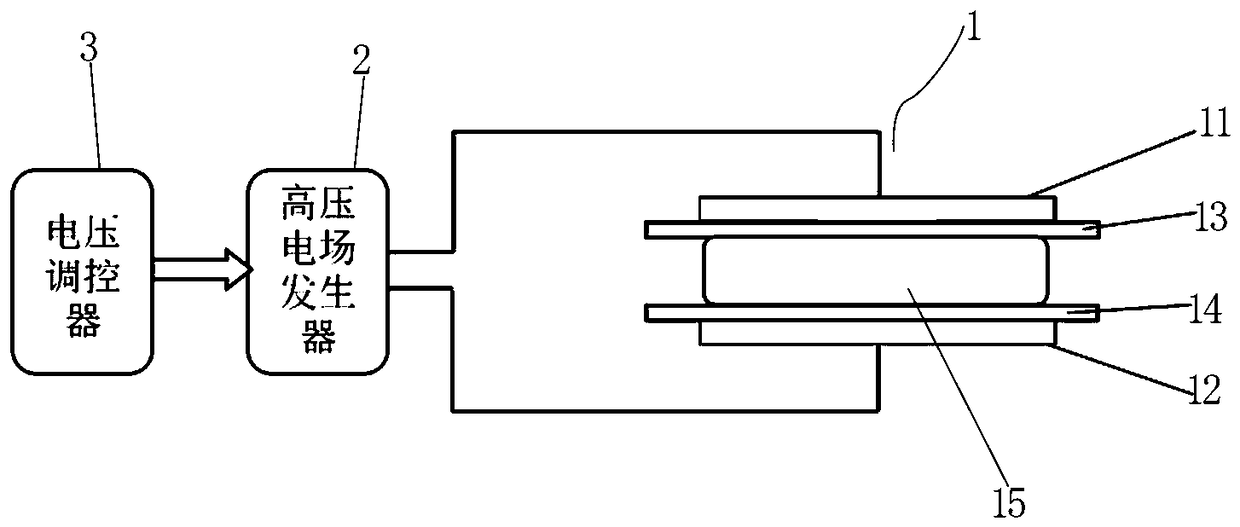

Method used

Image

Examples

Embodiment 1

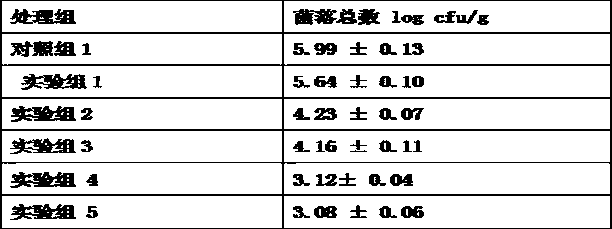

[0029] Low-temperature plasma cold sterilization treatment for bagged betel nut products.

[0030] Blank group 1: The packaged samples were directly detected for the total number of colonies without plasma treatment;

[0031] Experimental group 1: The packaged samples were treated with a voltage intensity of 17.8 kV / cm for 30 seconds at a time, and the total number of colonies was detected.

[0032] Experimental group 2: The packaged samples were treated at a voltage of 17.8 kV / cm for 30 seconds at a time, with an interval of 60 seconds.

[0033] Repeat 3 times to detect the total number of colonies.

[0034] Experimental group 3: The packaged samples were subjected to a voltage intensity of 17.8 kV / cm, treated for 30 seconds at a time, with an interval of 60 seconds,

[0035] Repeat 5 times to detect the total number of colonies.

[0036] Experimental group 4: The packaged samples were treated with a voltage intensity of 17.8 kV / cm for 30 seconds at a time, with an interva...

Embodiment 2

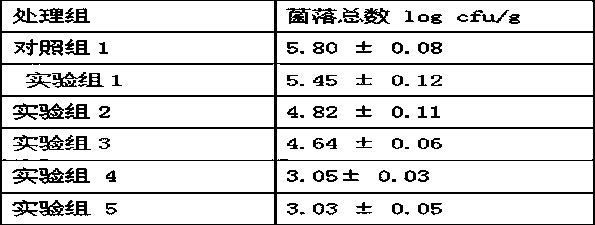

[0044] Low-temperature plasma cold sterilization treatment for boxed betel nut products.

[0045] Blank group 1: The packaged samples were directly detected for the total number of colonies without plasma treatment;

[0046] Experimental group 1: The packaged samples were treated at a voltage of 21.8 kV / cm for 30 seconds at a time, and the total number of colonies was detected.

[0047] Experimental group 2: The packaged samples were subjected to a voltage intensity of 21.8 kV / cm, treated for 30 seconds at a time, with an interval of 60 seconds,

[0048] Repeat 3 times to detect the total number of colonies.

[0049] Experimental group 3: The packaged samples were subjected to a voltage intensity of 21.8 kV / cm, treated for 30 seconds at a time, with an interval of 60 seconds,

[0050] Repeat 5 times to detect the total number of colonies.

[0051] Experimental group 4: The packaged samples were subjected to a voltage intensity of 21.8 kV / cm, treated for 30 seconds at a time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com