Hoisting type 3D (Three Dimensional) compatible automatic film sticking machine

A lifting type, film laminating machine technology, applied in the coating and other directions, can solve the problems of difficult cleaning, accumulated strain on the spring, unable to guarantee the quality of the film collapse, to ensure the quality of the film collapse, easy to clean the dregs, easy to correct the film material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing:

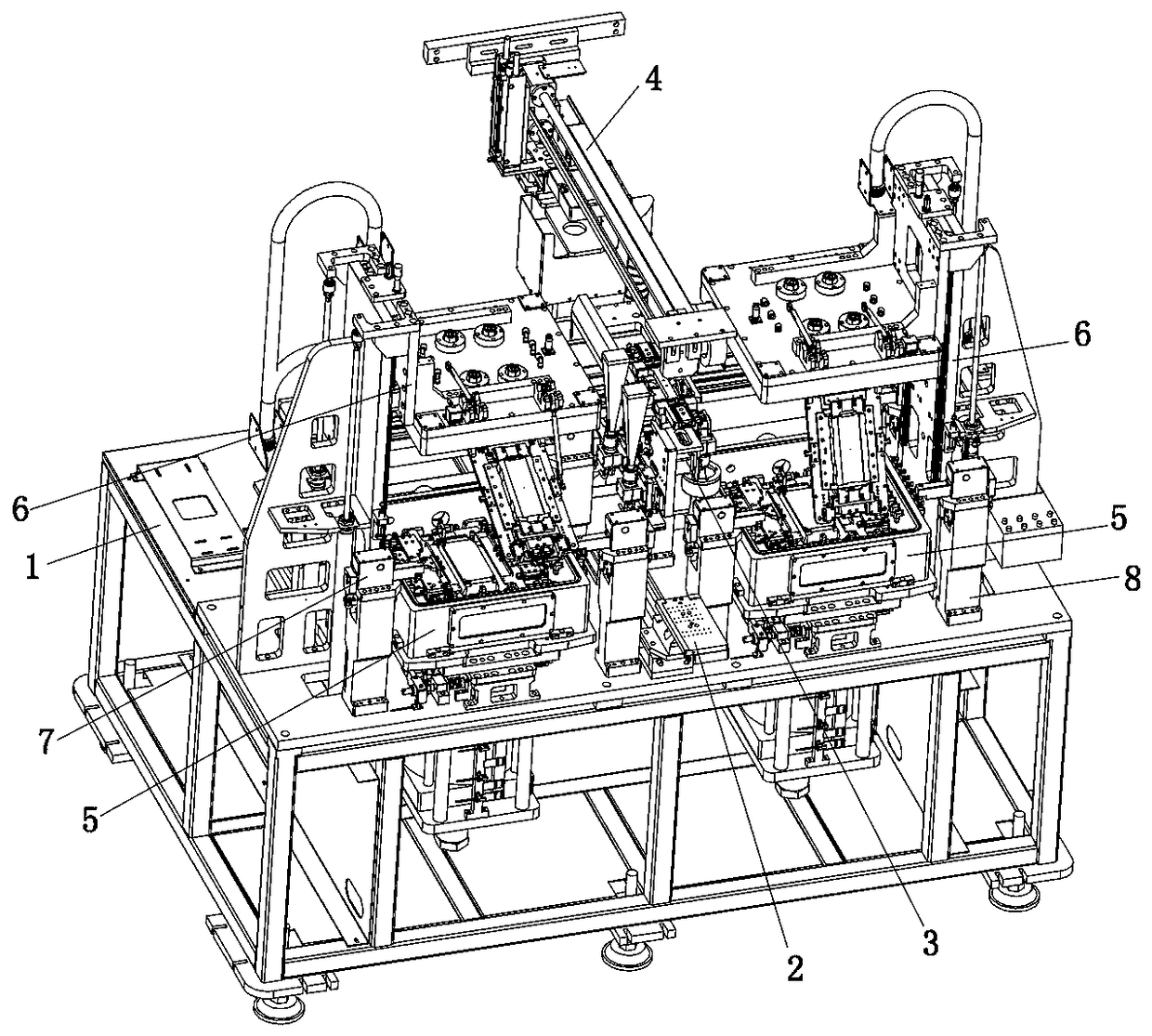

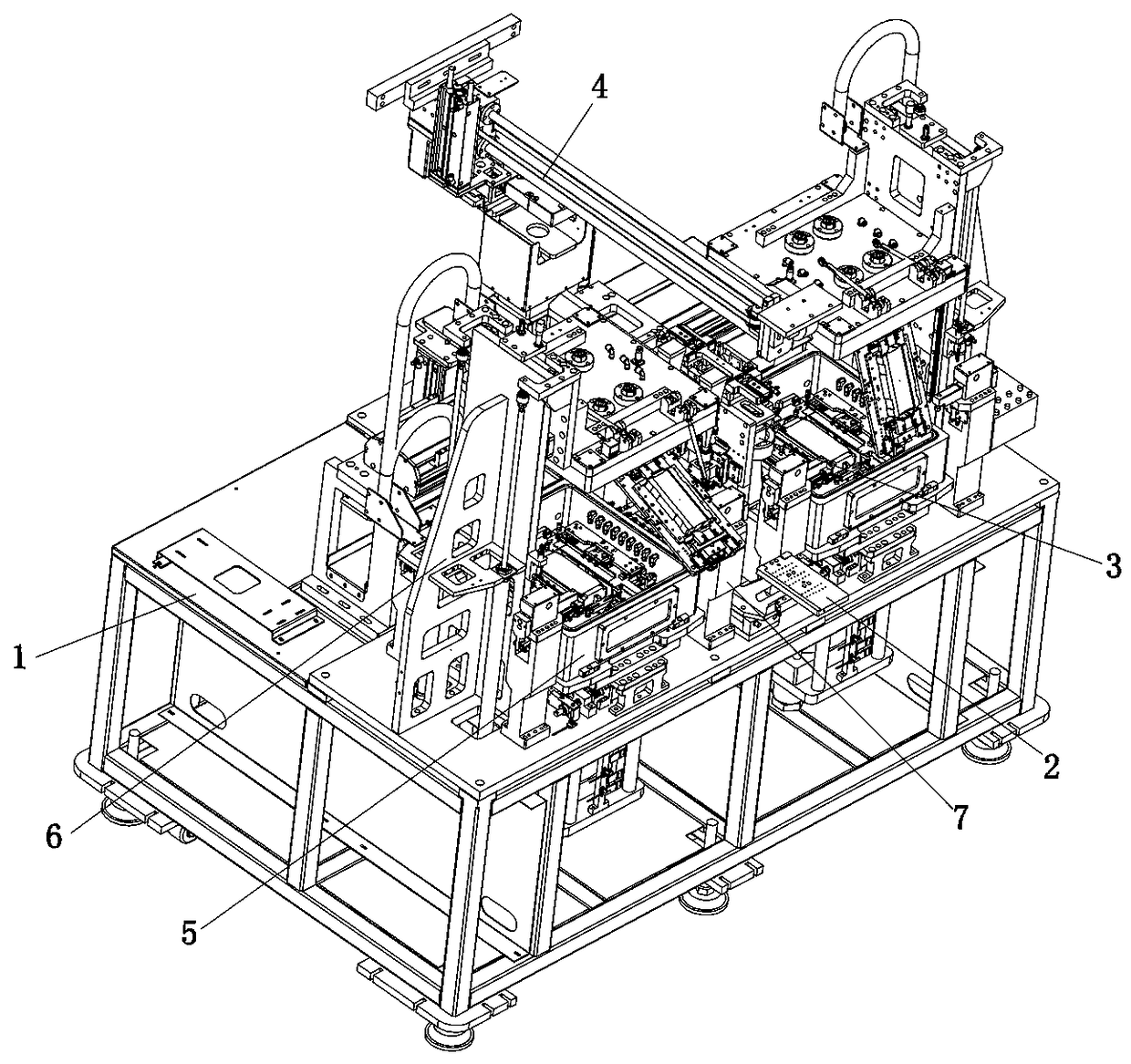

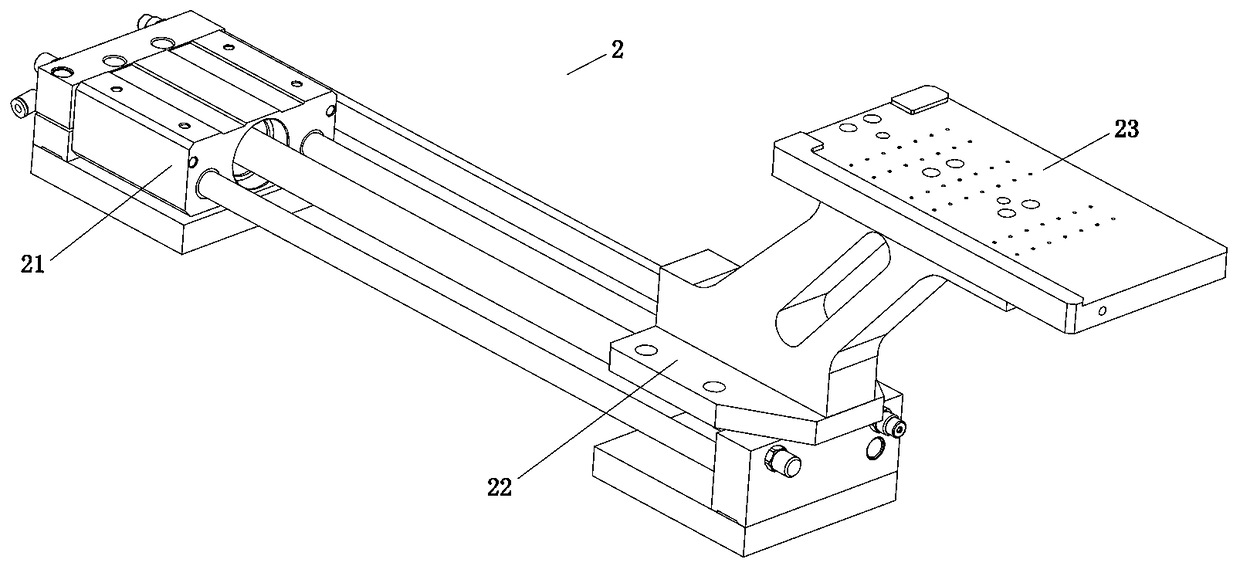

[0054] Such as Figure 1 to Figure 21As shown, the technical solution adopted by the present invention is as follows: a lifting type 3D compatible automatic film sticking machine, which is used to automatically stick the film material on the screen, including the upper film platform 2, the transfer platform 3, the film taking manipulator 4, the lower chamber Components and upper cavity components, wherein, the above-mentioned lower cavity component and the upper cavity component are arranged up and down correspondingly to form a film sticking mechanism, and the film sticking mechanism includes two sets, which are respectively arranged on the frame 1 at intervals; the above-mentioned upper film platform 2 is set between the two film sticking mechanisms , the film material to be attached is placed on the upper film platform 2; the above-mentioned transfer platform 3 is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com