Patents

Literature

30results about How to "Simple cooling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

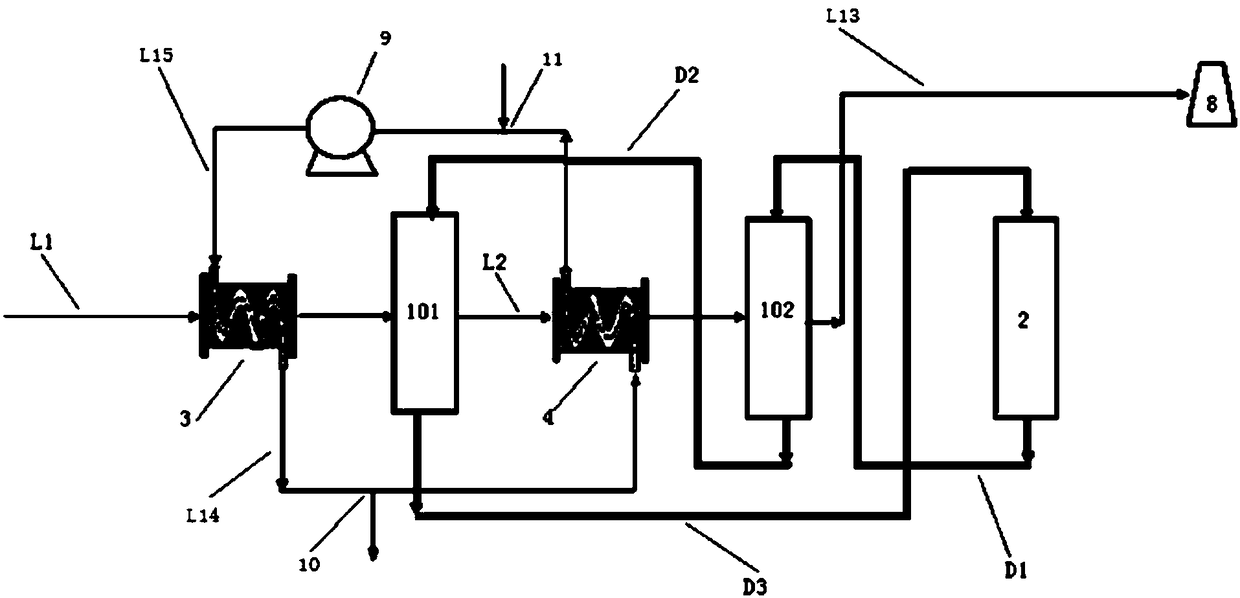

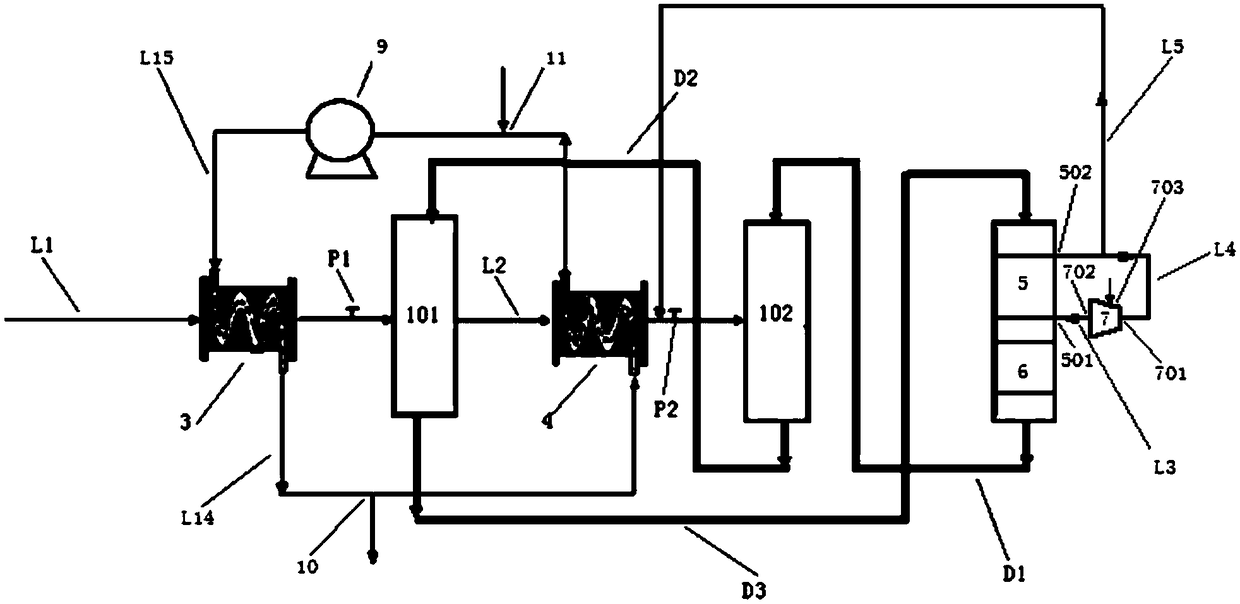

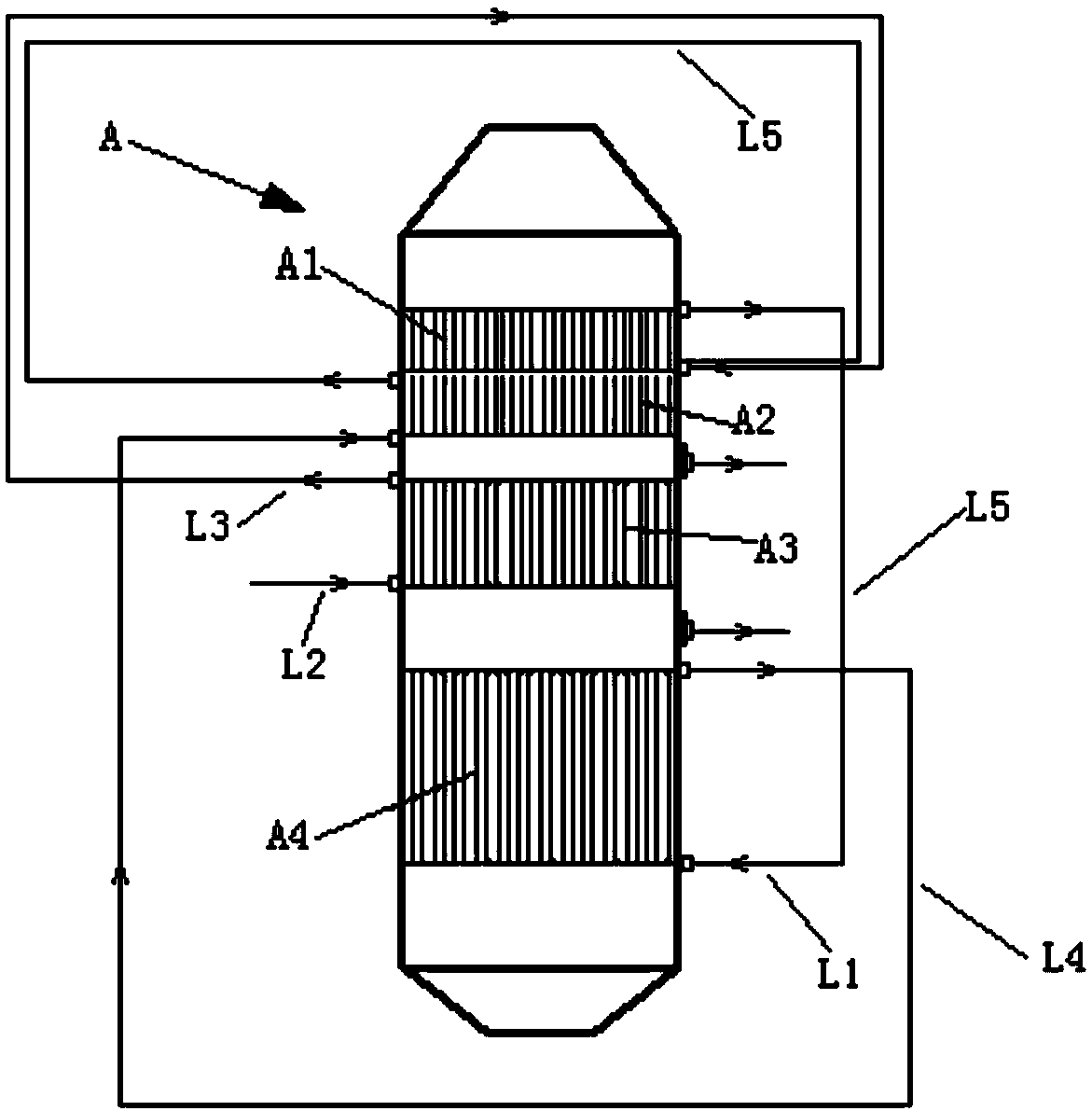

Activated carbon treatment system for improving waste heat utilization rate and denitration rate and using method thereof

ActiveCN108939808AGuaranteed temperatureImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationActivated carbonFlue gas

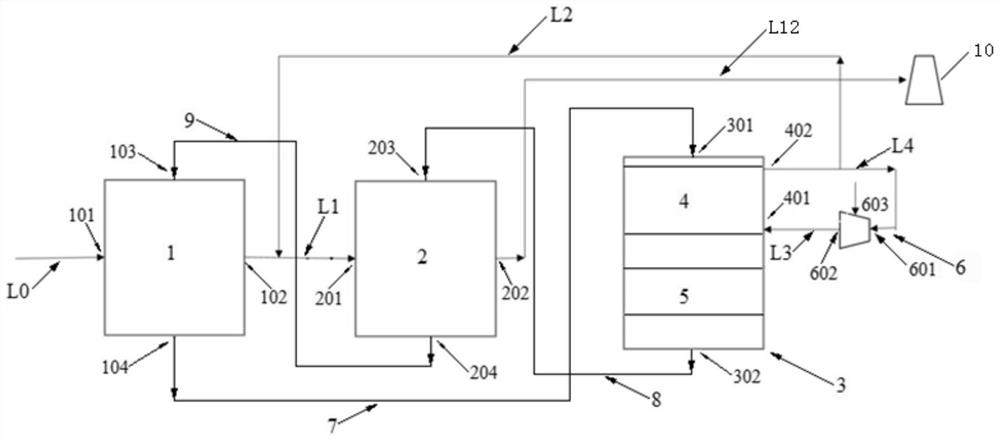

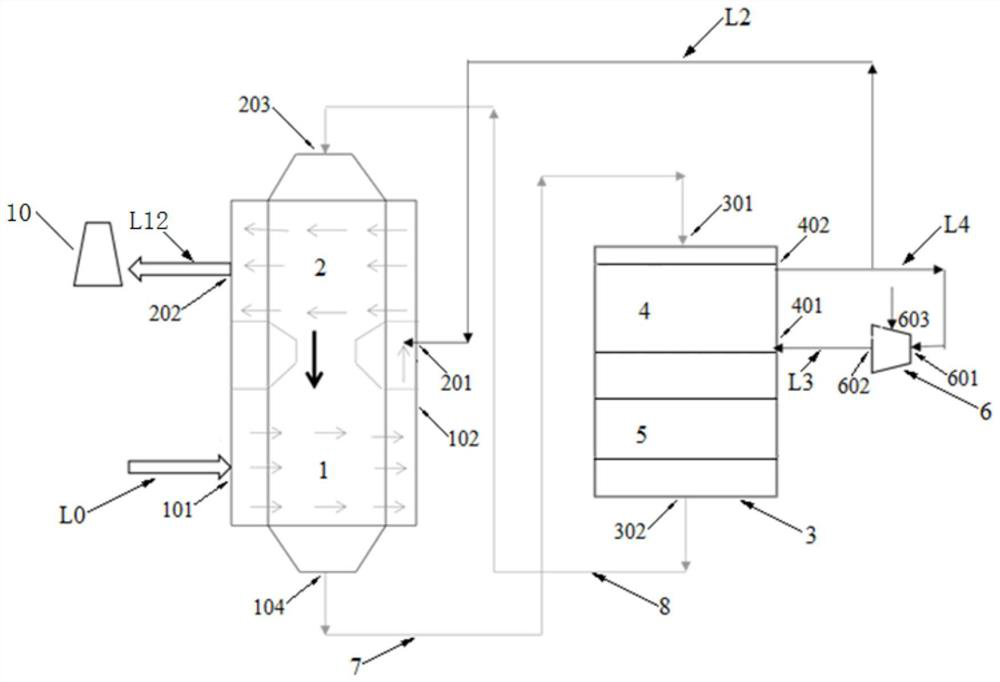

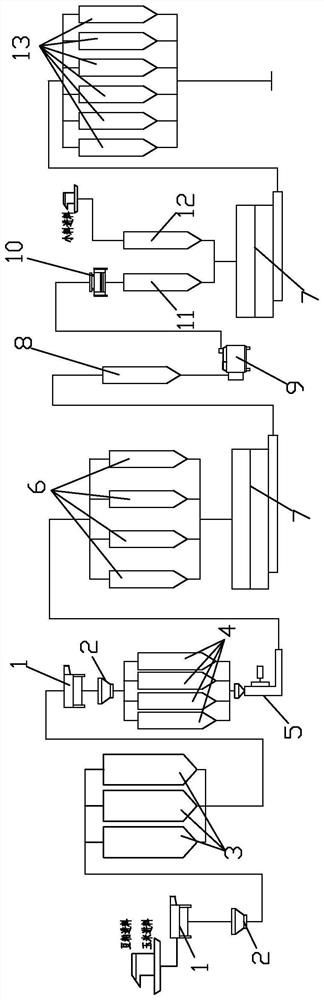

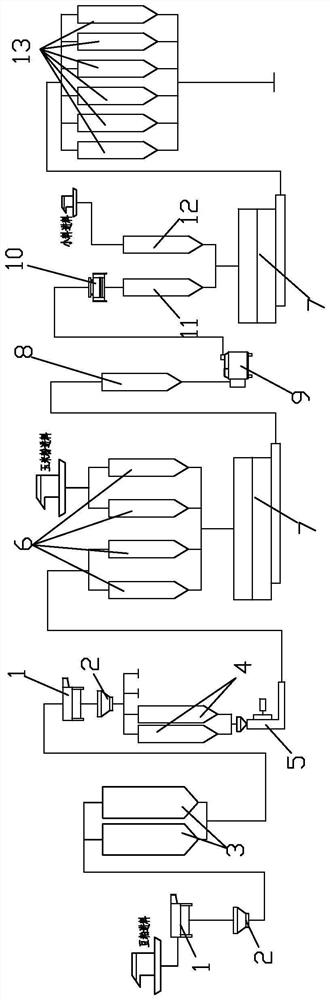

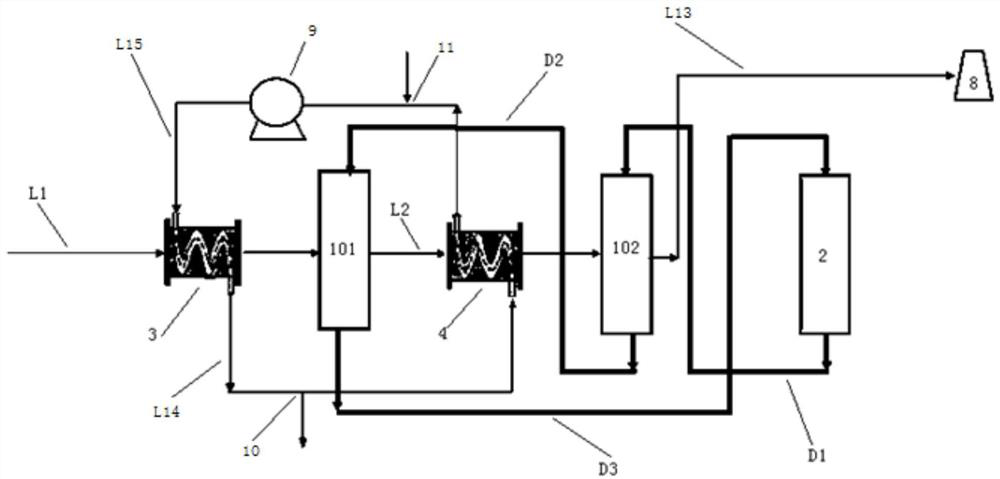

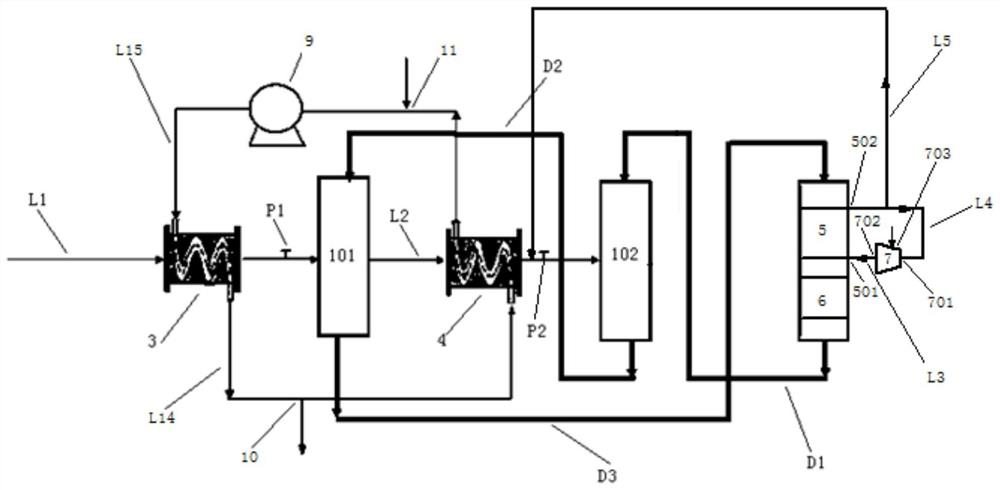

The invention provides an activated carbon treatment system for improving waste heat utilization rate and denitration rate and a using method thereof. Heat exchangers are separately disposed before flue gas is input into a first-stage adsorption column and a second-stage adsorption column, the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column is controlled, thereby ensuring the temperature of desulfurization and denitration. The activated carbon treatment system utilizes high-temperature flue gas (about 150-170 DEG C) after a main exhaust blower, adopts a mode of heat exchange, artificially controls the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column, and enables the efficiency of removal of SO<2> and NO<x>; and the utilization rate of the high-temperature flue gas after the main exhaust blower is increased, and the temperature of the flue gas entering a desulfurization tower and a denitration tower is controlled to improve the efficiency of desulfurization and denitration.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

