Tert-butoxy ethyl dithiocarbonate and preparation method and application thereof

A technology of tert-butoxyethyl dithiocarbonate and tert-butoxyethanol, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, feeding devices, etc. Sexual odor, environmental pollution of xanthate production plants and concentrators, etc., to achieve the effects of fast mixing, low production cost, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Add 31.05 parts of 2-tert-butoxyethanol and 15.50 parts of carbon disulfide into the reactor, divide it into 3 times under stirring, respectively add 3 parts, 3 parts, and 2.14 parts of granular sodium hydroxide into the reactor, add each time Stir for 10 to 20 minutes after completion, and control the reaction temperature during alkali addition to be lower than 35°C. After adding caustic alkali, stir and react at 30°C for 5 hours to obtain a yellow paste solid, which turns into a yellow block solid when cooled to room temperature. That is, the target collector product.

[0081] After analysis and detection, the collector product tert-butoxyethyl sodium dithiocarbonate has a content of 76.39%, and the yield of tert-butoxyethyl sodium dithiocarbonate based on sodium hydroxide is 96.26%.

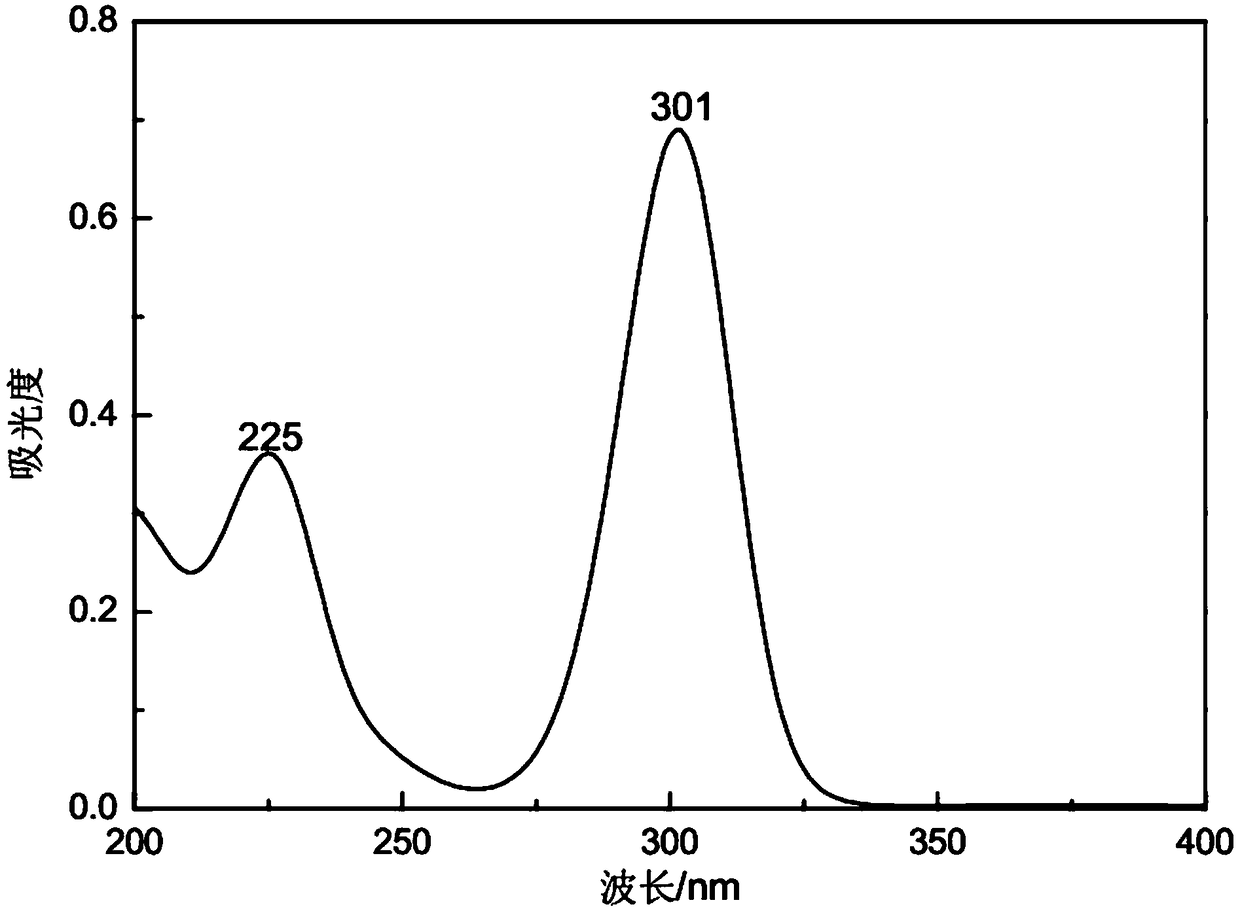

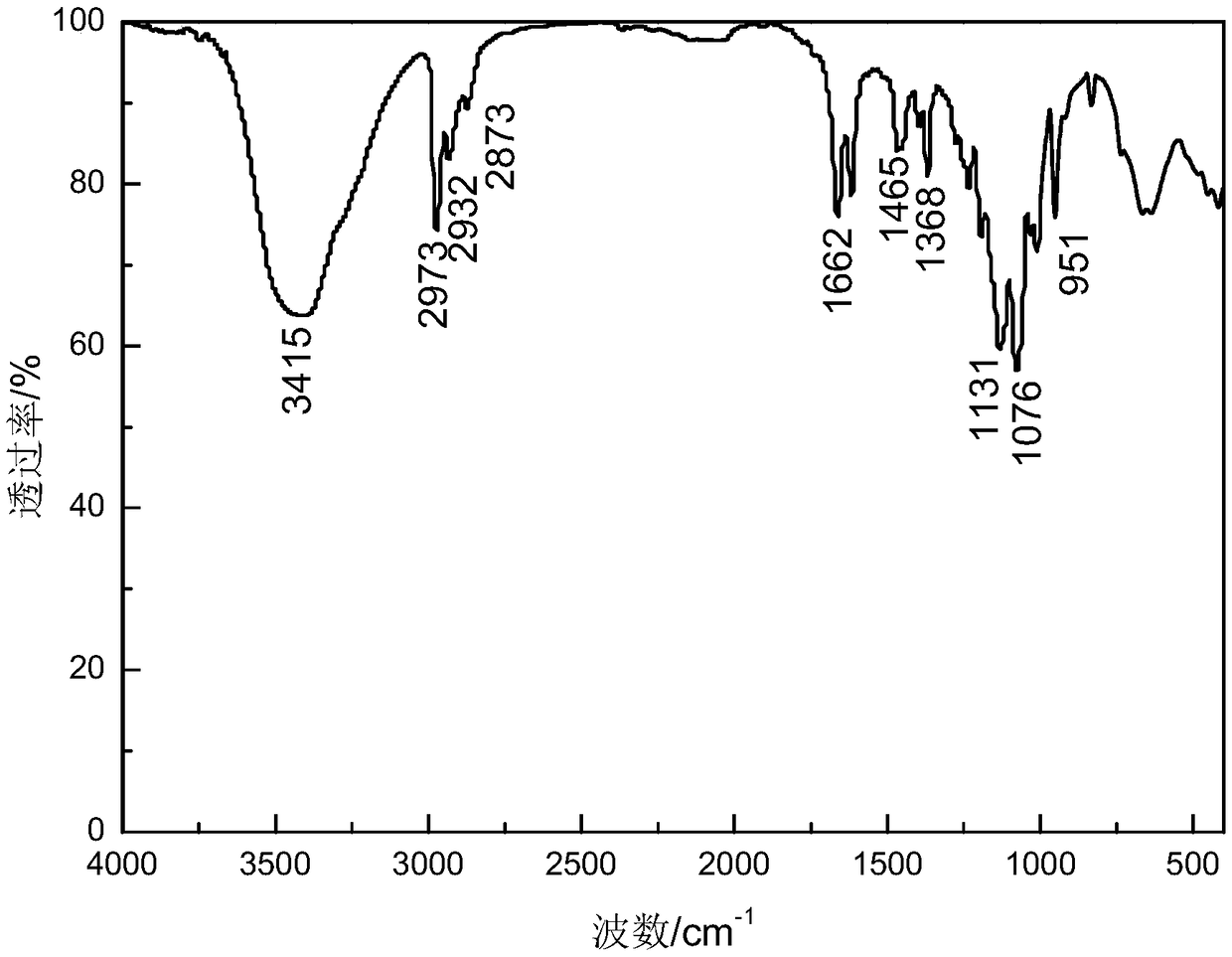

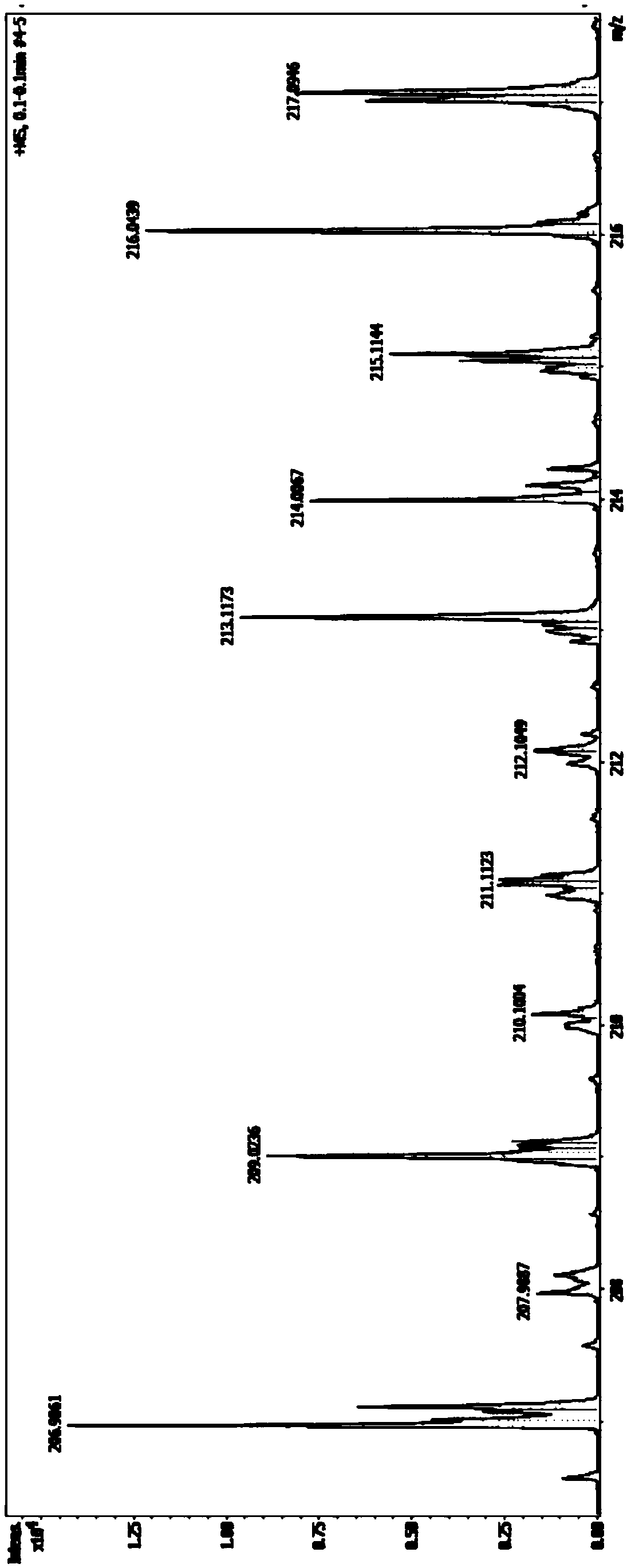

[0082] The product is characterized after separation and purification by recrystallization, and the ultraviolet spectrum of tert-butoxyethyl sodium dithiocarbonate is as follows: figur...

Embodiment 2

[0091] Add 31.05 parts of 2-tert-butoxyethanol (containing 2-tert-butoxyethanol 92%, ethylene glycol 2%, 1,2-dibutoxyethane 6%) and 8.14 parts of granular sodium hydroxide to In the reactor, add 15.50 parts of carbon disulfide dropwise under stirring at 15-30°C. After the dropwise addition, keep the reaction temperature at 30°C, stir for 4 hours, and the reaction ends. A yellow paste solid is obtained, which turns into a yellow block solid when cooled to room temperature, which is the target collector product. After analysis and detection, the collector product tert-butoxyethyl sodium dithiocarbonate has a content of 75.79%, and the yield of sodium tert-butoxyethyl dithiocarbonate based on sodium hydroxide is 95.88%.

Embodiment 3

[0093]31.03 parts of 2-tert-butoxyethanol and 15.52 parts of carbon disulfide were added to the reactor, and they were divided into 3 times under stirring. In the container, stir for 10 to 20 minutes after each addition, and control the reaction temperature during alkali addition to be lower than 35°C. After adding caustic alkali, stir and react at 30°C for 3 hours to obtain a yellow paste solid, which is cooled to room temperature. It is a yellow blocky solid, which is the target collector product. After analysis and detection, the content of the collector product tert-butoxyethyl potassium dithiocarbonate is 79.14%, and the yield of tert-butoxyethyl potassium dithiocarbonate based on potassium hydroxide is 97.02%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap