Machine arm quick-release structure for multi-rotor unmanned aerial vehicle

A technology of multi-rotor unmanned and aircraft-used aircraft, applied in the direction of rotorcraft, unmanned aircraft, fuselage, etc., can solve the problems of non-detachable, large storage space, waste of space, etc., to achieve convenient portability and transportation, guarantee The effect of expanding speed and reducing storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

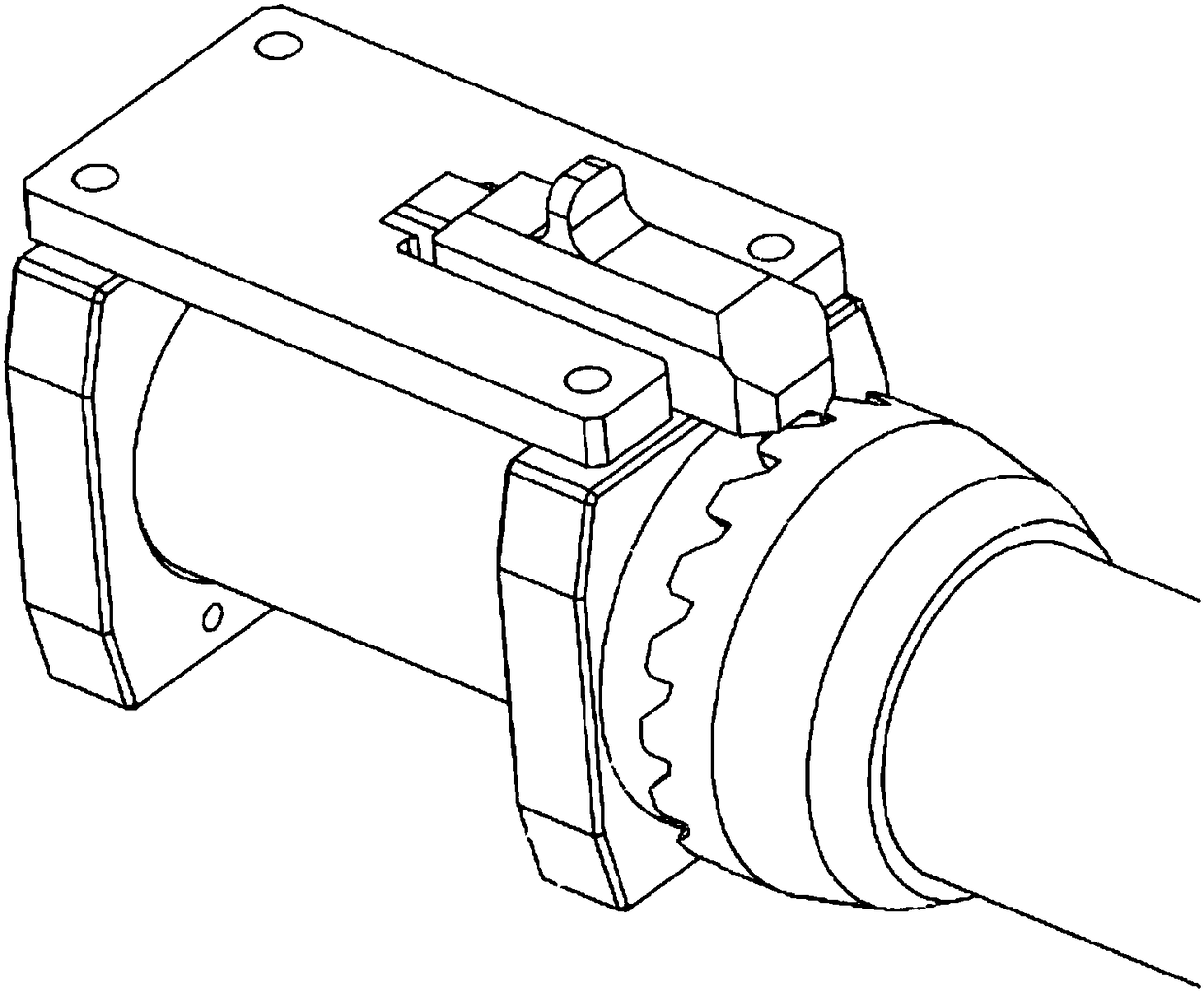

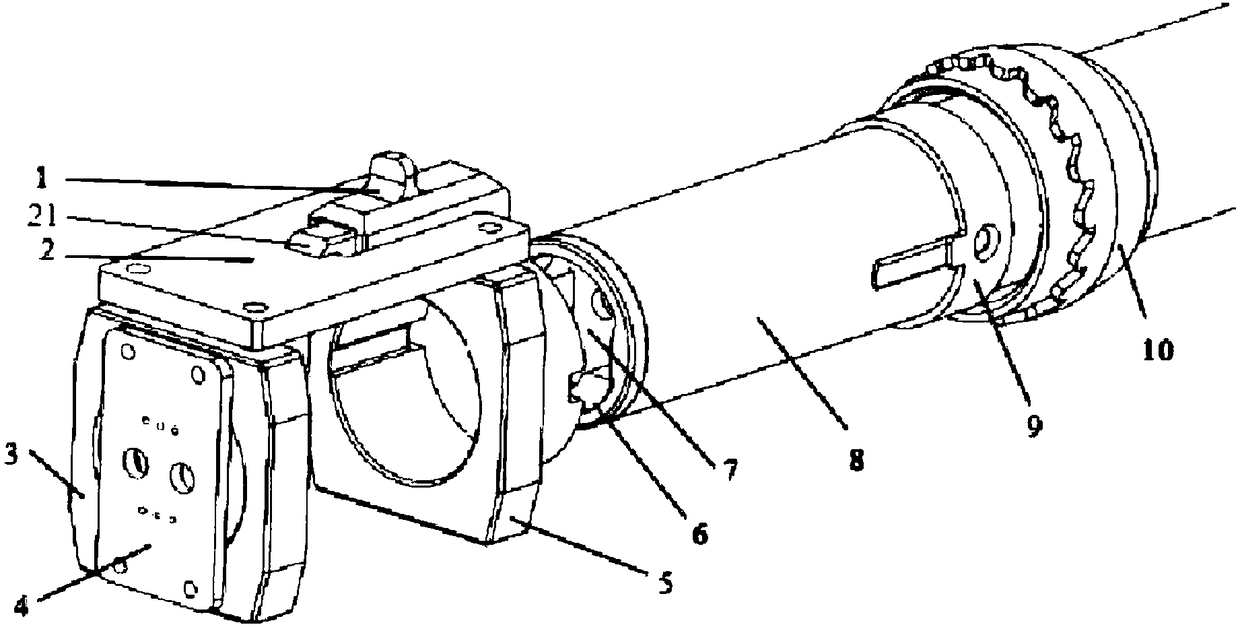

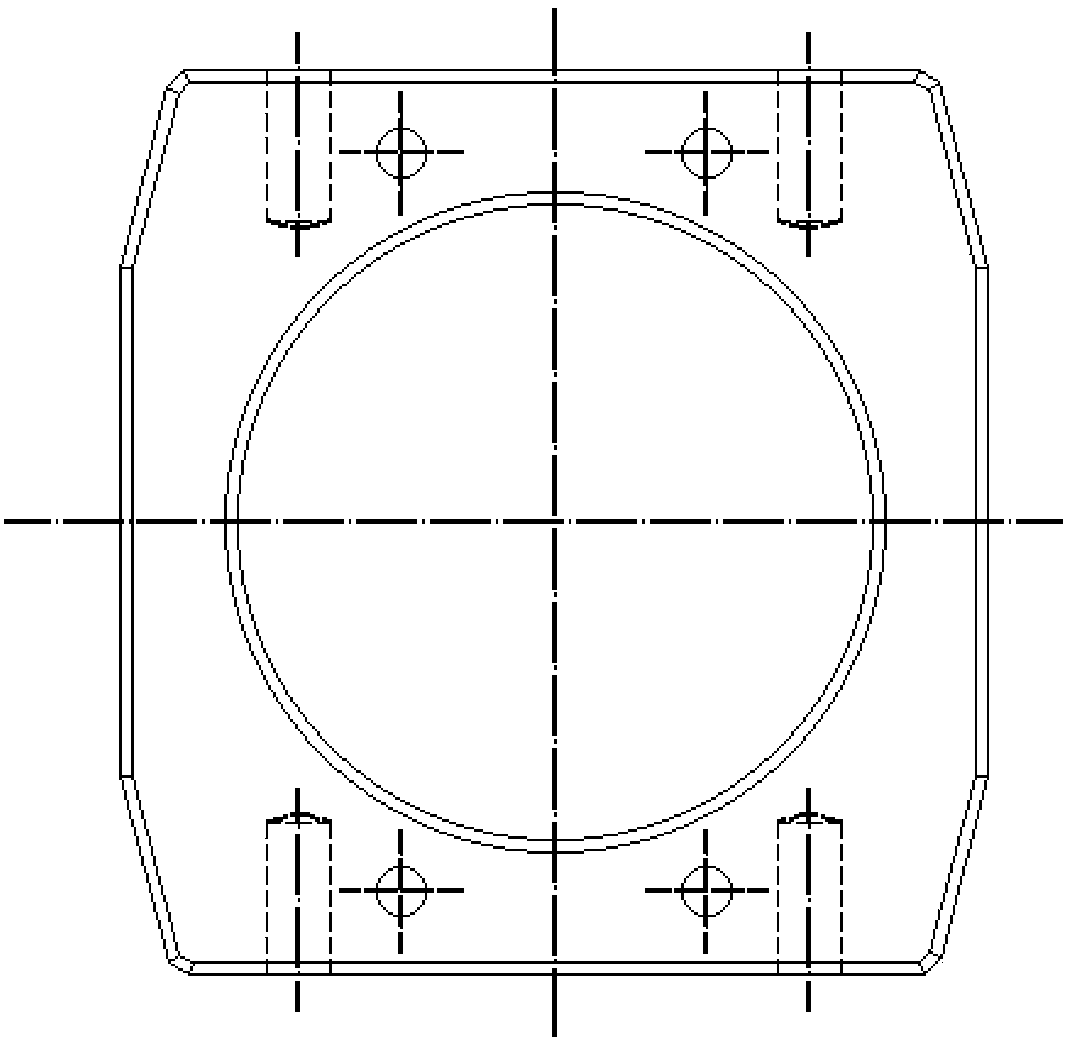

[0029] Such as figure 1 with figure 2 As shown, a multi-rotor UAV with a quick-release arm structure is divided into two parts, wherein the lock 1, the support plate 2, the lock guide rail 21, the fulcrum A3, the fuselage socket plate 4, and the fulcrum B5 are installed on the fuselage On the center plate, the center plate of the fuselage needs to design the corresponding positions according to the installation holes of the fulcrum A3 and the fulcrum B5. The fulcrum A3 and the fulcrum B5 are sequentially provided with round holes coaxial with the center line, and are connected with the support plate 2 by screws; The inner liner 6, the arm socket plate 7, the arm limiter 9, and the sleeve 10 are installed on the arm 8. The arm 8 needs to use carbon tubes with a diameter of 25mm, and the position needs to be reserved according to the installation hole of the arm inner liner 6. , and is fixedly connected with the machine arm lining 6, the machine arm 8 is covered with the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com