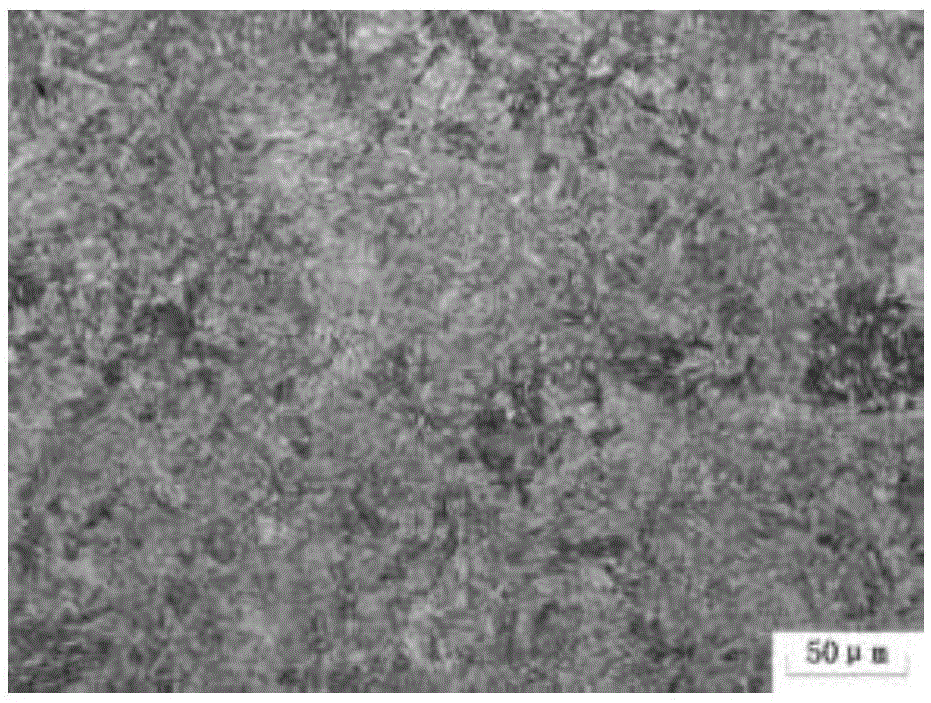

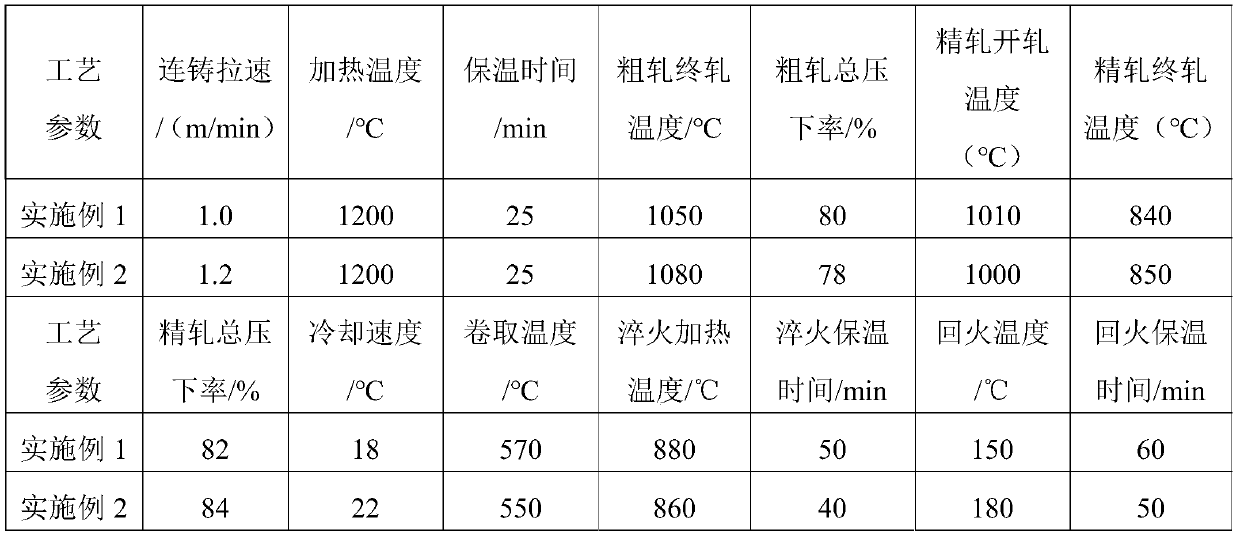

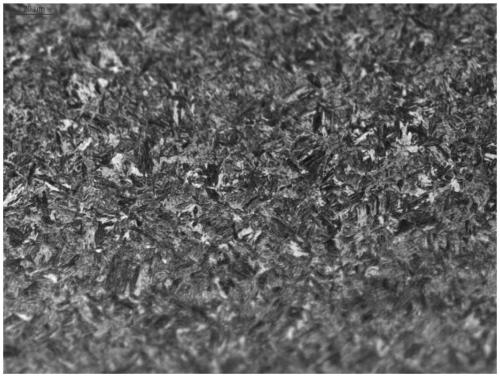

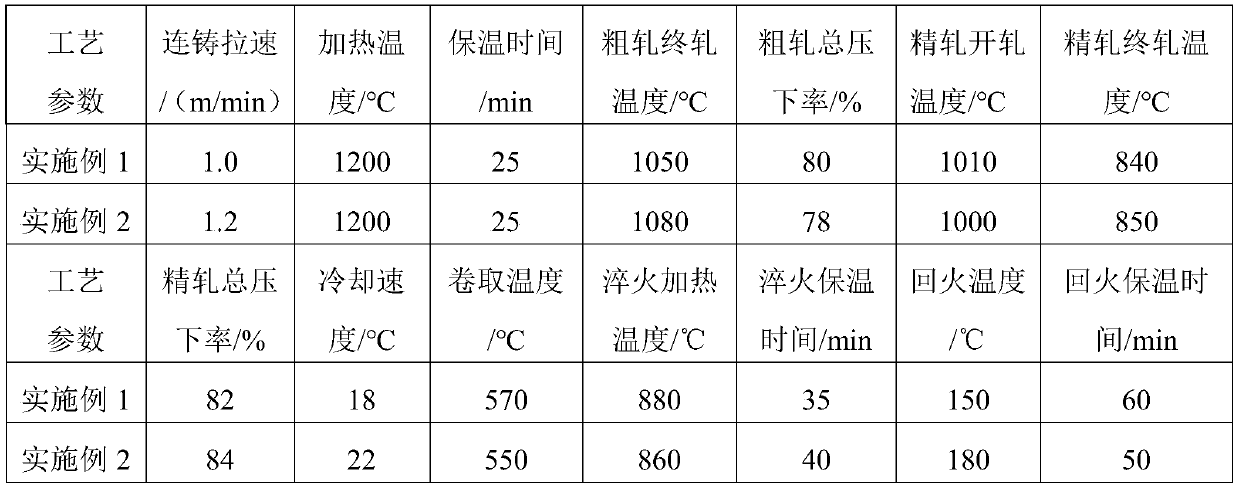

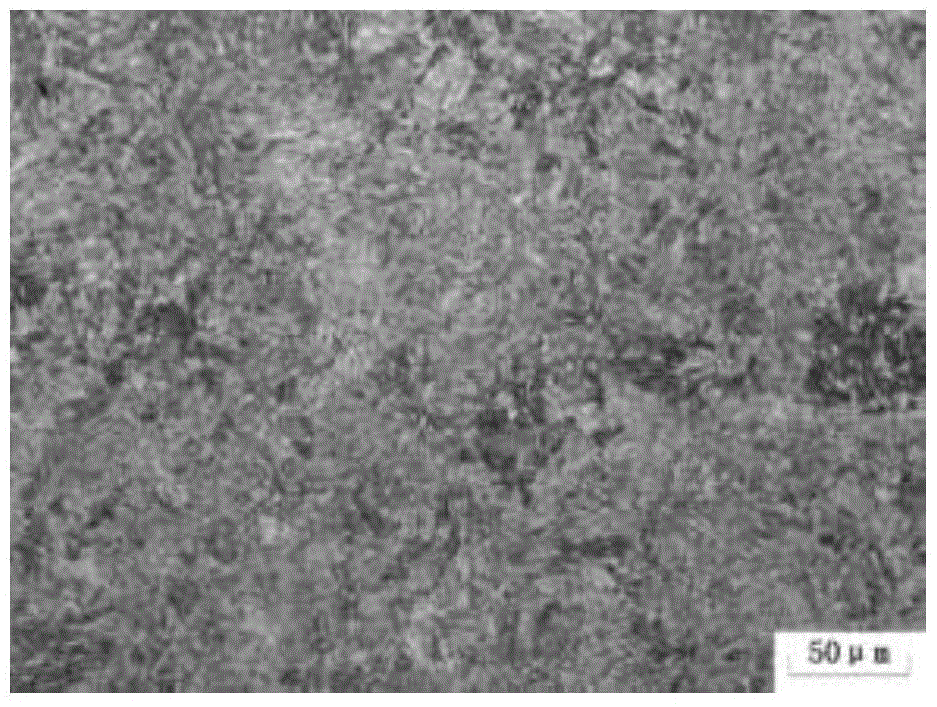

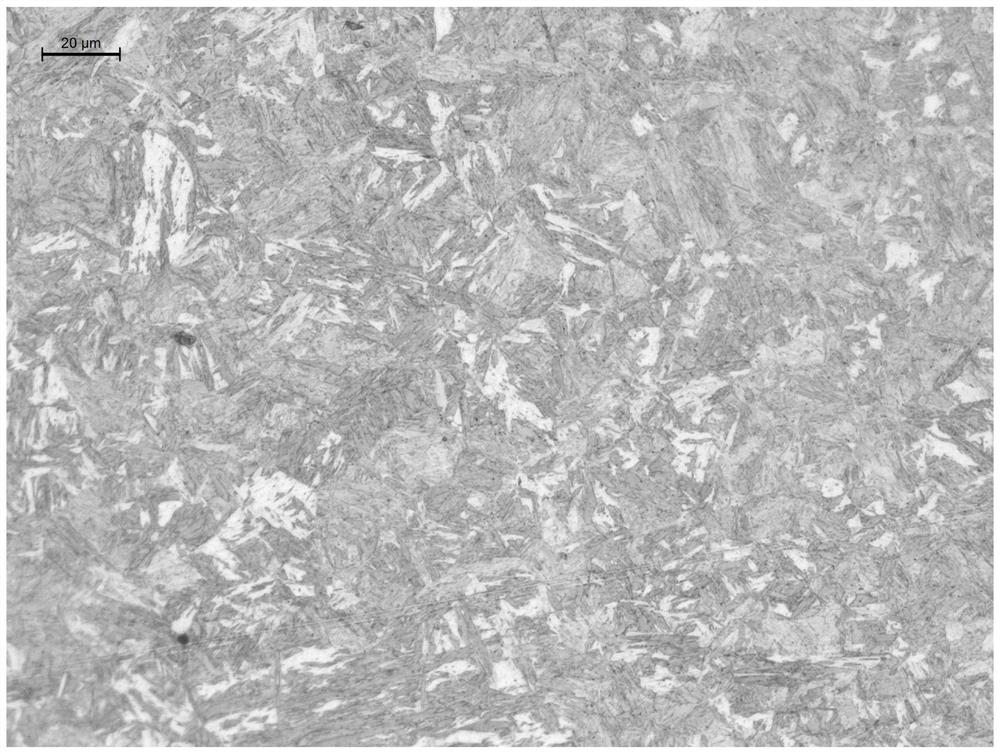

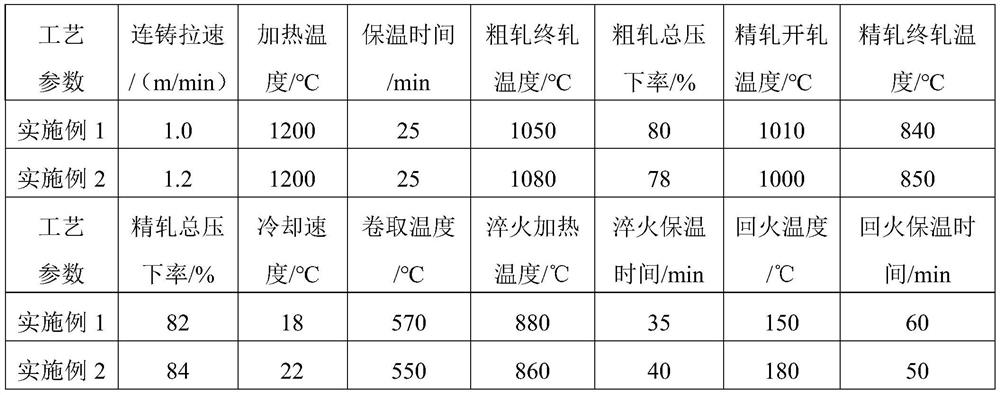

Steel for ultra-high-strength sucker rod and production method thereof

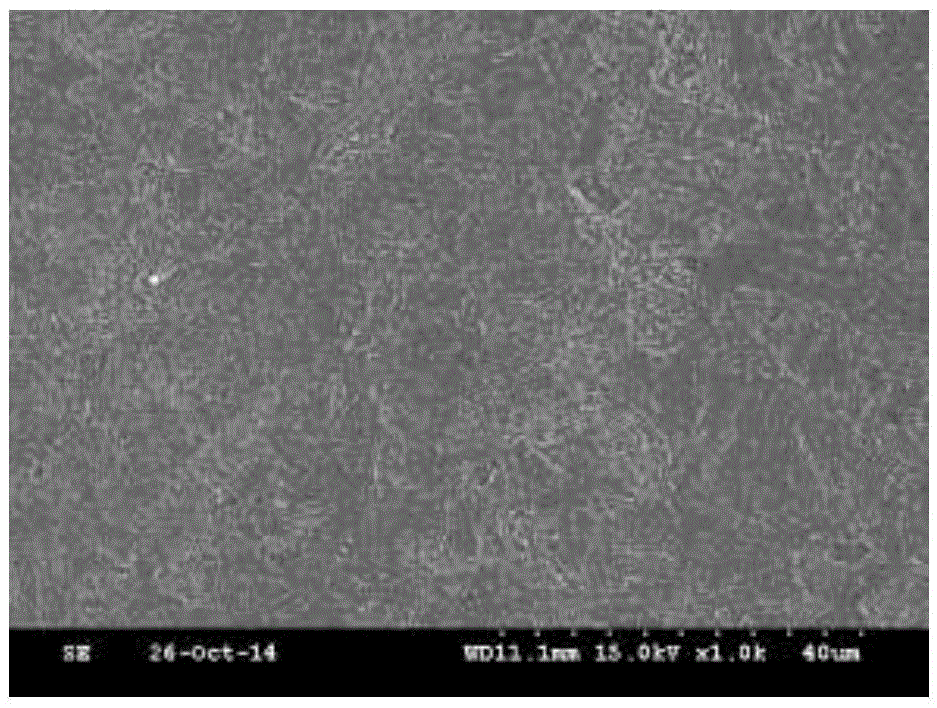

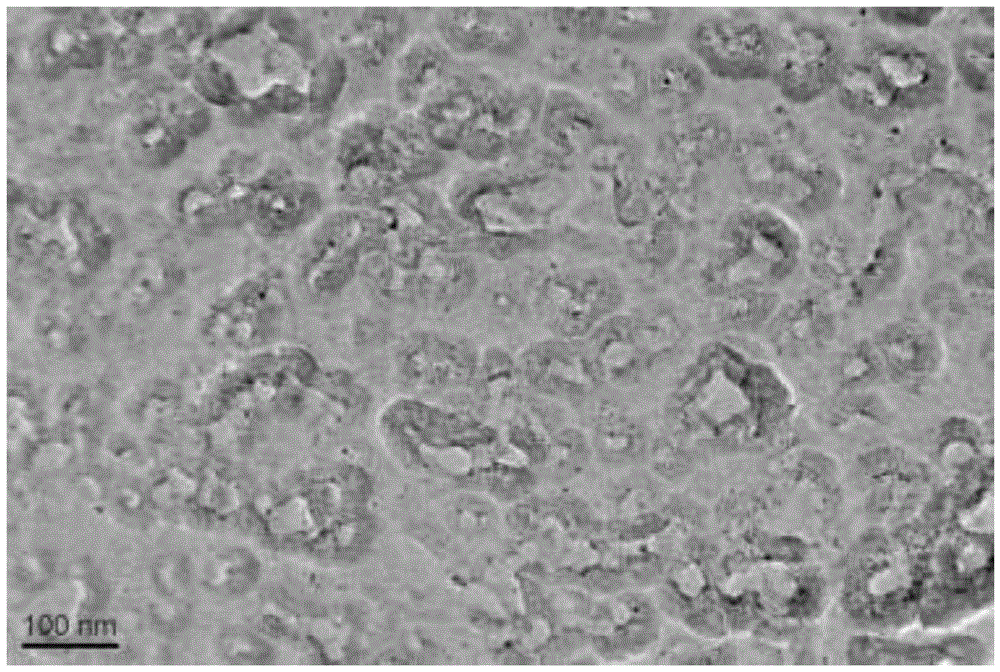

ActiveCN105624562ASimple cooling processImprove corrosion resistanceComposite nanoparticlesUltimate tensile strength

