A method for completely removing acidic substances in crude vinyl chloride gas

A technology for crude vinyl chloride and acidic substances, which is applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., and can solve the problems of high loss of vinyl chloride VCM, waste of lye, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

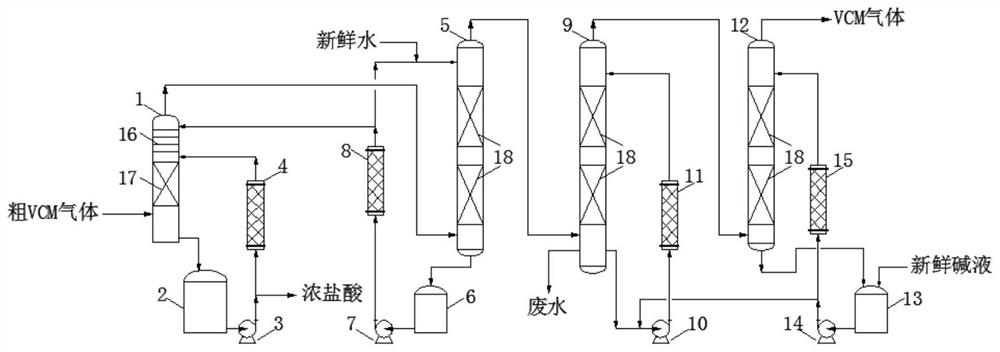

[0025] Such as figure 1 As shown, a method for completely removing acidic substances in crude vinyl chloride gas, the device used includes hydrogen chloride absorption and alkali washing two parts, the hydrogen chloride absorption part includes hydrogen chloride combined absorption tower 1, concentrated hydrochloric acid tank 2, concentrated hydrochloric acid pump 3, Concentrated hydrochloric acid cooler 4, dilute hydrochloric acid tower 5, dilute hydrochloric acid tank 6, dilute hydrochloric acid pump 7, dilute hydrochloric acid cooler 8, hydrogen chloride combined absorption tower 1 is composed of upper bubble-cap tray 16 and lower structured packing 17 , the feed position of dilute hydrochloric acid is above the bubble-cap tray 16, the feed position of concentrated hydrochloric acid is between the bubble-cap tray 16 and the structured packing 17, forming two-stage absorption in the hydrogen chloride combined absorption tower 1; the alkali washing part is composed of two stag...

Embodiment 2

[0030] Such as figure 1 Shown, a kind of method of completely removing acidic substance in the crude vinyl chloride gas, used device is the same as embodiment 1.

[0031] Its process flow is: including the hydrogen chloride absorption process and the double-tower alkali washing process. The crude vinyl chloride gas from the converter enters the hydrogen chloride combined absorption tower 1 from the bottom, and passes through the concentrated hydrochloric acid tank 2 and the concentrated hydrochloric acid tank 1 in sequence in the hydrogen chloride combined absorption tower 1. The concentrated hydrochloric acid circulated by the hydrochloric acid pump 3 and the concentrated hydrochloric acid cooler 4 and the dilute hydrochloric acid from the dilute hydrochloric acid tower 5 are countercurrently contacted to absorb hydrogen chloride gas. 3 / h; the crude vinyl chloride gas coming out from the top of the hydrogen chloride combined absorption tower 1 enters the bottom of the dilute...

Embodiment 3

[0035] Such as figure 1 Shown, a kind of method of completely removing acidic substance in the crude vinyl chloride gas, used device is the same as embodiment 1.

[0036] Its process flow is: including the hydrogen chloride absorption process and the double-tower alkali washing process. The crude vinyl chloride gas from the converter enters the hydrogen chloride combined absorption tower 1 from the bottom, and passes through the concentrated hydrochloric acid tank 2 and the concentrated hydrochloric acid tank 1 in sequence in the hydrogen chloride combined absorption tower 1. The concentrated hydrochloric acid circulated by the hydrochloric acid pump 3 and the concentrated hydrochloric acid cooler 4 and the dilute hydrochloric acid from the dilute hydrochloric acid tower 5 are countercurrently contacted to absorb hydrogen chloride gas. 3 / h; the crude vinyl chloride gas coming out from the top of the hydrogen chloride combined absorption tower 1 enters the bottom of the dilute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com