Electric riveting machine for bearing retainer

A technology of bearing cage and riveting machine, which is applied in the field of mechanical processing, can solve the problems of different sizes of rivet heads, poor consistency, and insufficient riveting, so as to improve production efficiency, solve poor consistency, and ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

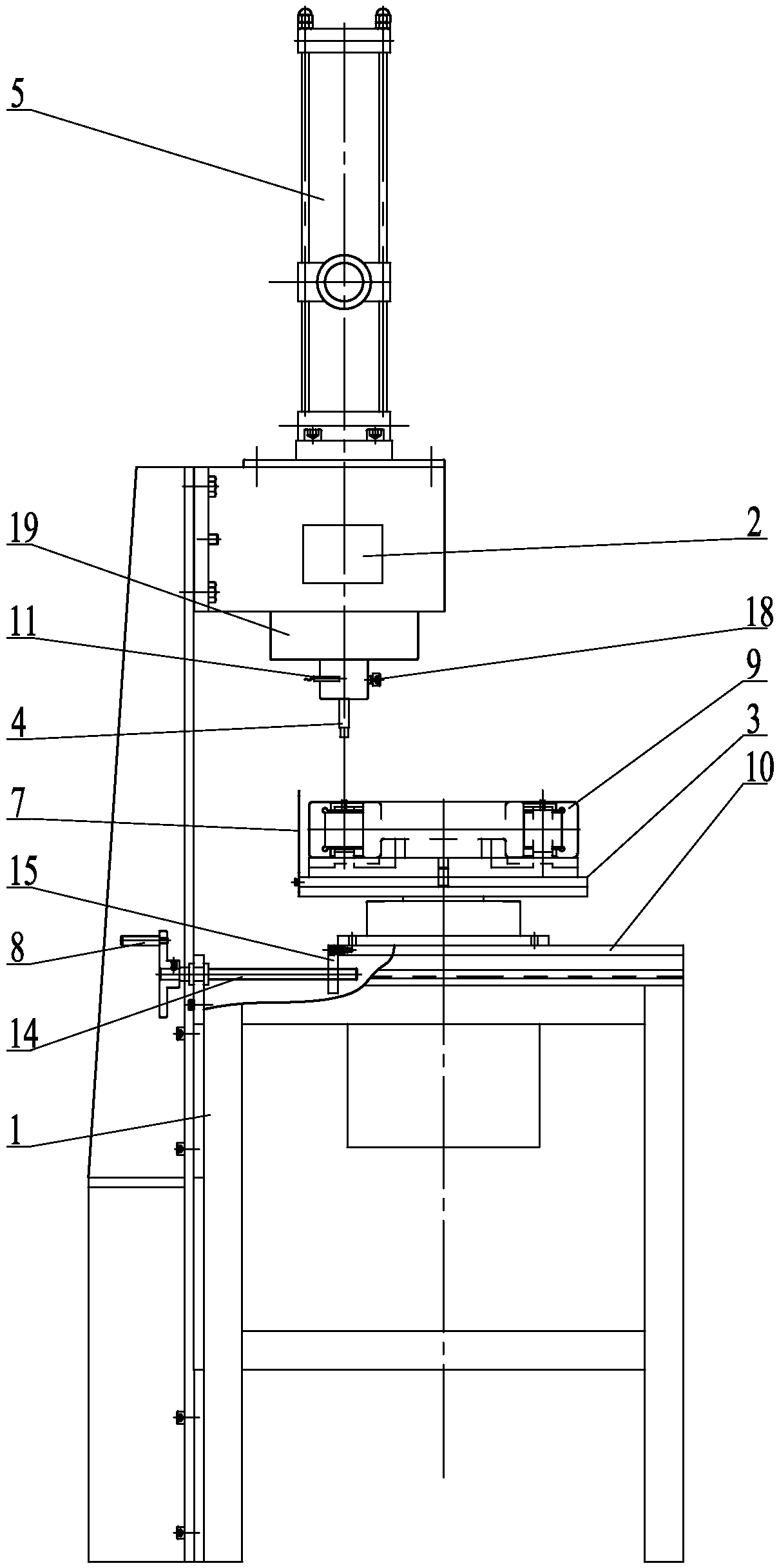

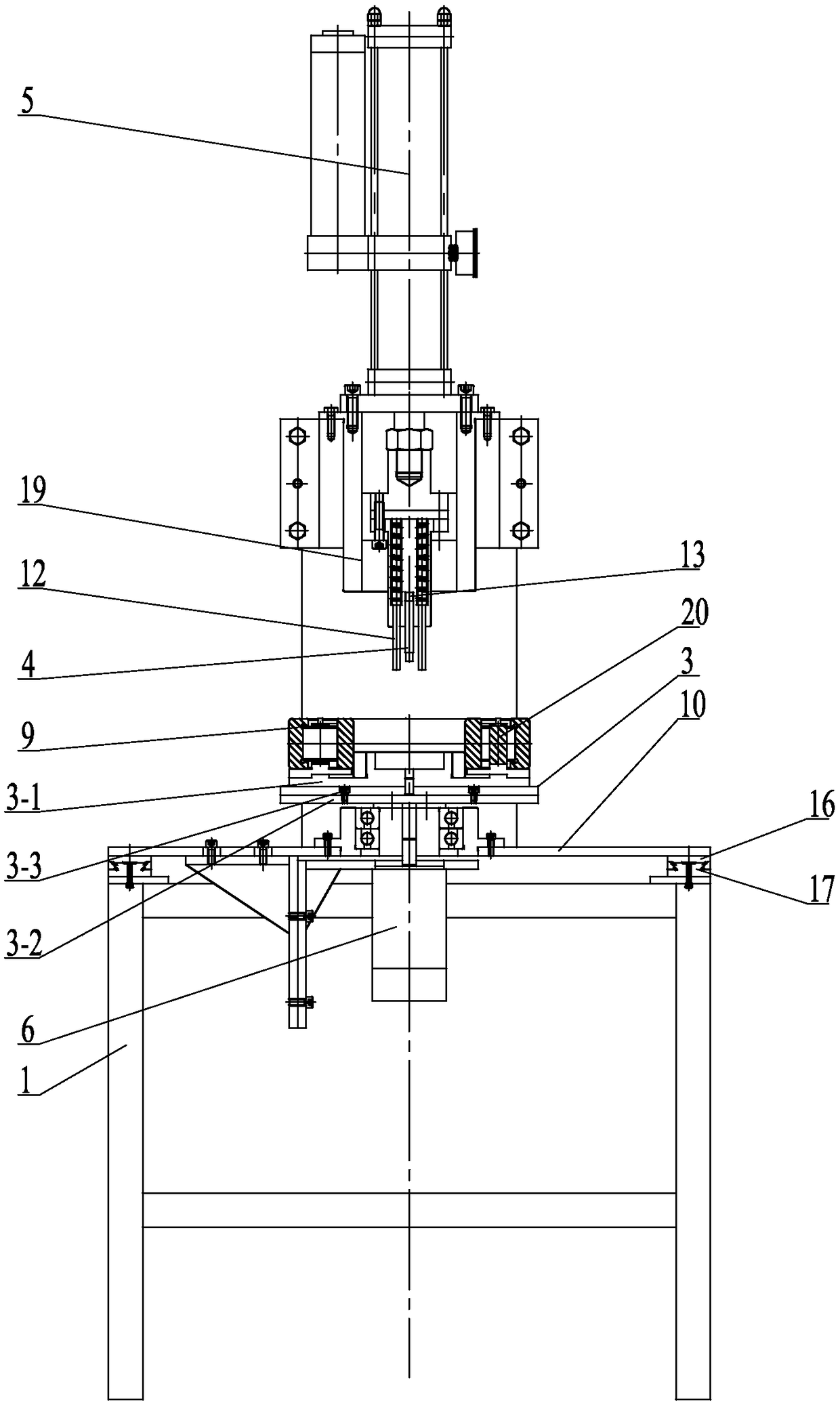

[0010] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment, a bearing cage electric riveting machine described in this embodiment includes a frame 1, a controller 2, a bearing fixing seat 3, a riveting punch 4, a cylinder 5, a servo motor 6, a base 10, a heating 11 and a horizontal movement mechanism, the cylinder 5 is vertically arranged on the upper end of the frame 1, the riveting punch 4 is arranged at the end of the piston rod of the cylinder 5, the riveting punch 4 is provided with a heater 11, and the middle part of the frame 2 A base 10 is arranged horizontally, and the base 10 moves horizontally on the frame 2 through a horizontal moving mechanism. The upper end surface of the base 10 is provided with a bearing fixing seat 3, and the bearing fixing seat 3 is arranged at the lower end of the riveting punch 4, and the bearing The middle part of the fixed seat 3 is vertically fixed to the output shaft of the servo motor 6, and the cyl...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 1 to Figure 2 The present embodiment is described. The pointer plate 7 is fixedly connected to one side of the bearing fixing seat 3 in the present embodiment. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0016] The position of the pointer plate 7 designed in this way is the initial position when the servo motor 6 rotates. When placing the bearing 9 to be riveted, the first point to be riveted is directly facing the pointer plate 7, so as to successfully complete the subsequent riveting process.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 2 To illustrate this embodiment, a proximity switch sensor 12 is respectively provided on both sides of the riveting punch 4 in this embodiment, and the proximity switch sensor 12 is connected to the controller 2 . The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0018] Design in this way to realize the upward and downward control of the cylinder 5 piston rod by the proximity switch sensor 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com