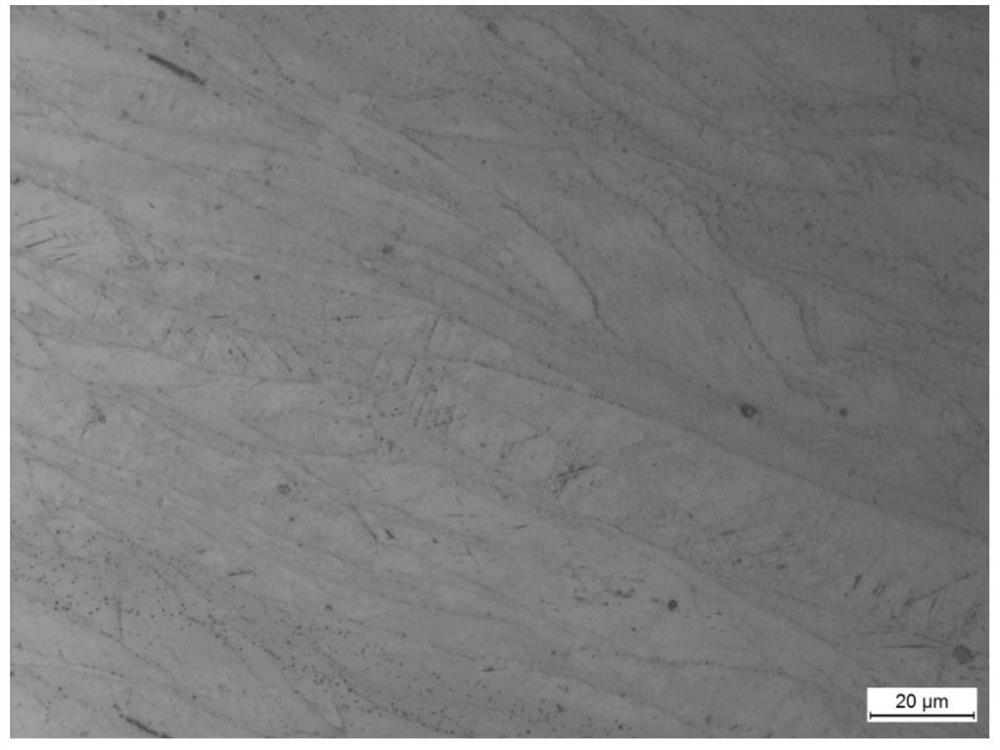

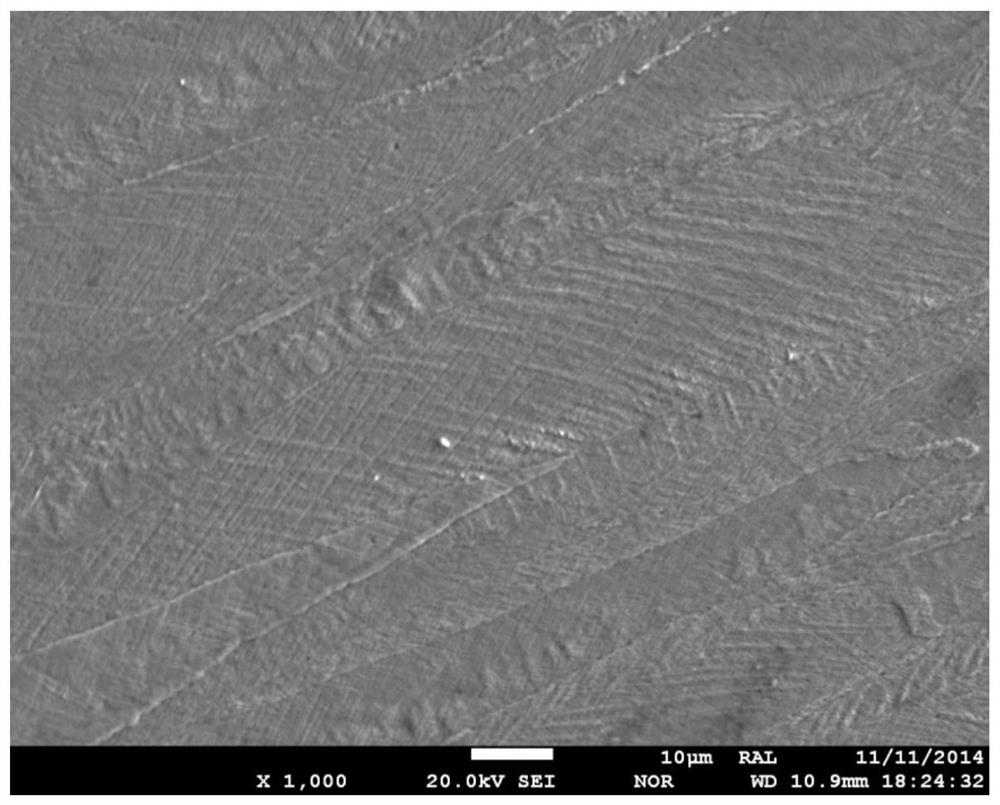

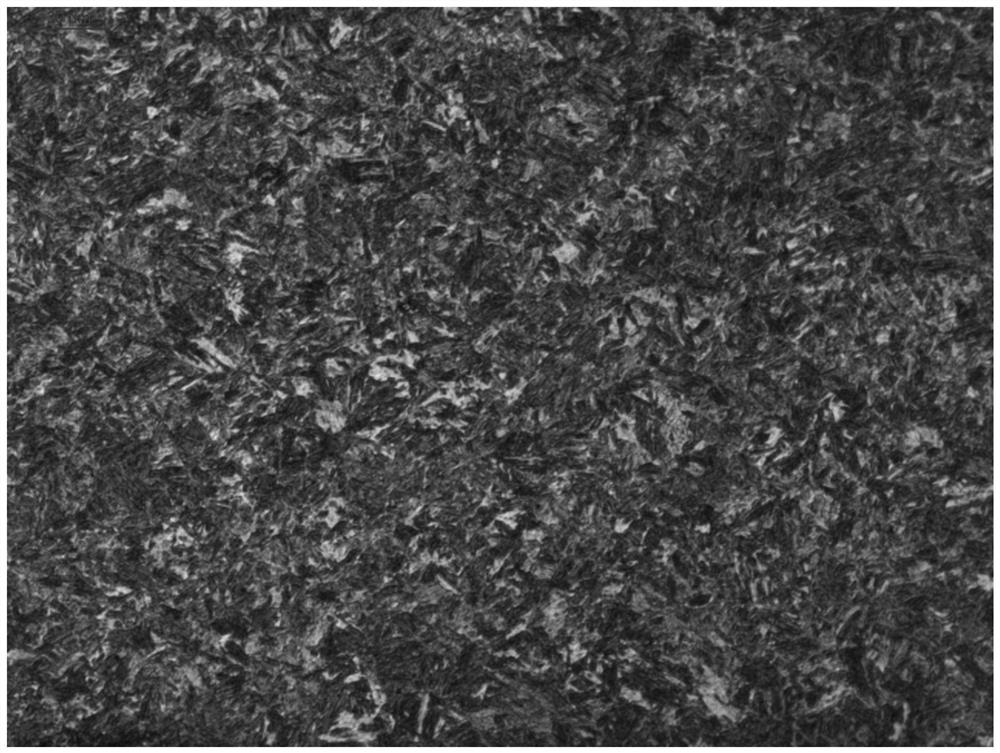

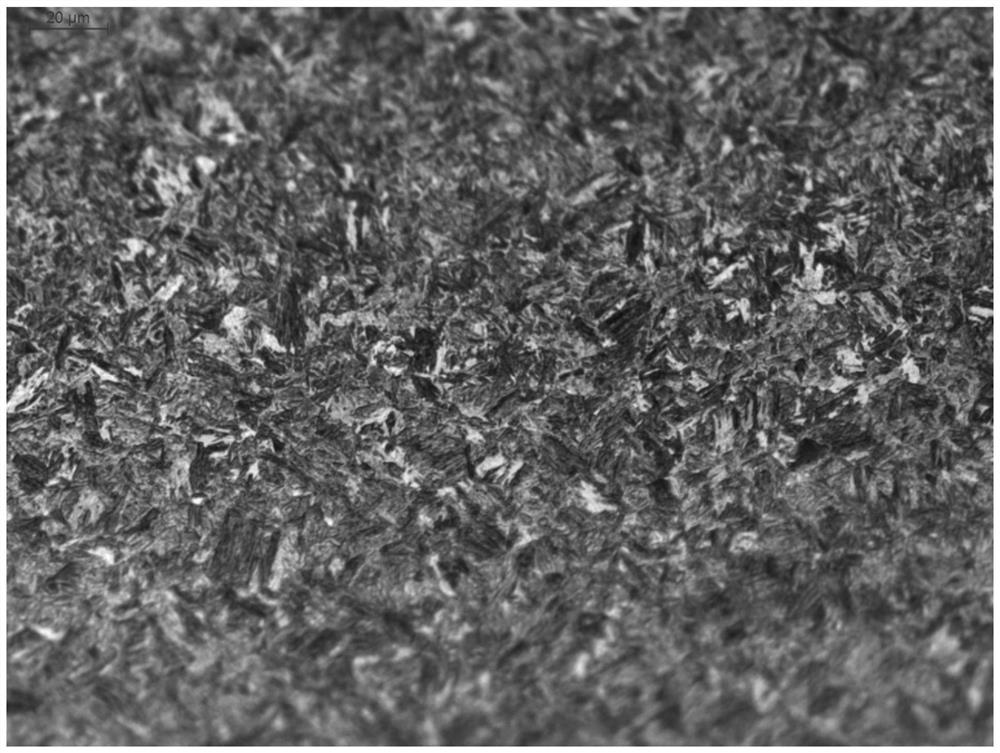

The invention relates to steel for an ultra-high-strength sucker rod and a production method thereof. The steel for an ultra-high-strength sucker rod is prepared from the following components: 0.07-0.13wt% of C, 4.0-7.0wt% of Cr, less than 0.50wt% of Mn, less than 0.50wt% of Si, 0.30-0.60wt% of Mo, 0.05-0.15wt% of V, 0.01-0.03wt% of Ti, less than 0.008wt% of P, less than 0.002wt% of S, 0.01-0.05wt% of Al, and the balance of Fe and unavoidable impurities; the steel also can contain less than 0.50wt% of Ni. For the steel for an ultra-high-strength sucker rod, a high-temperature tempered martensite structure can be obtained by adopting a super-clean steel smelting technology with low cost and a heat treatment process including normalizing and high-temperature tempering, nano Cr, V, Mo composite nanoparticles are used as precipitation strengthening phases, and the yield strength can reach 800MPa grade, and the steel disclosed by the invention has the corrosion resistance prior to that of KD-grade steel 20Cr2MoNiA for a sucker rod and can be used for producing H-grade ultra-high-strength corrosion-resistant steel sucker rods.

Owner:CENT IRON & STEEL RES INST +1

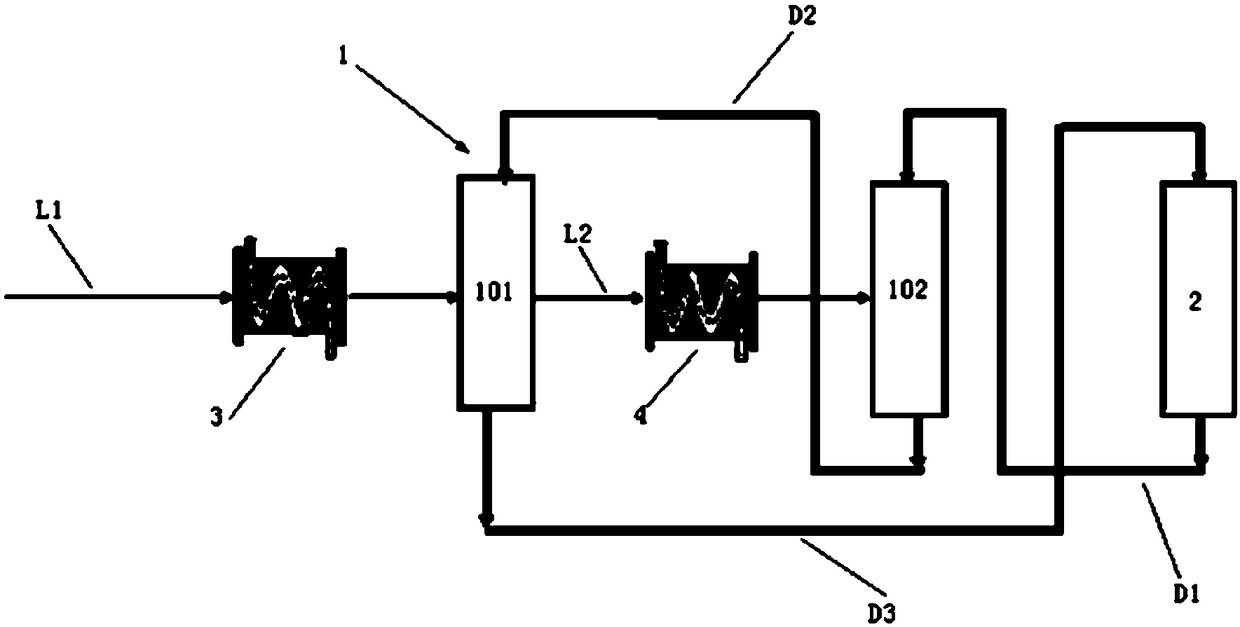

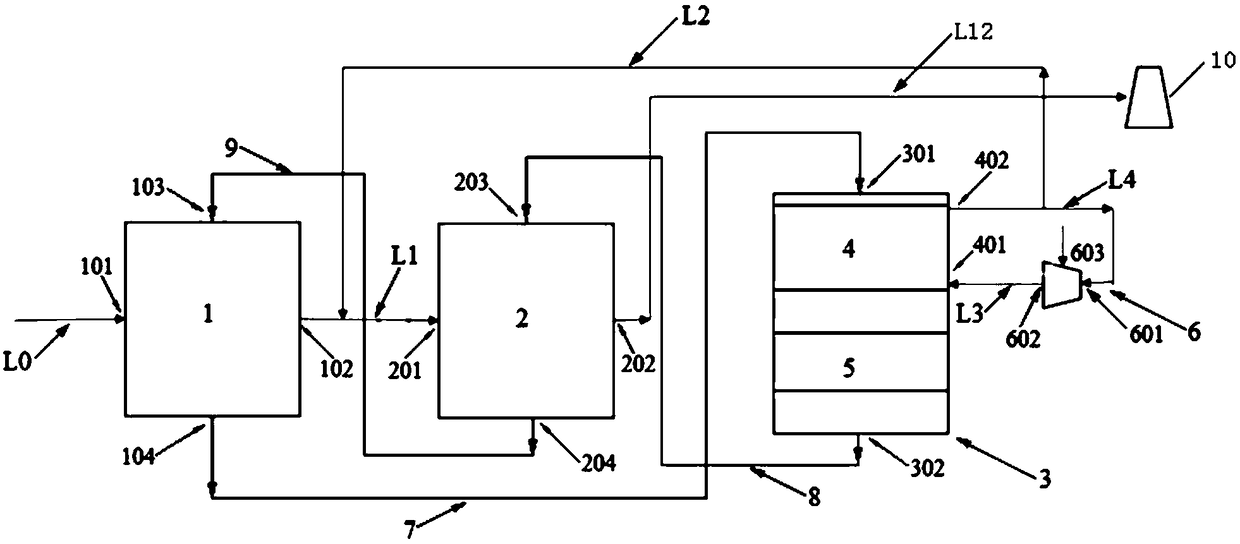

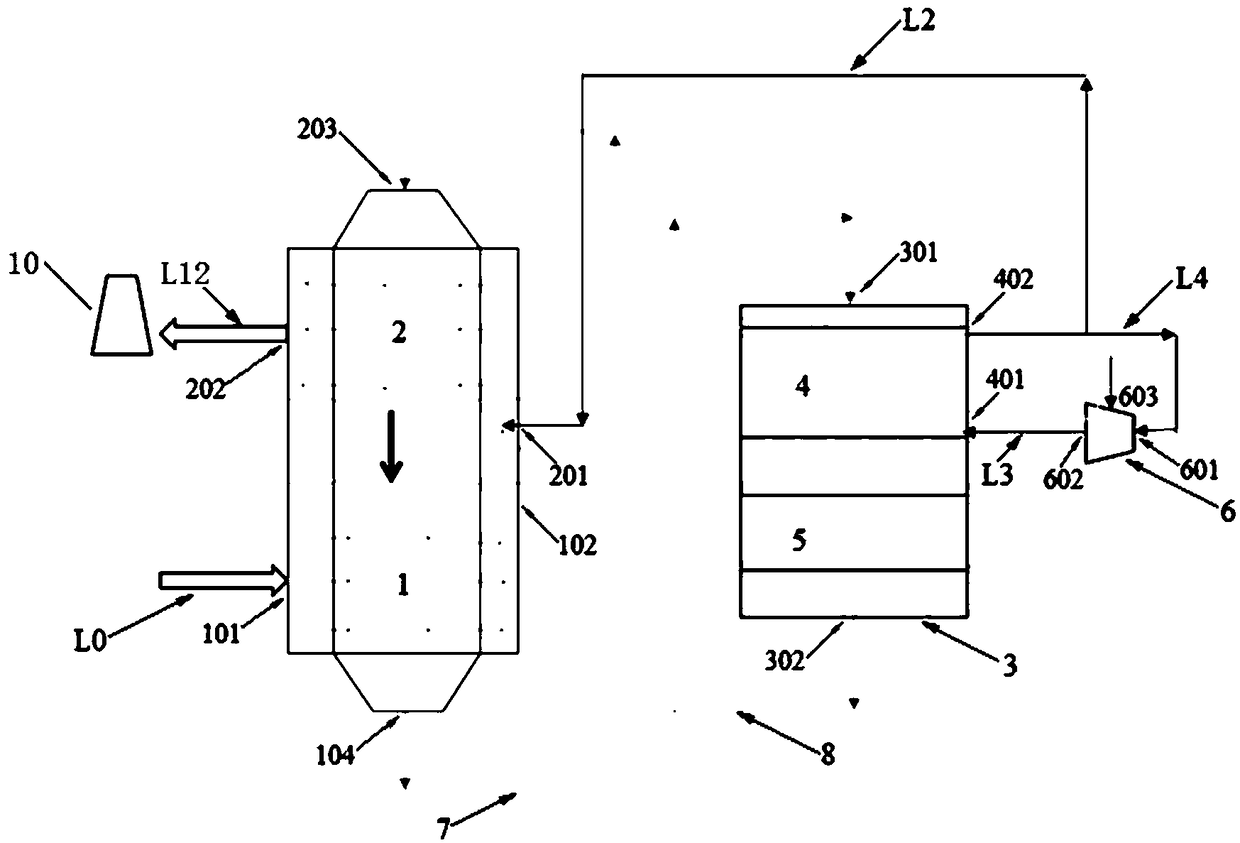

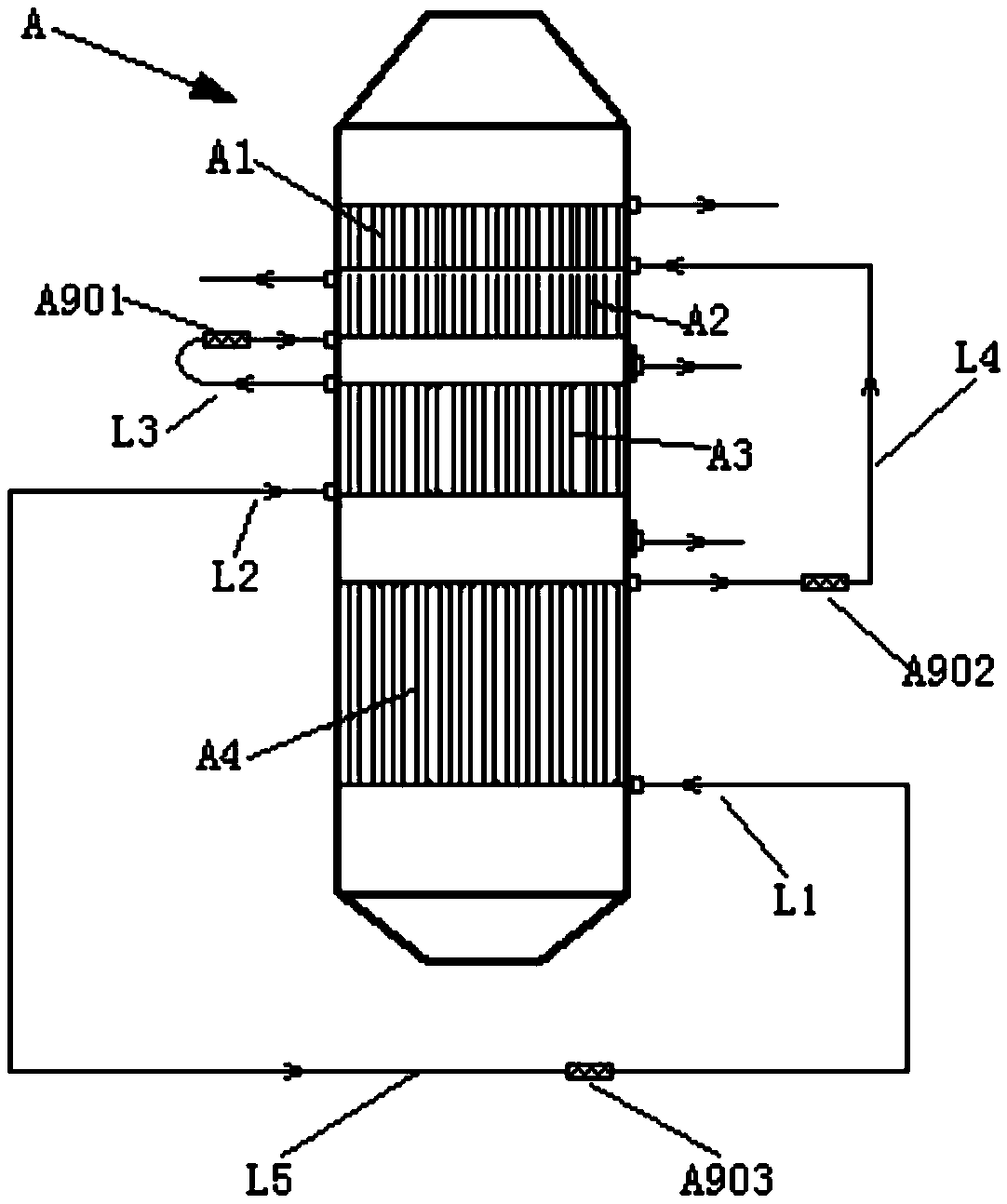

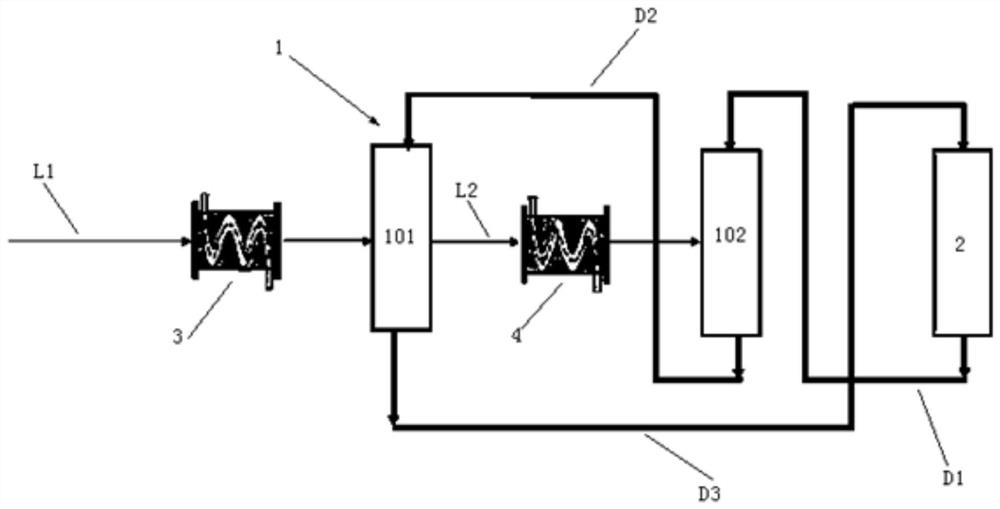

Flue gas purification device for improving waste heat utilization rate and denitration rate and using method thereof

