High-manganese pipeline steel and preparation method thereof

A technology of pipeline steel and high manganese, which is applied in the field of metal material rolling, can solve the problems of weak deformation resistance and high yield strength, and achieve the effects of energy saving, low yield strength ratio, simple rolling and cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high manganese pipeline steel whose composition by weight percentage is C 0.46%, Si 0.21%, Mn 15%, P0.010%, S 0.002%, Al 0.02%, Mo 0.57%, Cr 0.98%, Nb 0.02%, V 0.034%, the balance is Fe and unavoidable impurities.

[0036] The preparation method steps of the high manganese pipeline steel are as follows:

[0037] Smelted according to the set composition, cast into billet, the composition by weight percentage is C 0.46%, Si 0.21%, Mn 15%, P 0.010%, S 0.002%, Al 0.02%, Mo 0.57%, Cr 0.98%, Nb 0.02% , V 0.034%, the balance is Fe and unavoidable impurities;

[0038] Heat the billet to 1200°C and keep it warm for 2 hours;

[0039] Carry out rolling, the starting rolling temperature is 1160°C, the total reduction is 86%, and the finishing rolling temperature is 930°C;

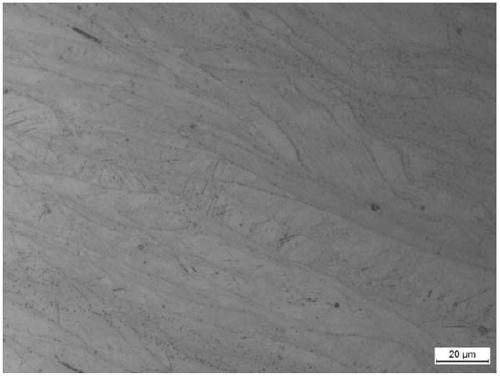

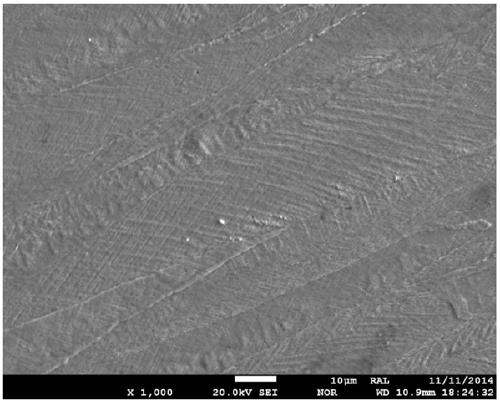

[0040] After rolling, air-cool to room temperature to produce high-manganese pipeline steel. The microstructure under the scanning electron microscope is as follows: figure 2 As shown, take another sample...

Embodiment 2

[0046] A high manganese pipeline steel whose composition by weight percentage is C 0.65%, Si 0.28%, Mn 19%, P0.006%, S 0.003%, Al 0.04%, Mo 0.76%, Cr 1.07%, Nb 0.03%, V 0.058%, the balance is Fe and unavoidable impurities;

[0047] The preparation method steps of the high manganese pipeline steel are as follows:

[0048] Smelted according to the set composition, cast into billet, the composition by weight percentage is C 0.65%, Si 0.28%, Mn 19%, P 0.006%, S 0.003%, Al 0.04%, Mo 0.76%, Cr 1.07%, Nb 0.03% , V 0.058%, the balance is Fe and unavoidable impurities;

[0049] Heat the billet to 1250°C and keep it warm for 1h;

[0050] Carry out rolling, the starting rolling temperature is 1171°C, the total reduction is 89%, and the final rolling temperature is 830°C;

[0051] After rolling, air-cool to room temperature to produce high-manganese pipeline steel. The structure observed under a microscope is a single-phase austenite structure;

[0052] The finished high manganese pip...

Embodiment 3

[0057] A high manganese pipeline steel whose composition by weight percentage is C 0.5%, Si 0.26%, Mn 15.2%, P0.002%, S 0.001%, Al 0.03%, Mo 0.6%, Cr 0.92%, Nb 0.026%, V 0.047%, the balance is Fe and unavoidable impurities.

[0058] The preparation method steps of the high manganese pipeline steel are as follows:

[0059] Smelted according to the set composition, cast into billet, the composition is C 0.5%, Si 0.26%, Mn15.2%, P 0.002%, S 0.001%, Al 0.03%, Mo 0.6%, Cr 0.92%, Nb 0.026% by weight %, V 0.047%, the balance is Fe and unavoidable impurities;

[0060] Heat the billet to 1230°C and keep it warm for 1.5h;

[0061] Carry out rolling, the starting rolling temperature is 1193°C, the total reduction is 87%, and the final rolling temperature is 880°C;

[0062] After rolling, air-cool to room temperature to produce high-manganese pipeline steel. The structure observed under a microscope is a single-phase austenite structure;

[0063] The finished high manganese pipeline s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com