Wastewater recovery device of iso-butane dehydrogenation device

A waste water recycling and isobutane technology, applied in natural water treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste, unfavorable, unenvironmental protection, etc., to reduce water consumption, strengthen Water quality, water quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

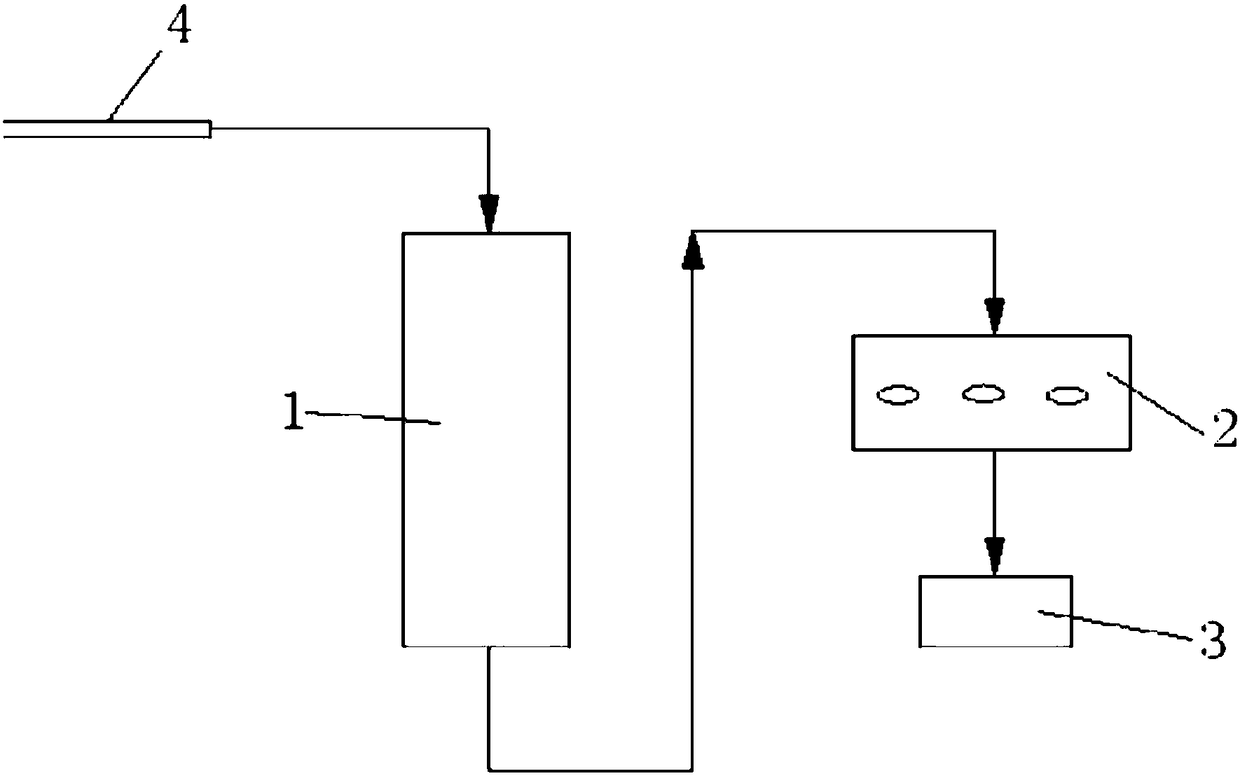

[0014] as attached figure 1 Shown, a kind of isobutane dehydrogenation device waste water recovery device, it comprises molecular sieve tank 1, cool water tower 2, circulating pool 3, the water inlet of described molecular sieve tank 2 passes the reaction condensate of pipeline and isobutane dehydrogenation device Pipeline 4 is connected, and the water outlet of described molecular sieve tank 1 is connected the water inlet of described cooling tower 2 by pipeline, and the water outlet of described cooling tower 2 connects described circulating pool 3, and circulating pool 3 connects the isobutane dehydrogenation device Circulating water system.

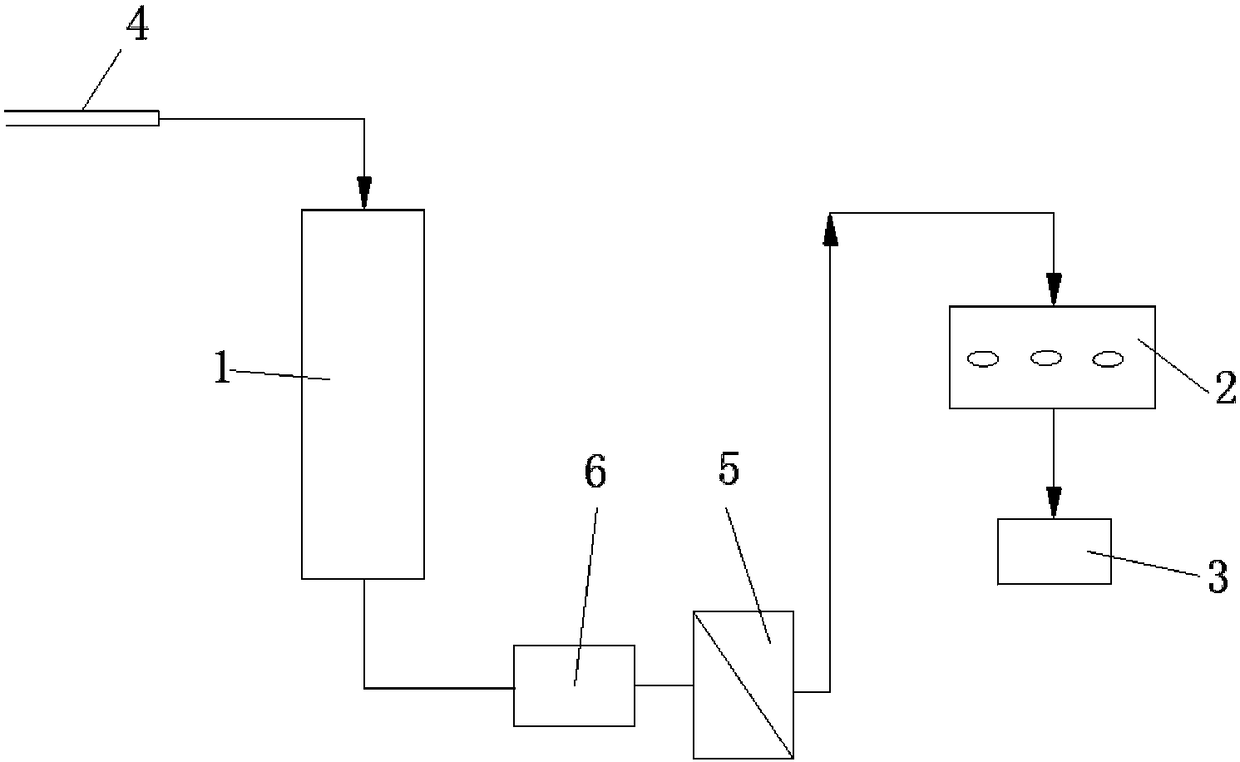

[0015] In order to further effectively remove oil and pollutants in water, if attached figure 2 As shown, in the present invention, a cooler 6 and a membrane separator 5 are sequentially connected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com