ActiveCN108939807AImprove waste heat utilizationImprove denitrification rateGas treatmentDispersed particle separationActivated carbonFlue gas

According to a trend of flue gas, the flue gas purification device for improving waste heat utilization rate and denitration rate includes a primary adsorption column and a secondary adsorption columndisposed downstream the primary adsorption column. An original flue gas conveying pipeline is connected to a flue gas inlet of the primary adsorption column; a flue gas outlet of the primary adsorption column is connected to a flue gas inlet of the secondary adsorption column through a first pipeline; the device further comprises an analytical tower; a heating section and a cooling section are disposed on the analytical tower; the lower part of the heating section is provided with a heating section gas inlet, and the upper part of the heating section is provided with a heating section gas outlet; and the heating section gas outlet of the analytical tower is connected to the flue gas inlet of the secondary adsorption column by a second pipeline. The device introduces a part of exhausted hot air after heat exchange with to-be-analyzed activated carbon into the flue gas inlet of the secondary adsorption column, and on one hand, the concentration of exhausted SO<2> is removed, and simultaneously flue gas at the inlet of the secondary adsorption column is heated to improve the temperature of the flue gas.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

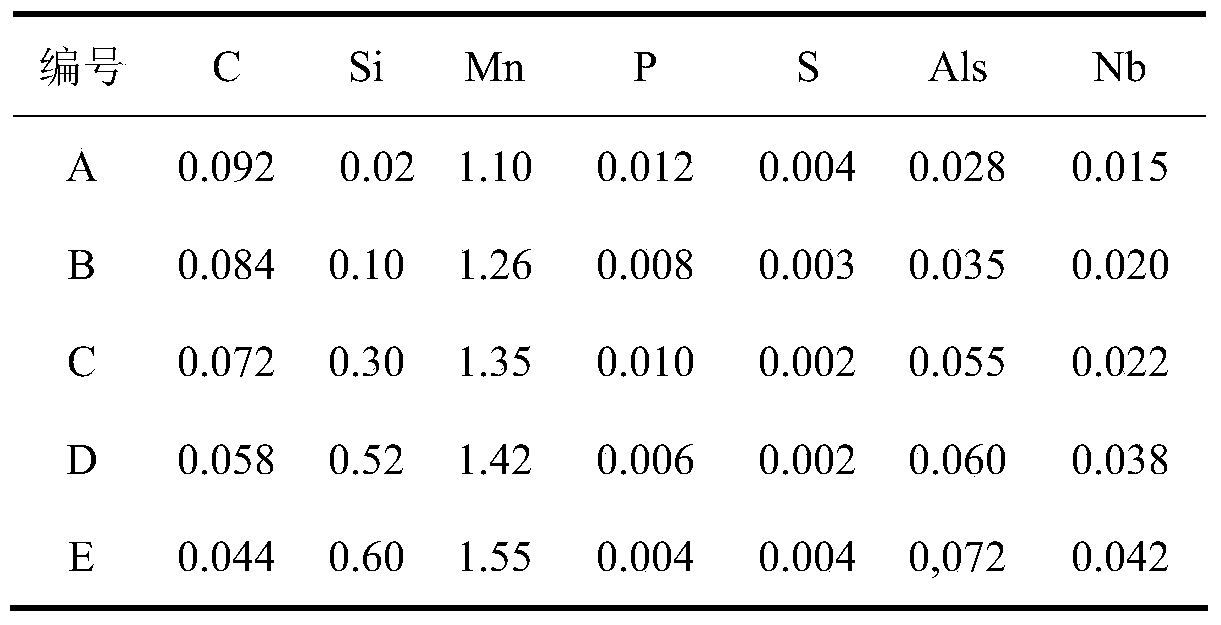

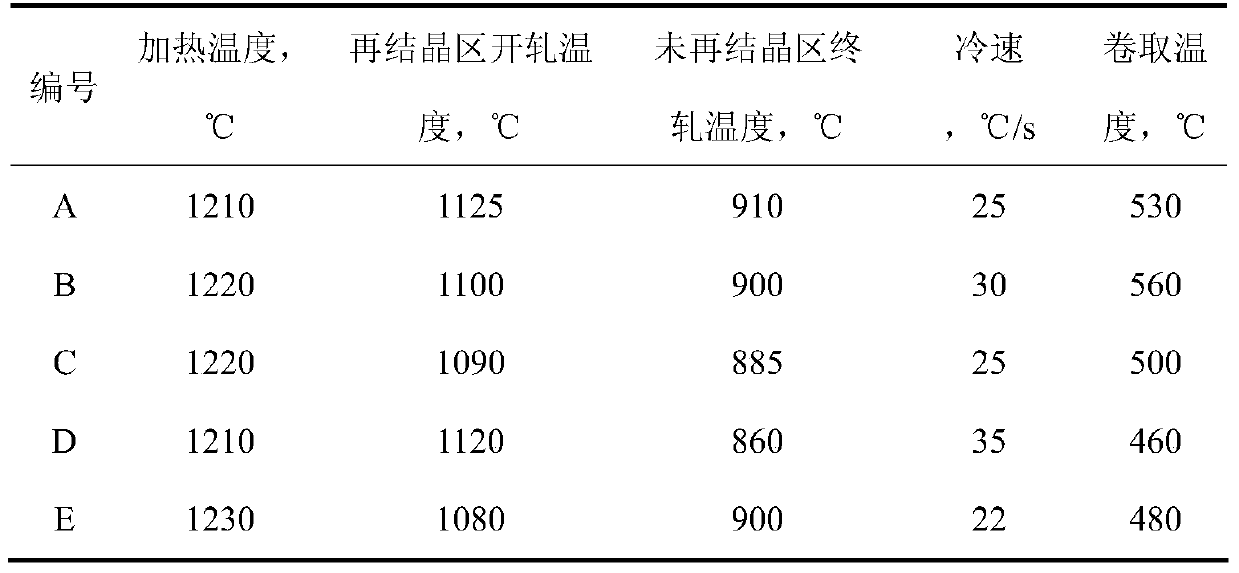

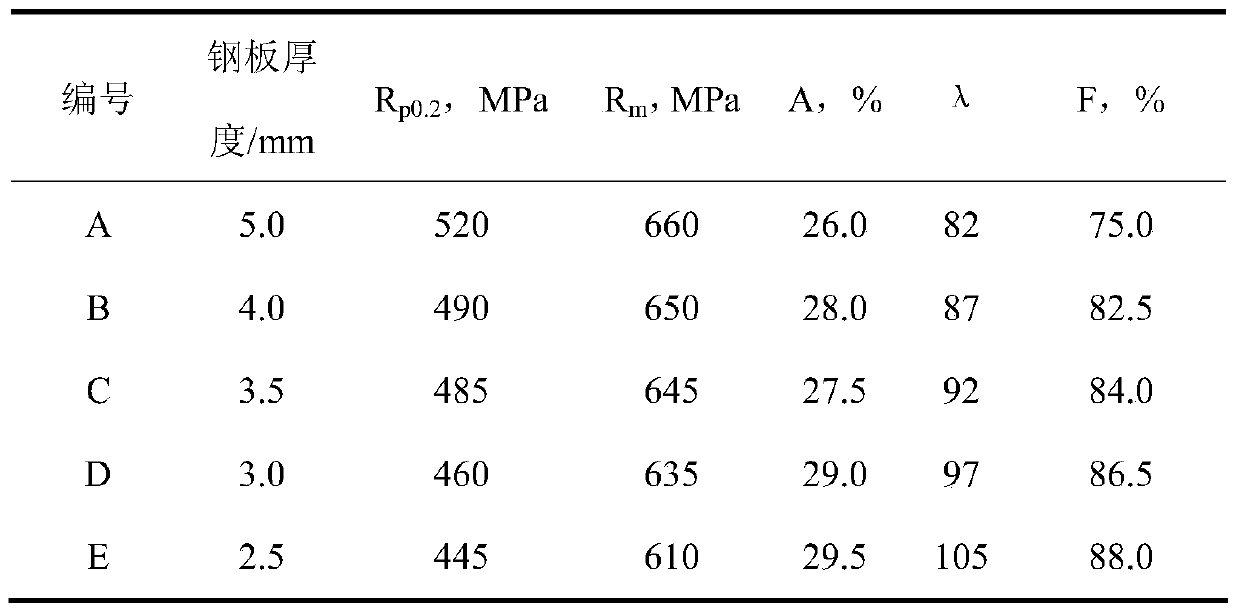

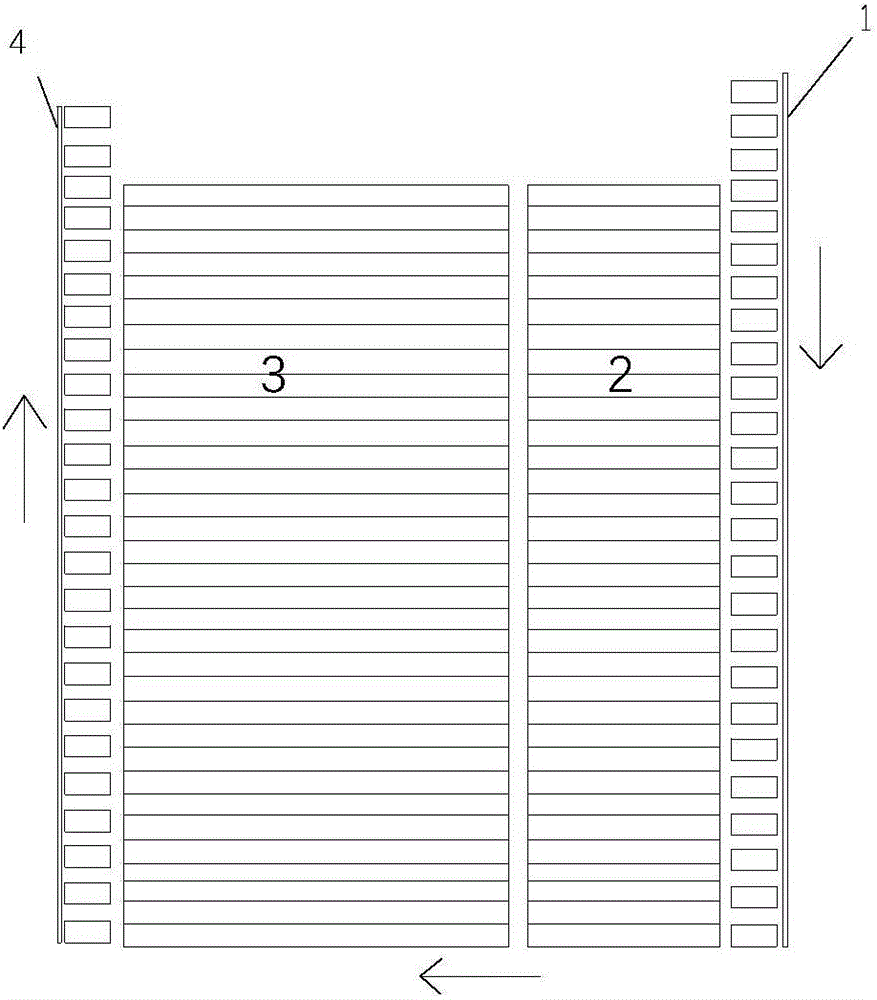

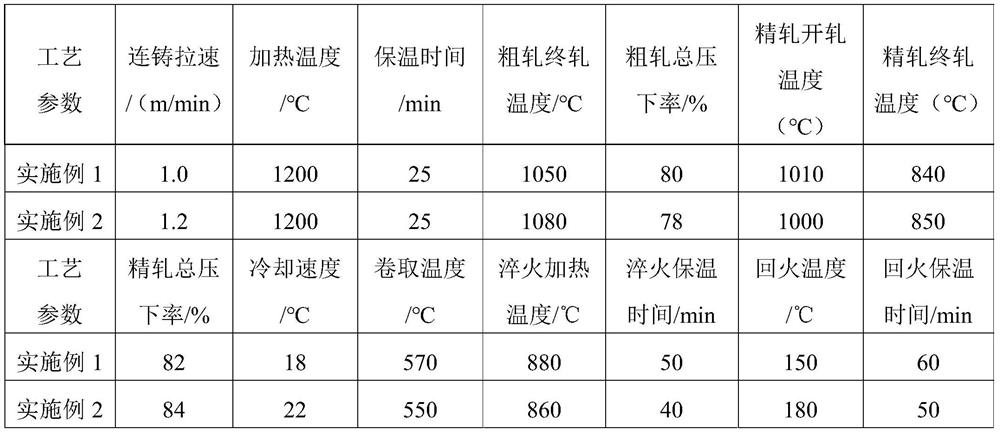

600 MPa-grade highly-chambered steel plate for automotive chassis and manufacturing method thereof

The invention provides a 600 MPa-grade highly-chambered steel plate for automotive chassis. Steel of the steel plate is composed of, in percentage by weight, 0.04-0.10% of C, Si smaller than 0.70%, 1.0-1.6% of Mn, 0.02-0.08% of Als, 0.01-0.05% of Nb, P smaller than 0.015%, S smaller than 0.005% and the balance Fe and inevitable impurities. The invention further provides a manufacturing method of the steel plate. The method comprises the steps of heating continuous casting sheet billets with the thickness ranging from 80 mm to 230 mm to 1220+ / -20 DEG C, and preserving the temperature for 1.8-3 hours; carrying out two-stage rolling, wherein the rolling temperature of the recrystallizing region is higher than 1050 DEG C, the thickness of intermediate billets ranges from 35 mm to 60 mm, the finish rolling temperature of the non-recrystallizing region ranges from 840 DEG C to 920 DEG C, and the thickness of finished products ranges from 2.0 mm to 6.0 mm; carrying out continuous laminar flow cooling after finish rolling, wherein the cooling rate is 20-40 DEG C / s and the coiling temperature ranges from 450 DEG C to 580 DEG C. According to the invention, the steel plate is high in alloy content and low in cost, the hot rolling process is simple, the rolling performance of the steel plate is uniform, and the matching performance between the strength and the hole chambering rate is good.

Owner:ANGANG STEEL CO LTD

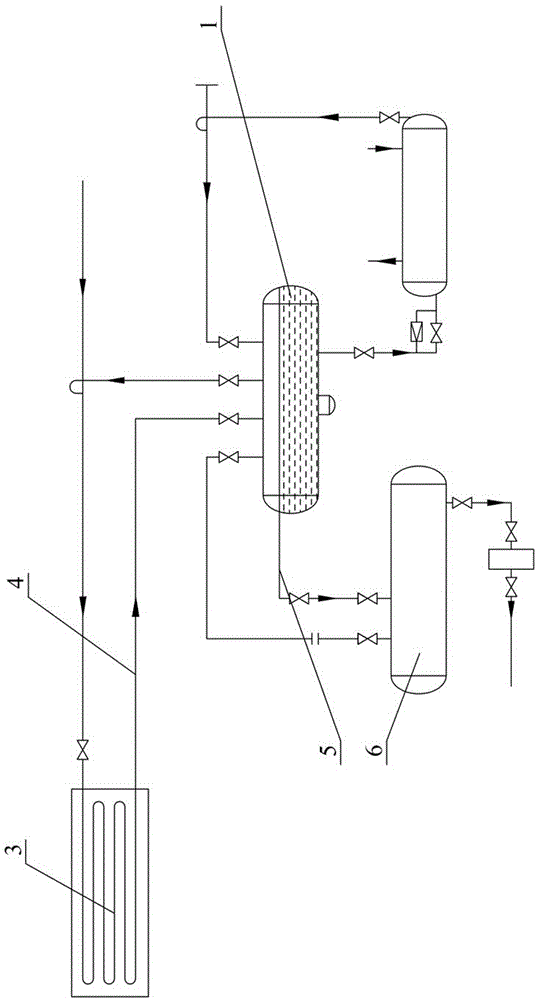

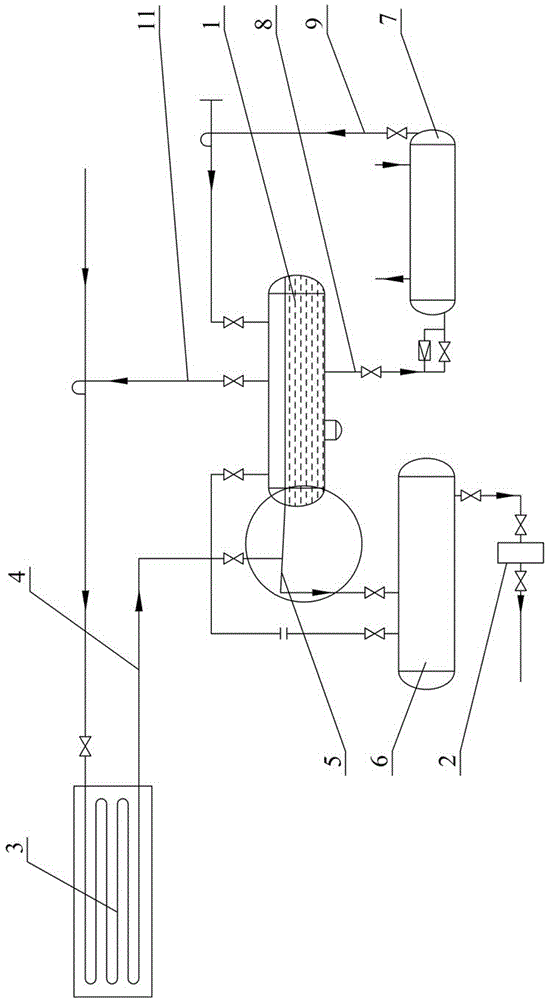

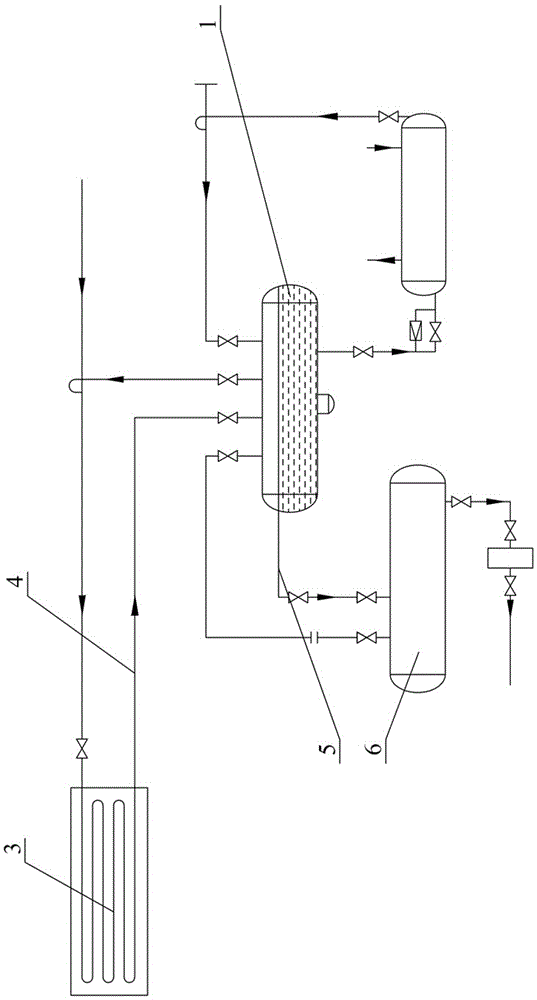

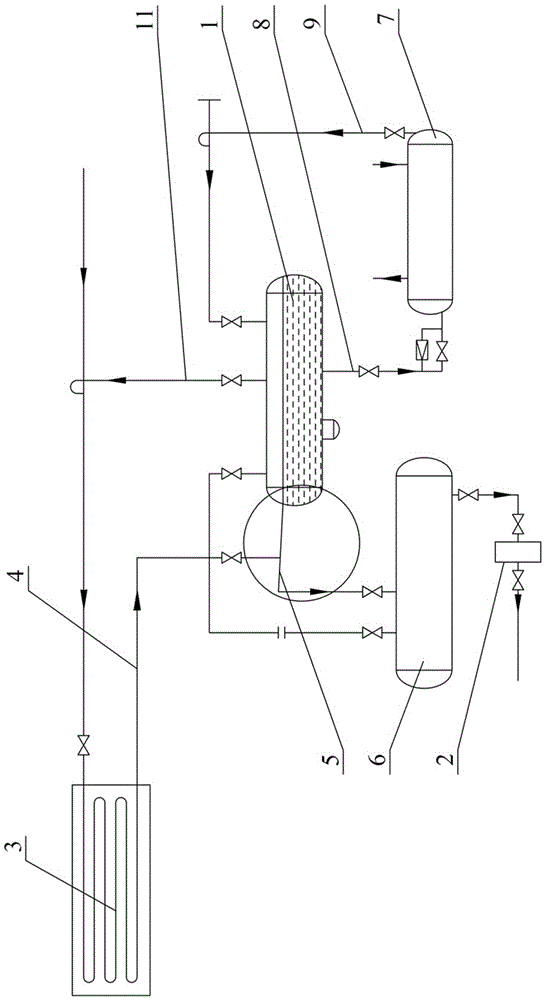

Thermal siphon oil cooling system

ActiveCN104567060AEfficient use ofSave energyMechanical apparatusCompression machines with non-reversible cycleThermodynamicsEngineering

The invention discloses a thermal siphon oil cooling system which comprises a thermal siphon liquid accumulator, a condenser, a high pressure liquid accumulator, a condenser liquid outlet pipe and a thermal siphon liquid accumulator overflow pipe, wherein an overflow port of the thermal siphon liquid accumulator and the high pressure liquid accumulator are communicated through the thermal siphon liquid accumulator overflow pipe. One end of the condenser liquid outlet pipe is connected with a liquid outlet of the condenser, and the other end of the condenser liquid outlet pipe is connected with the thermal siphon liquid accumulator overflow pipe. The thermal siphon oil cooling system has the advantages of being simple in structure, convenient to reform, safe, reliable and capable of saving energy.

Owner:SINOHYDRO BUREAU 8 CO LTD

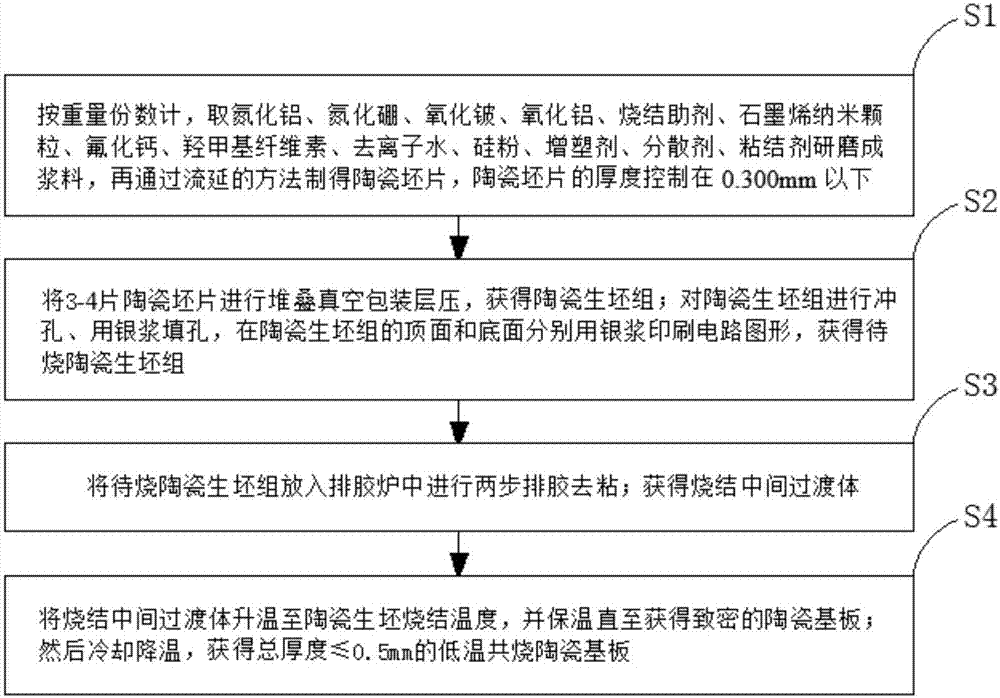

Forming and sintering method of low temperature co-fired ceramic substrate

The invention relates to a forming and sintering method of a low temperature co-fired ceramic substrate; the method comprises the steps of preparing ceramic body sheets; stacking the ceramic block sheets, packaging in vacuum, and laminating to obtain a ceramic green body set; punching the ceramic green body set, filling holes with silver paste and, printing circuit patterns on top and bottom surfaces of the ceramic green body set via silver paste to obtain a ceramic green body set to be fired; placing the ceramic green body set to be fired into a rubber removal furnace and performing two-step rubber removal and gluing to obtain a sintered intermediate transition part; heating the sintered intermediate transition part to ceramic green body sintering temperature, and holding the temperature until a compact ceramic substrate is obtained; cooling to obtain the low temperature co-fired ceramic substrate. Compared with the prior art, the method of the invention has the advantages that the combination of aluminum nitride, boron nitride and beryllium oxide decreases cost and maintains heat-dissipating performance; by adding graphene nanoparticles, heat can be transferred, and compactness of the ceramic substrate is also improved; the physiochemical prosperities of the ceramic substrate are optimized via hydroxymethyl cellulose.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

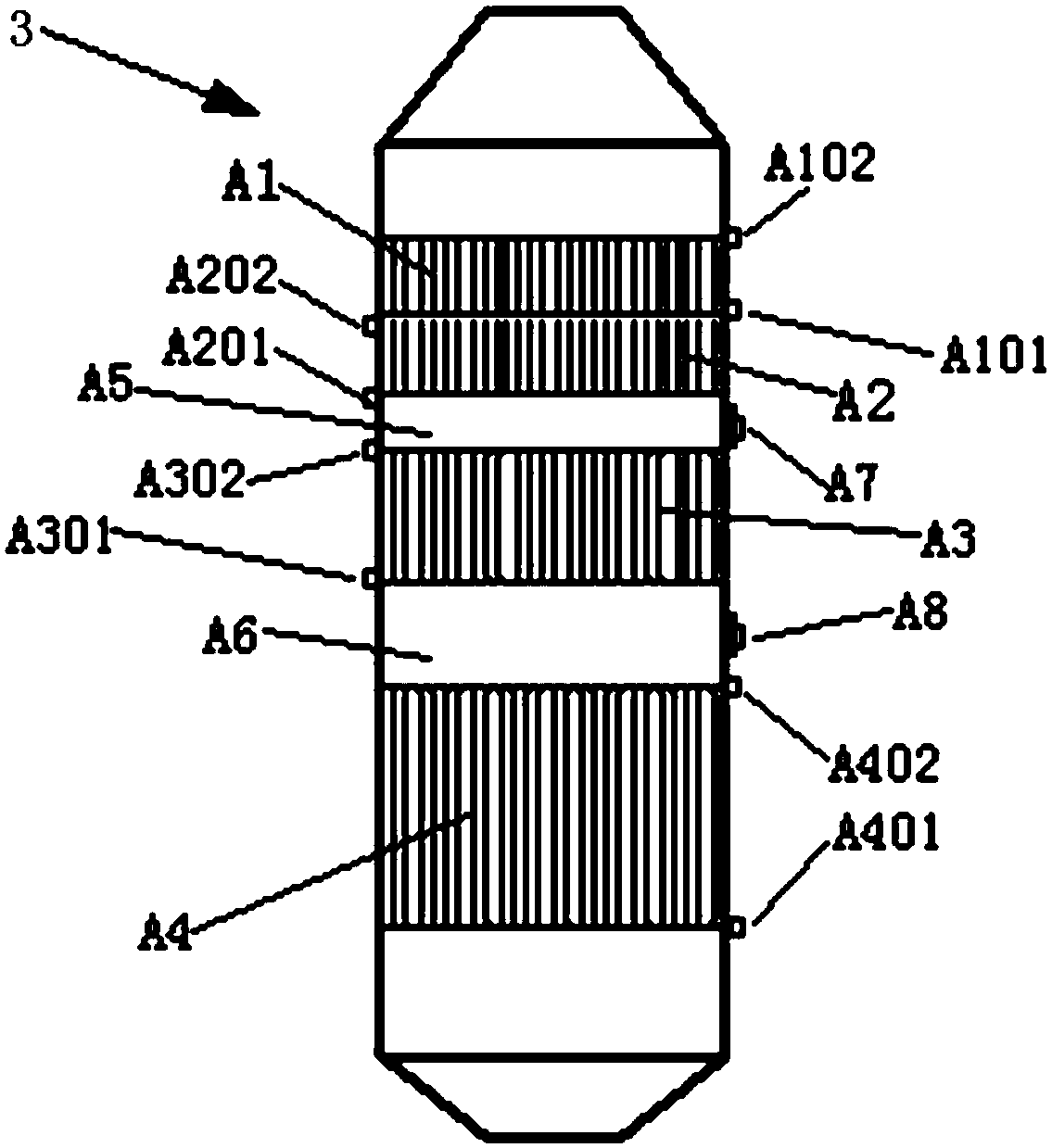

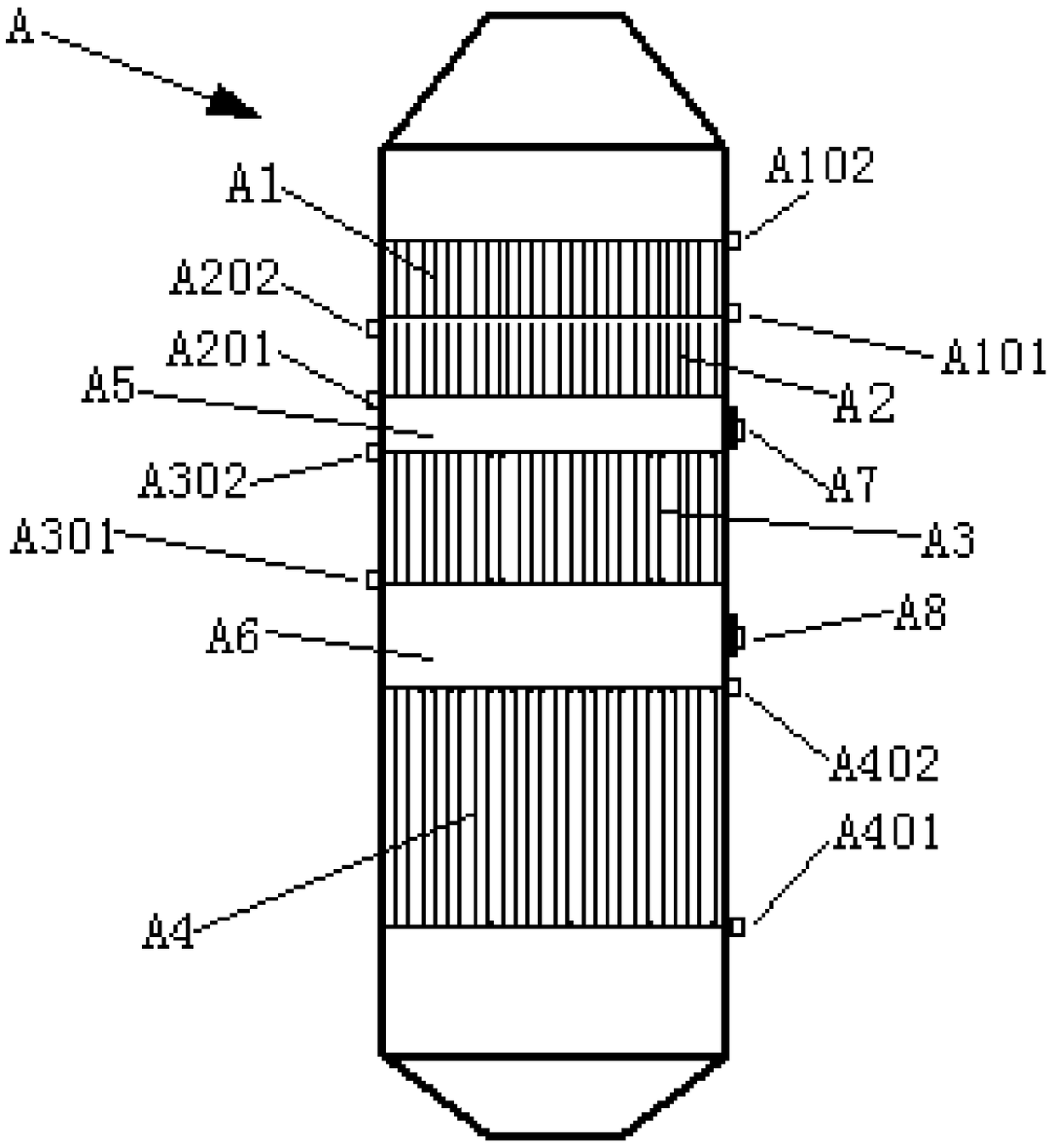

Novel active carbon analysis tower and active carbon analysis process

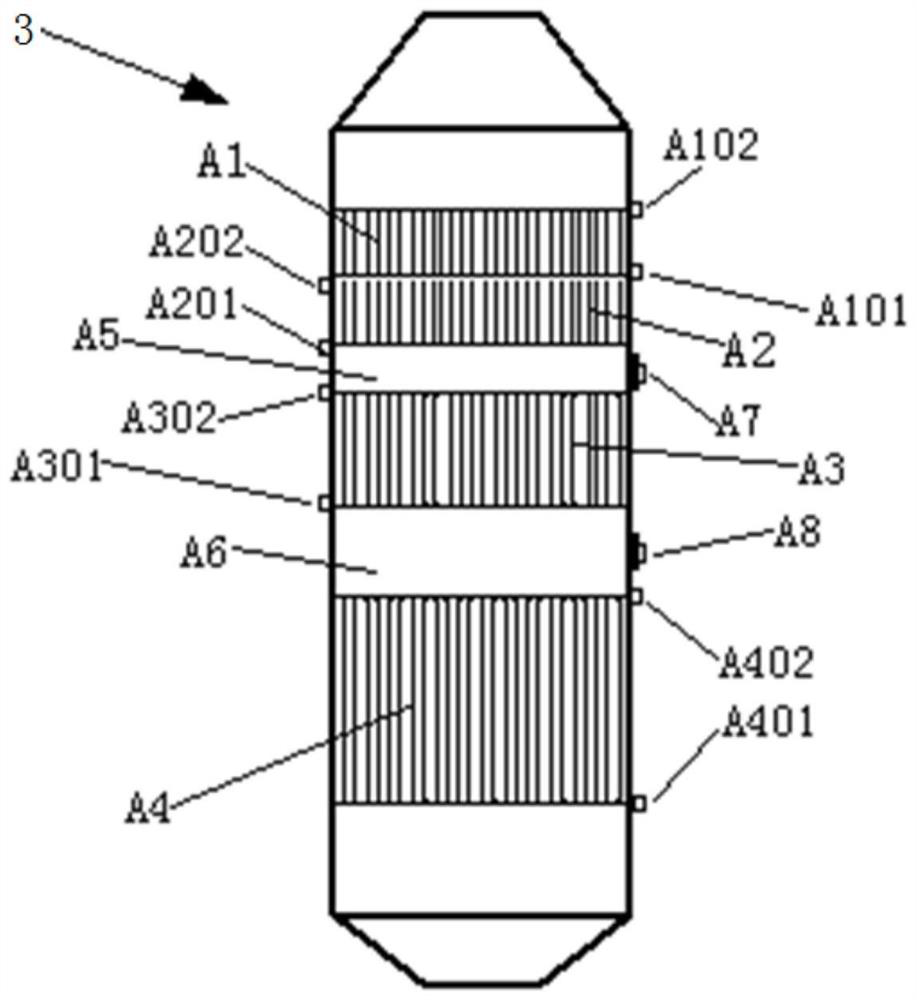

PendingCN108745331AReduce moisture contentFacilitate acid production processOther chemical processesDispersed particle separationActivated carbonDecomposition

The invention relates to a novel active carbon analysis tower and an active carbon analysis process. According to different decomposition temperatures of pollutants adsorbed by active carbon, the active carbon analysis tower (A) is provided with a preheating region (A1), a water vapor decomposition region (A2), a pollutant decomposition region (A3), a cooling region (A4), a first transitional section (A5) and a second transitional section (A6) from top to bottom, wherein a water vapor outlet (A7) is formed in the side wall of the first transitional section (A5); an SRG gas outlet (A8) is formed in the side wall of the second transitional section (A6). Water in the active carbon is separated in advance by a step-by-step heating method, so as to reduce the moisture content in SRG gas to create good conditions for normal operation of acid preparation and wastewater treatment procedures at the downstream.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Low-temperature cooling system

ActiveCN103779033ASimple cooling processReduce usageSuperconducting magnets/coilsLiquid nitrogen containerManufacturing technology

The invention discloses a low-temperature cooling system and belongs to the technical field of design and manufacture of medical apparatus and instruments. The invention provides a low-temperature cooling system through which the cost can be obviously reduced in the process of cooling a superconducting magnet in a temperature area from 300K to 4.2K. The low-temperature cooling system comprises a low-temperature refrigerated container, a low-temperature refrigerating unit, a liquid nitrogen container with a mounting channel, a cold shield with a perforation, and a 300K container with a connecting flange, wherein the liquid nitrogen container is positioned in the cold shield; the cold shield is positioned in the 300K container; the low-temperature refrigerating unit comprises a primary refrigerating unit, a secondary refrigerating unit and a primary hot link; the low-temperature refrigerating unit is arranged in the mounting channel through a top wall of the low-temperature refrigerated container; the secondary refrigerating unit is positioned in the mounting channel; the low-temperature cooling system also comprises a heat exchange cold guiding device positioned at the middle lower part of the mounting channel; the heat exchange cold guiding device is connected to the tail end of the secondary refrigerating unit of the low-temperature refrigerating unit.

Owner:ALLTECH MEDICAL SYST

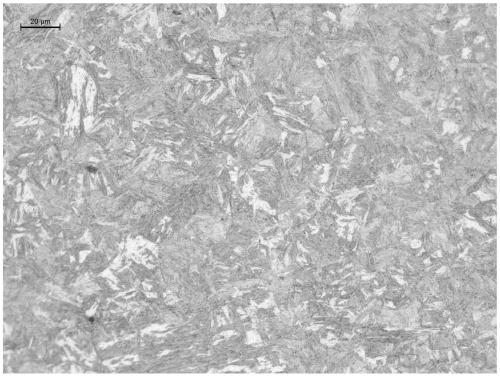

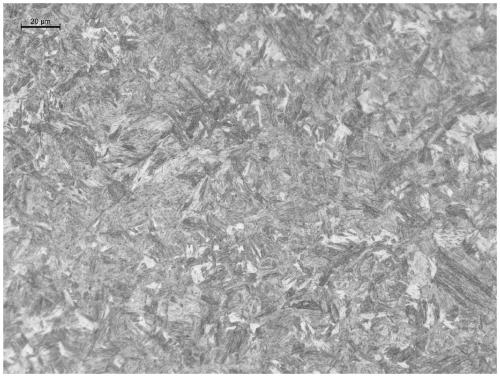

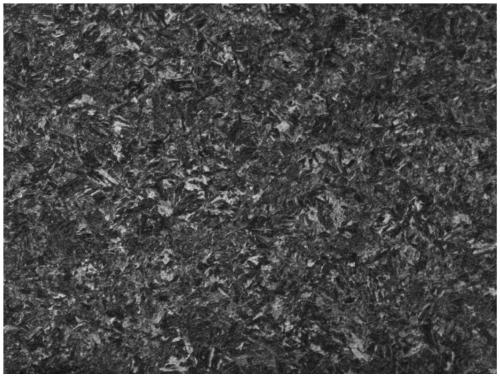

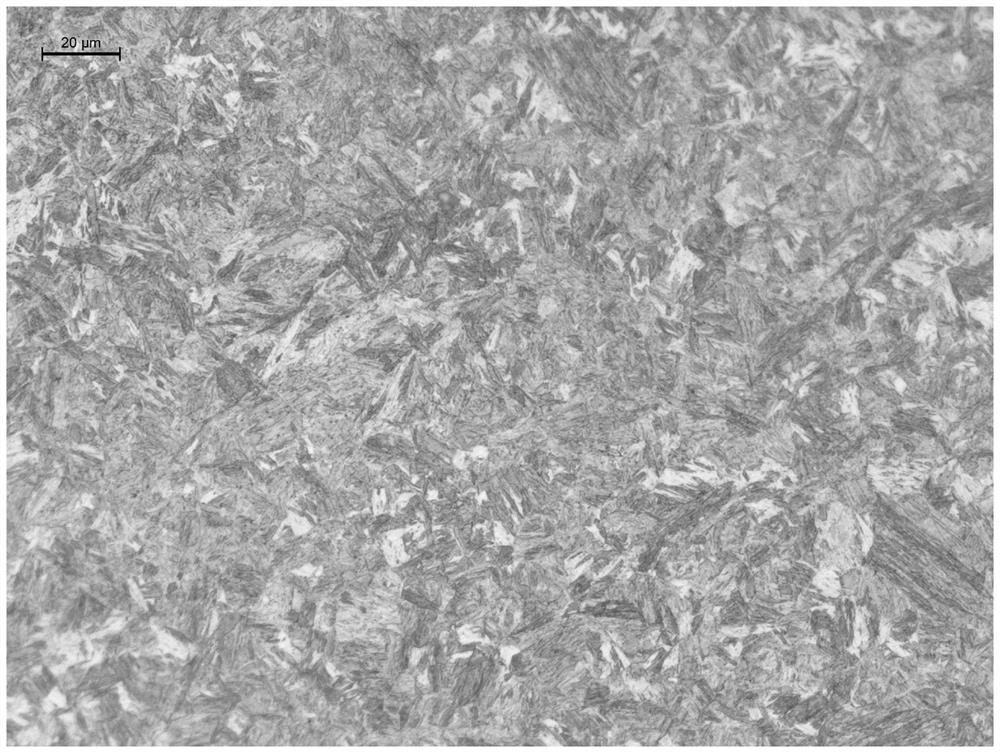

Acid corrosion resistance martensite wear-resisting steel plate and manufacturing method thereof

ActiveCN111575581AGuaranteed corrosion resistanceImprove mechanical propertiesFurnace typesHeat treatment furnacesAcid corrosionMartensite

The invention discloses an acid corrosion resistance martensite wear-resisting steel plate. The steel plate is prepared from, by mass, 0.14-0.22 wt% of C, 0.30-0.60 wt% of Si, 0.30-1.00 wt% of Mn, 0.010-0.020 wt% of Ti, 0.02-0.04 wt% of Nb, 0.50-1.0 wt% of Ni, 0.20-0.50 wt% of Cu, 0.9-1.3 wt% of Cr, 0.08-0.12 wt% of Sb, 0.0010-0.0020 wt% of B, 0-0.003 wt% of S and 0-0.012 wt% of P. The acid corrosion resistance martensite wear-resisting steel plate can achieve the purposes of good hardness, plasticity, wear resistance and corrosion resistance of the steel plate.

Owner:湖南华菱涟源钢铁有限公司 +3

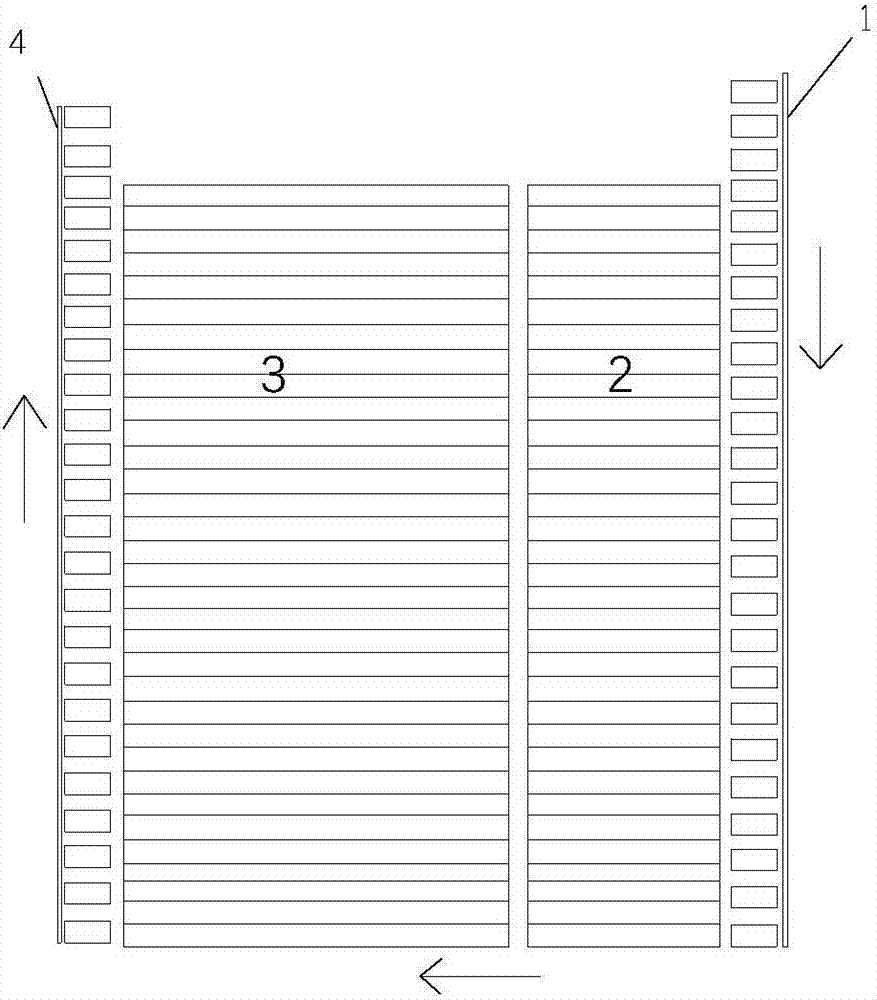

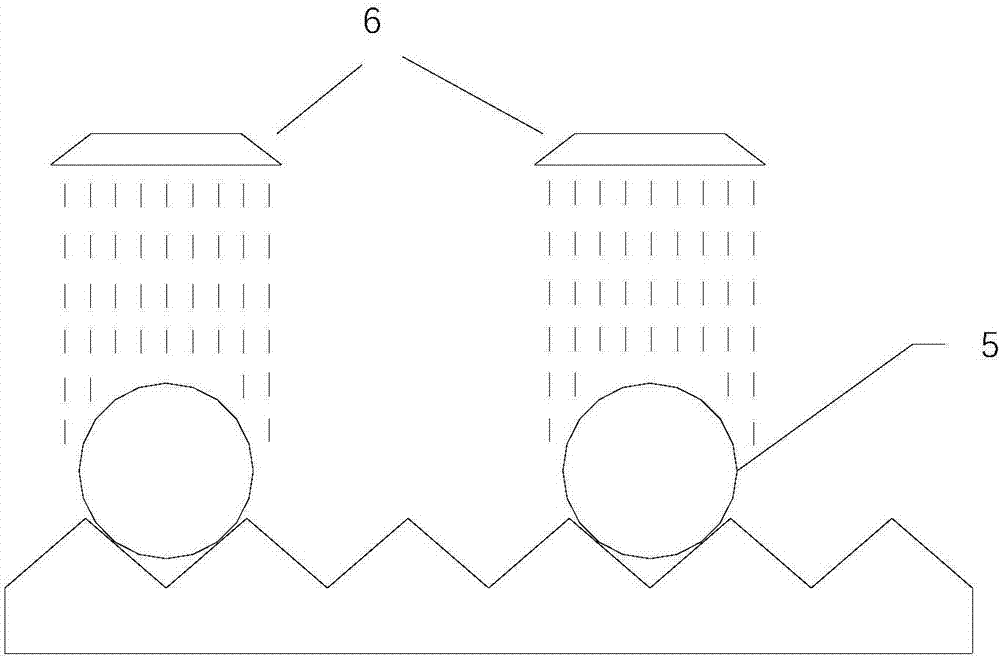

Control method for bearing steel bar network carbide and device for implementing method

ActiveCN105817487AInhibition formationReduce manufacturing costTemperature control deviceCooling bedsCarbideSlow cooling

The invention discloses a control method for bearing steel bar network carbide and a device for implementing the method. The control method comprises the following steps that the finish rolling temperature of a bearing steel bar with the diameter being phi 20-60 mm is controlled to be 940-1000 DEG C, and the cooling speed of the bearing steel bar is controlled through a double-cooling-area cooling mode after rolling; double cooling areas include the cooling bed quick water cooling area and the cooling bed re-reddening slow cooling area; during the process in the cooling bed quick water cooling area, after rolling, the high-temperature bearing steel bar is fed into the cooling bed quick water cooling area from a cooling bed entry table, and the surface temperature of the bearing steel bar is controlled to be rapidly decreased to 400-450 DEG C through water cooling; during the process in the cooling bed re-reddening slow cooling area, when the temperature of the core part of the bearing steel bar fed into the re-reddening slow cooling area is higher than the surface temperature, heat diffuses from interior to exterior, the bearing steel bar starts to re-redden, the surface temperature is raised to 600-650 DEG C, and then the bearing steel bar is slowly cooled to 150-300 DEG C in the air. The structure grade of the network carbide is controlled within the 1.0 grade.

Owner:SHANDONG IRON & STEEL CO LTD

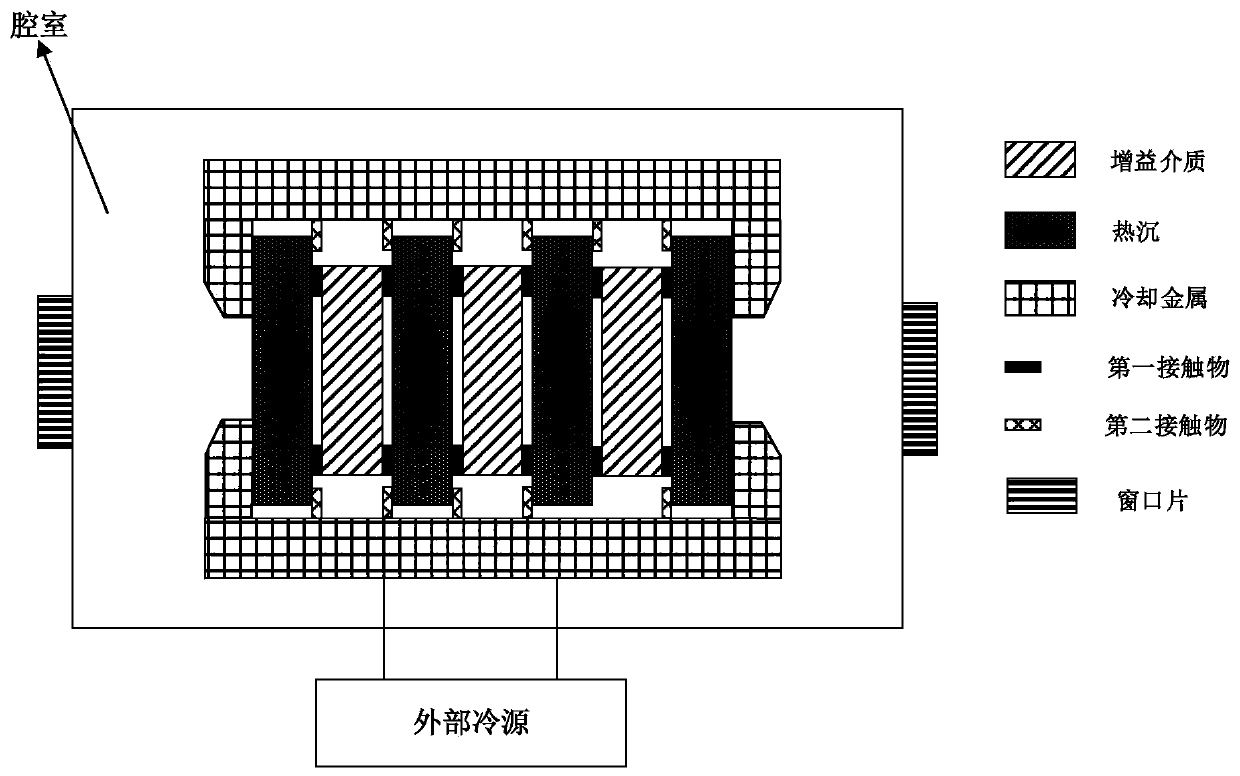

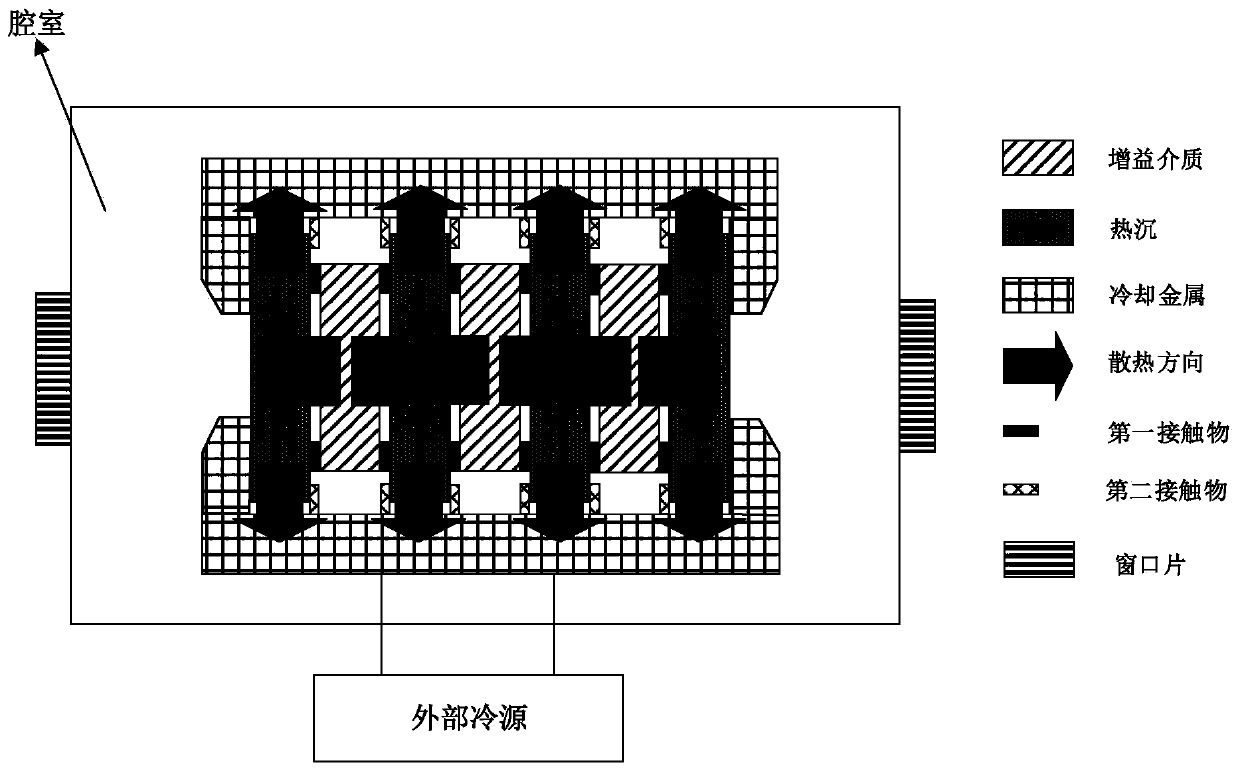

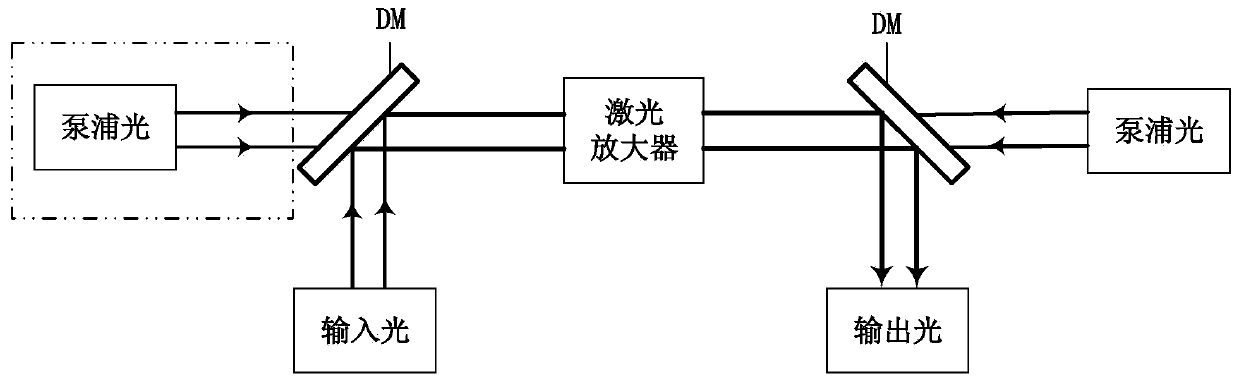

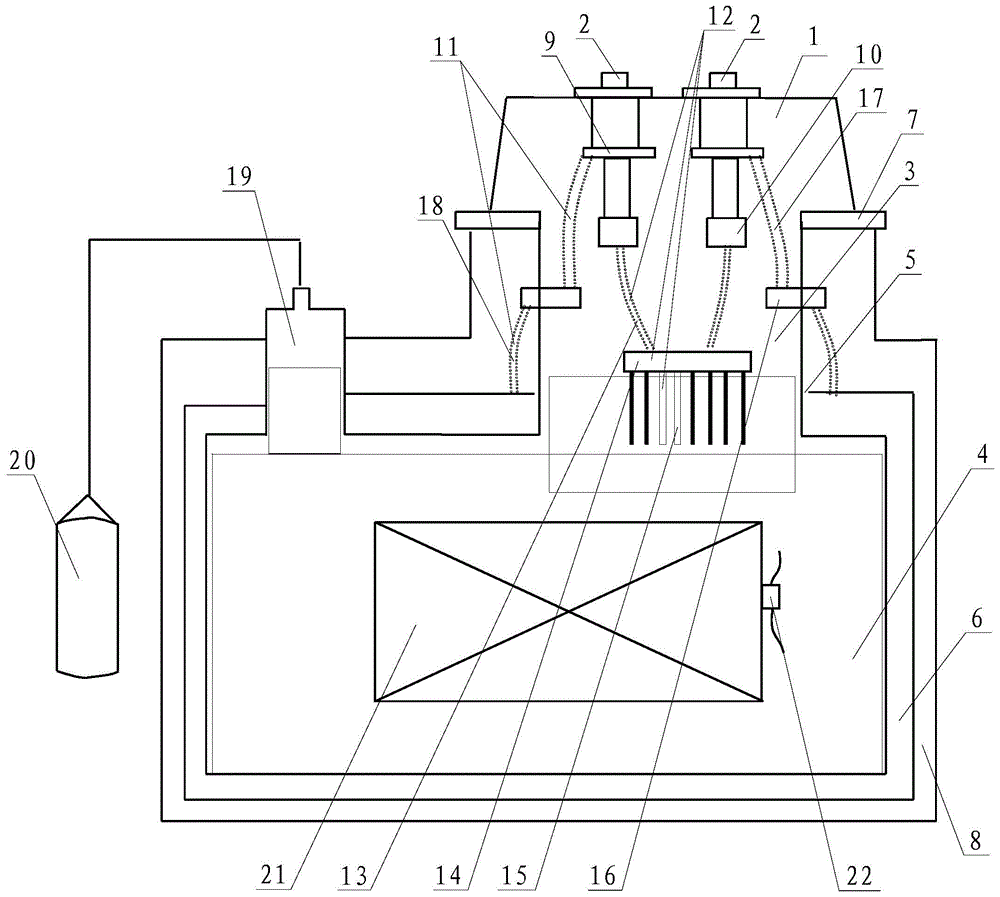

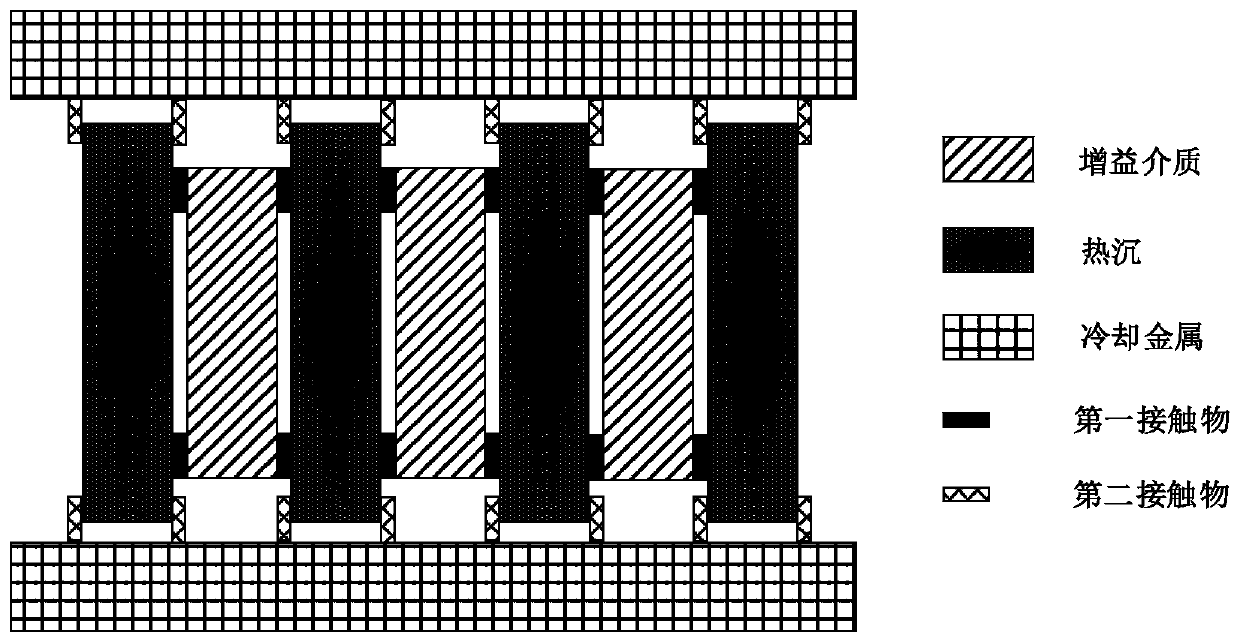

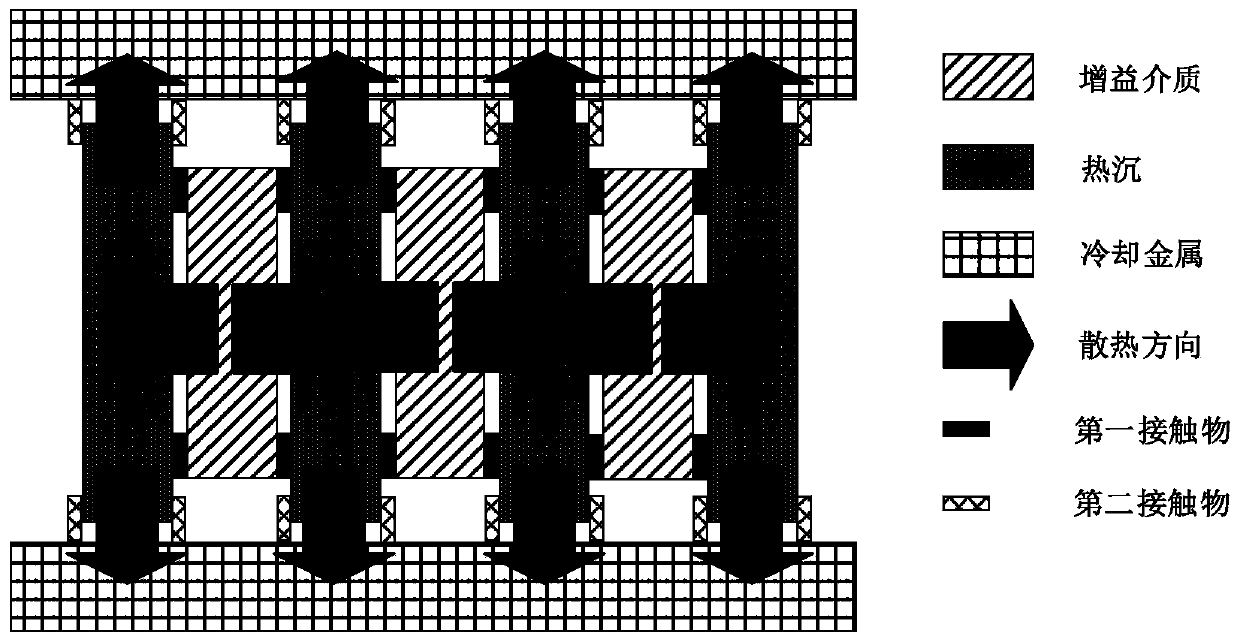

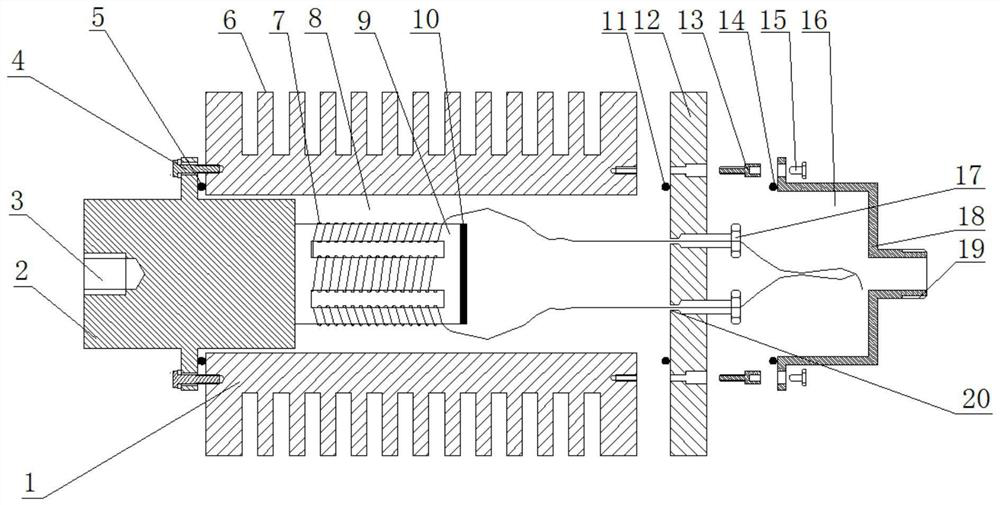

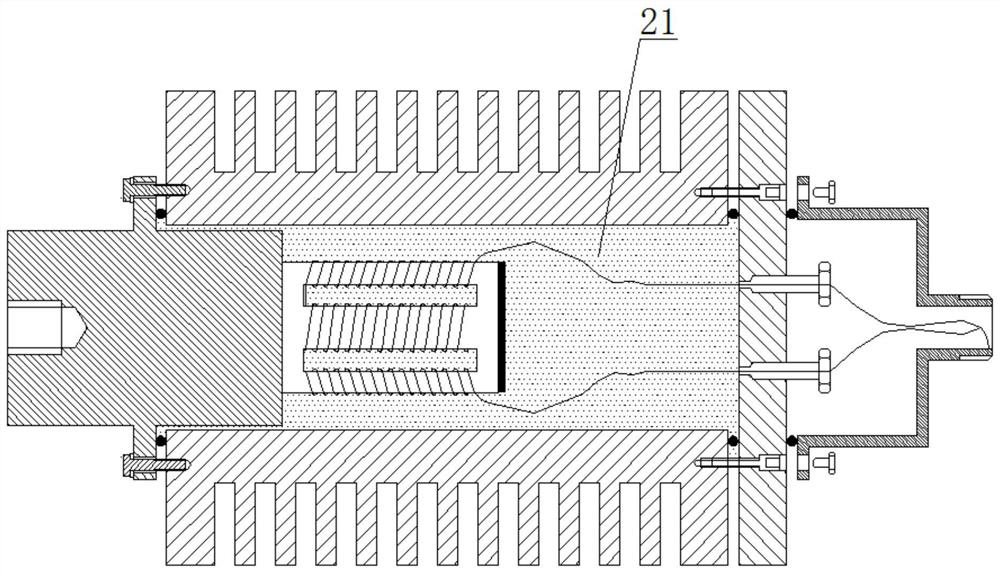

Double-sided conduction cooling multi-sheet laser amplifier and system

InactiveCN111431020ASimple cooling processCompact structureActive medium shape and constructionLaser cooling arrangementsConduction coolingGain

The embodiment of the invention provides a double-sided conduction cooling multi-sheet laser amplifier and a system. The amplifier comprises a laser head, a cavity and an external cold source, and thelaser head comprises a gain medium, a heat sink, a cooling metal, a first contact object and a second contact object. The gain medium and the heat sink are both sheet-shaped and are separately arranged in parallel at intervals, the cooling metal is arranged at the peripheries of the gain medium and the heat sink, and the cooling temperature is constant. The centers of the gain medium and the heatsink are coaxial, and the plane of the gain medium is vertical to the central axis. The edge of the gain medium is connected with the edge of the heat sink through the first contact object, and the edges of the two surfaces of the heat sink are connected with the inner wall of the cooling metal through the second contact object. The double-sided conduction cooling multi-slice laser amplifier andthe system provided by the embodiment of the invention have the advantages that the gain medium has no special requirements for gradual change, interval or gradient doping and the like, the cooling action process is simple, the structure is compact, and the heat dissipation effect is good, and the high-power output of a multi-slice laser is facilitated.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Atmospheric corrosion resistant martensitic wear-resistant steel plate and manufacturing method thereof

The invention belongs to the technical field of ferrous metallurgy, and particularly relates to an atmospheric corrosion resistant martensitic wear-resistant steel plate. The atmospheric corrosion resistant martensitic wear-resistant steel plate comprises the following components including, by mass, larger than or equal to 0.14wt% and smaller than or equal to 0.22wt% of C, larger than or equal to0.30wt% and smaller than or equal to 0.60wt% of Si, larger than or equal to 0.30wt% and smaller than or equal to 1.00wt% of Mn, larger than or equal to 0.010wt% and smaller than or equal to 0.020wt% of Ti, larger than or equal to 0.02wt% and smaller than or equal to 0.04wt% of Nb, larger than or equal to 0.50 wt% and smaller than or equal to 1.0wt% of Ni, larger than or equal to 0.20 wt% and smaller than or equal to 0.50wt% of Cu, larger than or equal to 3.4 wt% and smaller than or equal to 4.0wt% of Cr, larger than or equal to 0.0010 wt% and smaller than or equal to 0.0020wt% of B, larger than 0 and smaller than or equal to 0.003wt% of S, larger than 0 and smaller than or equal to 0.012wt% of P and the balance iron and other inevitable impurities, wherein the atmospheric corrosion resistant martensitic wear-resistant steel plate can solve the problems of hardness, plasticity, toughness, wear resistance and corrosion resistance of the steel plate.

Owner:湖南华菱涟源钢铁有限公司 +3

Manufacturing method of structural steel

The invention discloses a manufacturing method of structural steel; through a controlled rolling and controlled cooling process and by utilizing the equilibrium relationship between shape change and phase change, carbon and boron in ferrite diffuse into austenite in the phase change incubation period under the condition that the phase transformation nucleation points are increased, so that the phase change period can be shortened. The boron-contained structural steel contains the following chemical components by weight: 0.08-0.20% of C, 0.10-0.30% of Si, 0.80-1.50% of Mn, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.0008-0.0030% of B, and the balance of Fe and inevitable impurities. The boron-contained structural steel obtained through the invention is homogeneous in structure, small in grain and good in obdurability.

Owner:吴雪

A kind of steel for ultra-high strength sucker rod and its manufacturing method

ActiveCN105624562BSimple cooling processImprove corrosion resistanceComposite nanoparticlesUltimate tensile strength

Owner:CENT IRON & STEEL RES INST +1

High-manganese pipeline steel and preparation method thereof

The invention provides high-manganese pipeline steel and a preparation method thereof. The high-manganese pipeline steel is prepared from the following ingredients in percentage by weight: 0.4 to 0.7percent of C, 13 to 17 percent of Mn, 0.5 to 0.8 percent of Mo, 0.9 to 1.1 percent of Cr, 0.2 to 0.4 percent of Si, less than or equal to 0.010 percent of P, less than or equal to 0.003 percent of S,0.02 to 0.03 percent of Al, 0.02 to 0.03 percent of Nb, 0.03 to 0.06 percent of V and the balance of Fe and unavoidable impurities. The preparation method comprises the following steps of performing melting, casting and blank forming according to the high-manganese pipeline steel ingredients proportion; heating a cast blank to 1,200 to 1,250 DEG C; performing heat insulation for 1 to 2 hours; performing alloy element complete solid solution; performing sufficient tissue austenitizing; rolling the cast blank subjected to heat insulation; controlling the initial rolling and final rolling temperature and press-down quantity; cooling the materials to the room temperature after the rolling completion; obtaining the high-manganese austenitizing pipeline steel. The method has the advantages thatthe process is simple; the prepared high-manganese pipeline steel has ultralow yield ratio, higher tensile intensity, uniform elongation rate and excellent anti-corrosion performance, and is suitablefor being used as an oil gas conveying pipeline material in an extreme environment.

Owner:NORTHEASTERN UNIV

A flue gas purification device for improving the utilization rate of waste heat and denitration rate and using method thereof

ActiveCN108939807BReduce pollutionEfficient use ofGas treatmentDispersed particle separationActivated carbonThermodynamics

According to a trend of flue gas, the flue gas purification device for improving waste heat utilization rate and denitration rate includes a primary adsorption column and a secondary adsorption columndisposed downstream the primary adsorption column. An original flue gas conveying pipeline is connected to a flue gas inlet of the primary adsorption column; a flue gas outlet of the primary adsorption column is connected to a flue gas inlet of the secondary adsorption column through a first pipeline; the device further comprises an analytical tower; a heating section and a cooling section are disposed on the analytical tower; the lower part of the heating section is provided with a heating section gas inlet, and the upper part of the heating section is provided with a heating section gas outlet; and the heating section gas outlet of the analytical tower is connected to the flue gas inlet of the secondary adsorption column by a second pipeline. The device introduces a part of exhausted hot air after heat exchange with to-be-analyzed activated carbon into the flue gas inlet of the secondary adsorption column, and on one hand, the concentration of exhausted SO<2> is removed, and simultaneously flue gas at the inlet of the secondary adsorption column is heated to improve the temperature of the flue gas.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

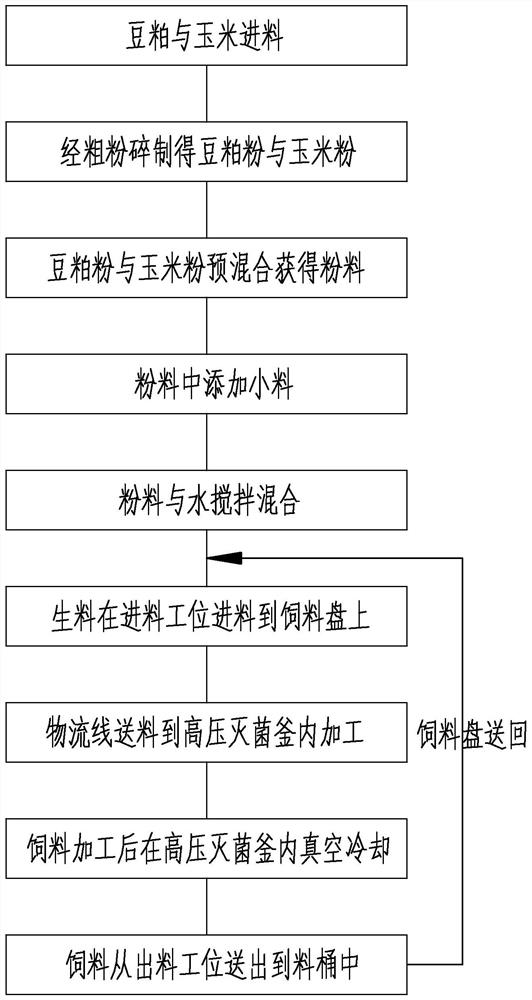

High-pressure sterilization type artificial feed production process applied to industrial silkworm breeding

PendingCN114258982AIncrease productivityEasy to digestFood processingAnimal feeding stuffFeed processingProcess engineering

The invention discloses a high-pressure sterilization type artificial feed production process applied to industrial silkworm breeding, which comprises the following steps: (1) raw material treatment: crushing raw materials, and mixing the crushed raw materials to obtain powder; (2) feed processing: mixing and stirring the powder and water, and performing high-pressure sterilization processing to obtain the feed; and (3) cooling the feed. A systematic and continuous production method is designed and comprises three coherent steps of raw material treatment, processing and feed cooling, uniformly mixed powder is obtained after raw material treatment, the powder and water are stirred and mixed, the feed is processed and cooled in a high-pressure sterilization mode, the purpose of large-scale, systematic and continuous feed production is achieved, and the production efficiency is improved. And the production efficiency is obviously improved. The high-pressure sterilization mode can achieve sterilization and disinfection effects on the feed, the content of bacteria on the surface of the feed is controlled, silkworms are easy to digest after eating the feed, and the illness probability is remarkably reduced.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

A kind of high manganese pipeline steel and its preparation method

A kind of high manganese pipeline steel and its preparation method of the present invention. The components of the high manganese pipeline steel in weight percentage are C 0.4~0.7%, Mn 13~17%, Mo 0.5~0.8%, Cr 0.9~1.1%, Si 0.2~ 0.4%, P≤0.010%, S≤0.003%, Al 0.02~0.03%, Nb 0.02~0.03%, V 0.03~0.06%, the balance is Fe and unavoidable impurities. The steps of the production method are: smelting and casting the high manganese pipeline steel into a billet according to the composition ratio, heating the billet to 1200-1250°C, and holding it for 1-2 hours to completely dissolve the alloy elements and fully austenitize the structure; The final cast slab is rolled, and the opening and final rolling temperatures and reductions are controlled. After the rolling is completed, it is cooled to room temperature to obtain high manganese austenitic pipeline steel. The process of this method is simple, and the prepared high-manganese pipeline steel has extremely low yield ratio, high tensile strength, uniform elongation and excellent corrosion resistance, and is suitable as an oil and gas transmission pipeline material in extreme environments.

Owner:NORTHEASTERN UNIV LIAONING

cryogenic cooling system

ActiveCN103779033BSimple cooling processReduce usageSuperconducting magnets/coilsLiquid nitrogen containerManufacturing technology

The invention discloses a low-temperature cooling system and belongs to the technical field of design and manufacture of medical apparatus and instruments. The invention provides a low-temperature cooling system through which the cost can be obviously reduced in the process of cooling a superconducting magnet in a temperature area from 300K to 4.2K. The low-temperature cooling system comprises a low-temperature refrigerated container, a low-temperature refrigerating unit, a liquid nitrogen container with a mounting channel, a cold shield with a perforation, and a 300K container with a connecting flange, wherein the liquid nitrogen container is positioned in the cold shield; the cold shield is positioned in the 300K container; the low-temperature refrigerating unit comprises a primary refrigerating unit, a secondary refrigerating unit and a primary hot link; the low-temperature refrigerating unit is arranged in the mounting channel through a top wall of the low-temperature refrigerated container; the secondary refrigerating unit is positioned in the mounting channel; the low-temperature cooling system also comprises a heat exchange cold guiding device positioned at the middle lower part of the mounting channel; the heat exchange cold guiding device is connected to the tail end of the secondary refrigerating unit of the low-temperature refrigerating unit.

Owner:ALLTECH MEDICAL SYST

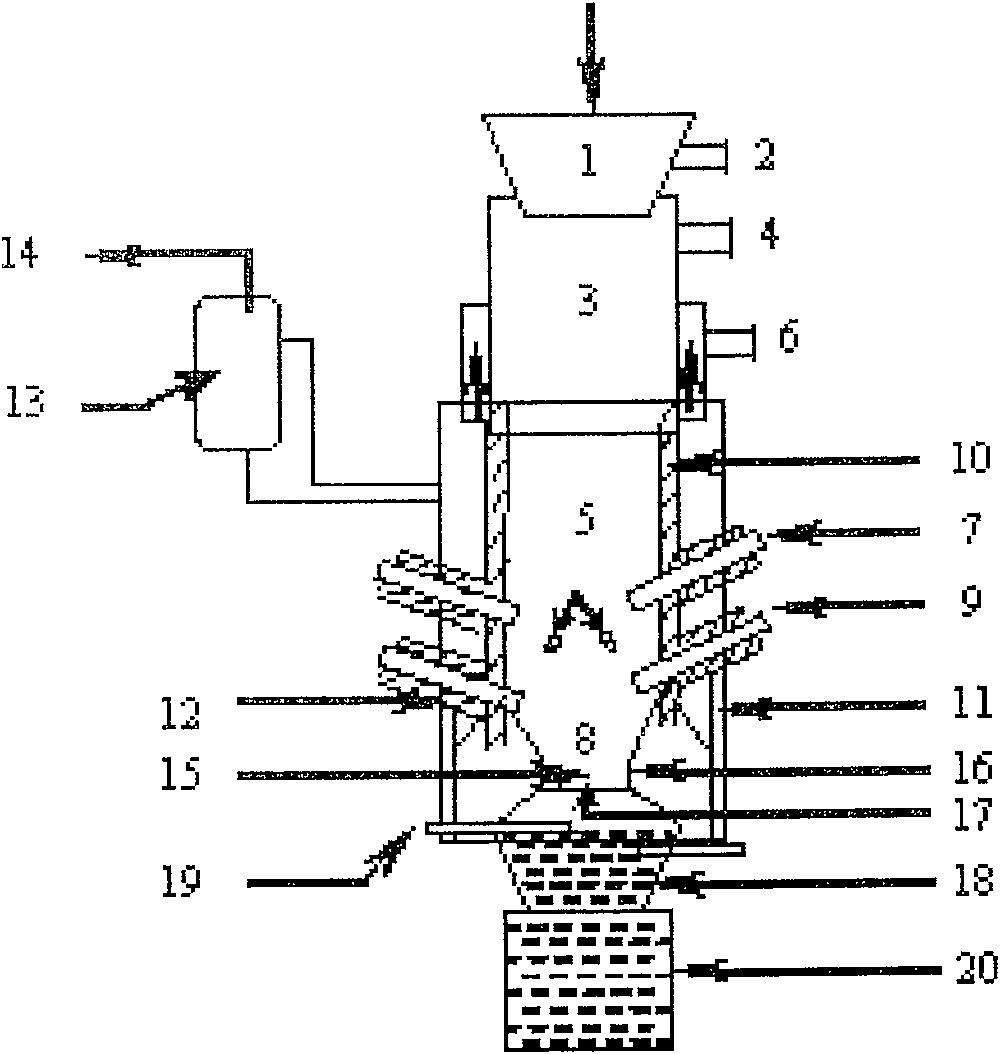

Integration installation for producing synthesis gas from coal with high volatile constituent

InactiveCN100560696CEliminates direct cooling processLess investmentCombustible gas productionSyngasResource utilization

This invention discloses an integrated apparatus for producing synthesis gas from high-volatile coal. The apparatus is composed of an upper drying and retorting section, a middle conversion and gasification section, and a lower liquid slag discharge section. The upper drying and retorting unit comprises: a sealed coal container set at the top, a pyrolysis coal gas outlet at the upper part, and a synthesis gas outlet at the middle part. The conversion section has a pyrolysis coal gas inlet at the bottom, and is connected with the retorting section and the gasification unit at the top and bottom, respectively. The conversion and gasification section has refractory lining inner wall and water jacket outer wall, and the water jacket comprises: a cooling water inlet, a cooling water outlet, and a liquid / solid slag discharge structure. The slag discharge section comprises: an upper slag discharge port, a middle slag-quenching chamber and a lower sealed slag hopper. The apparatus integrates pyrolysis, gasification and pyrolysis coal gas conversion to produce synthesis gas, and has such advantages as high resource utility, little pollution, and high profit.

Owner:山西中元煤洁净技术有限公司

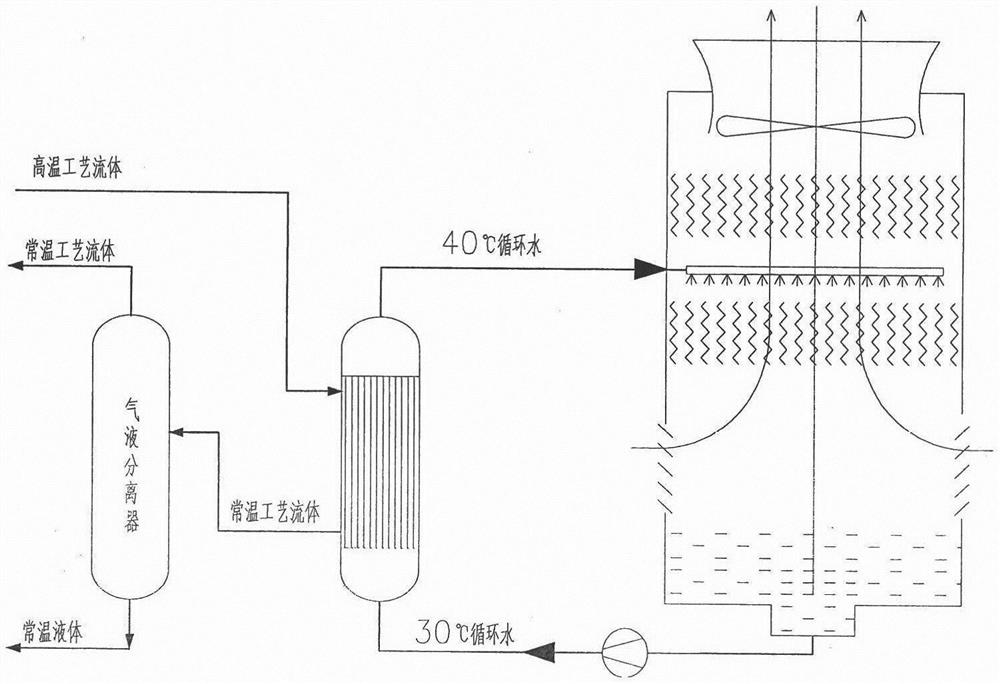

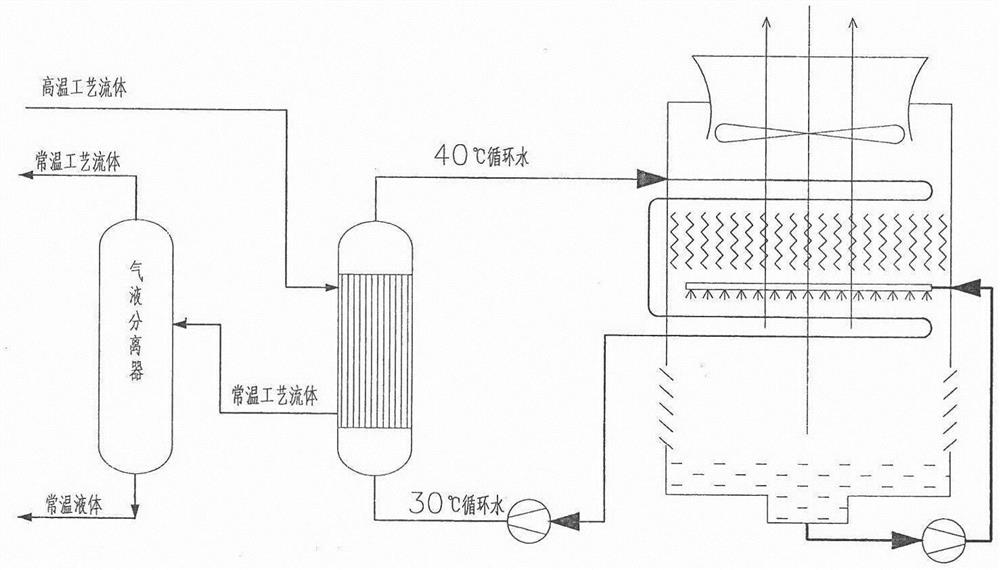

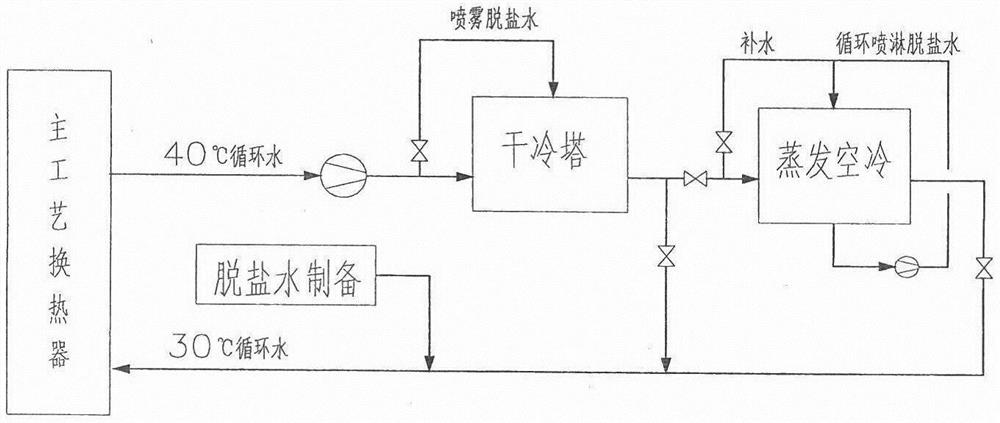

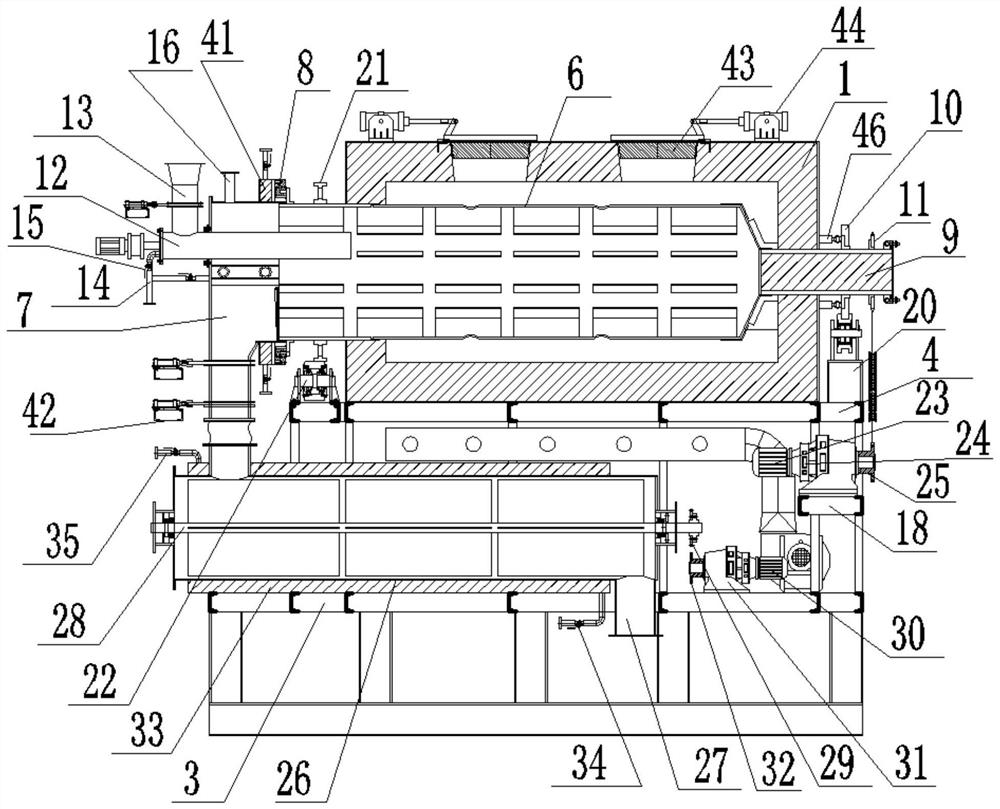

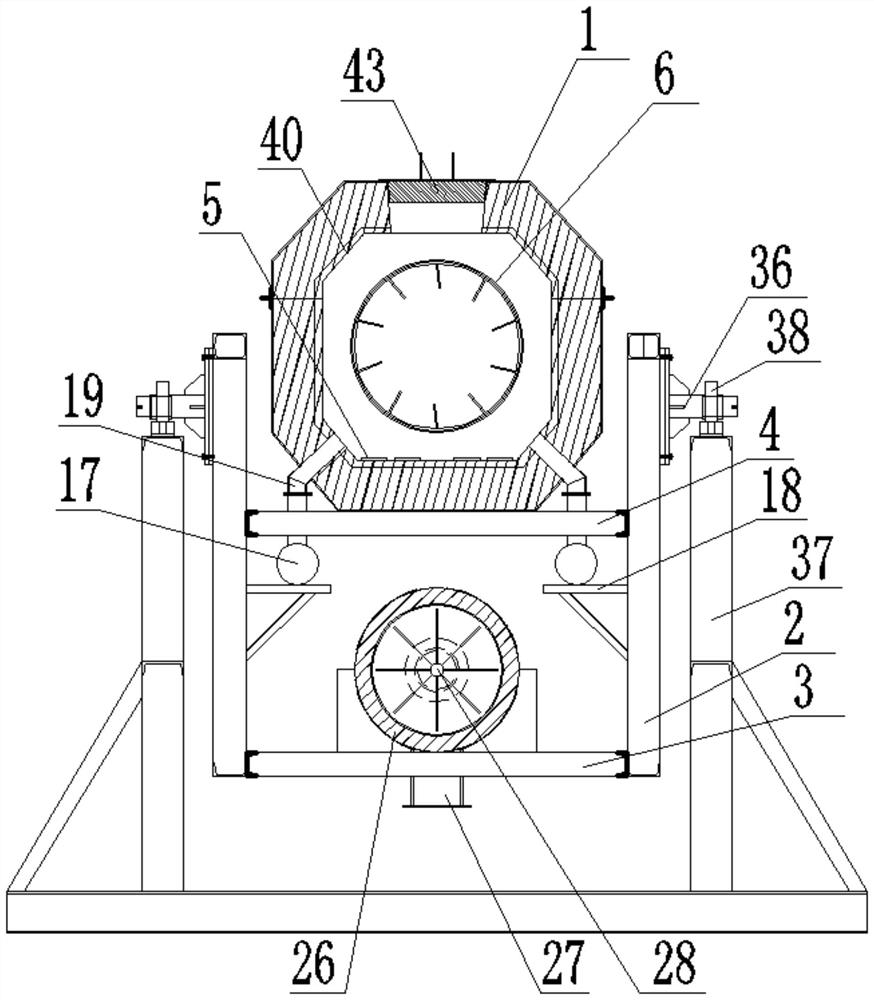

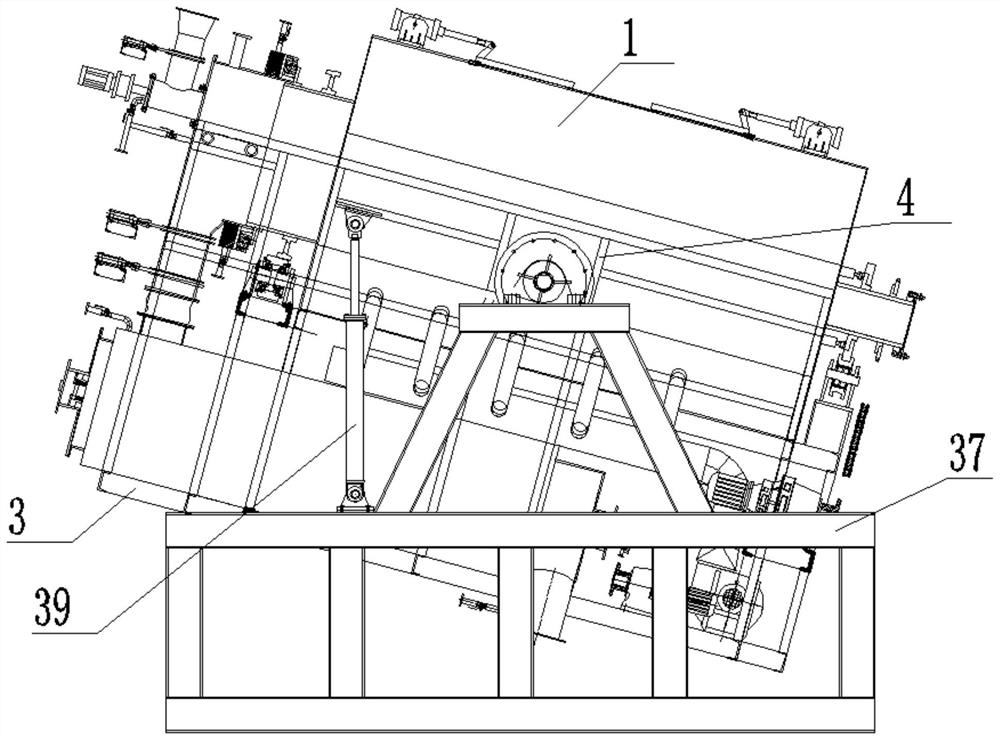

Direct air cooling method for shifted gas

ActiveCN111678358ALow thermal conductivityImprove thermal conductivityCorrosion preventionStationary conduit assembliesCirculator pumpCooling effect

The invention provides a direct air cooling method for shifted gas. High-temperature wet shifted gas is directly sent to air cooling fin tube bundles; shifted gas condensate is sent to the inlet of each fin tube through a circulation pump and a water spray pipe; and by utilizing the characteristic that high-frequency turbulent flow and water brought by high-speed air flow are far higher than the shifted gas in heat conductivity, the film coefficient of heat transfer of the inner wall of the air cooling fin tubes is greatly increased, thereby improving the air cooling effect of the shifted gas,greatly reducing consumption of water resources and power consumption of a fan, and guaranteeing the effect of directly cooling the shifted gas by using air.

Owner:四川省简阳空冷器制造有限公司 +2

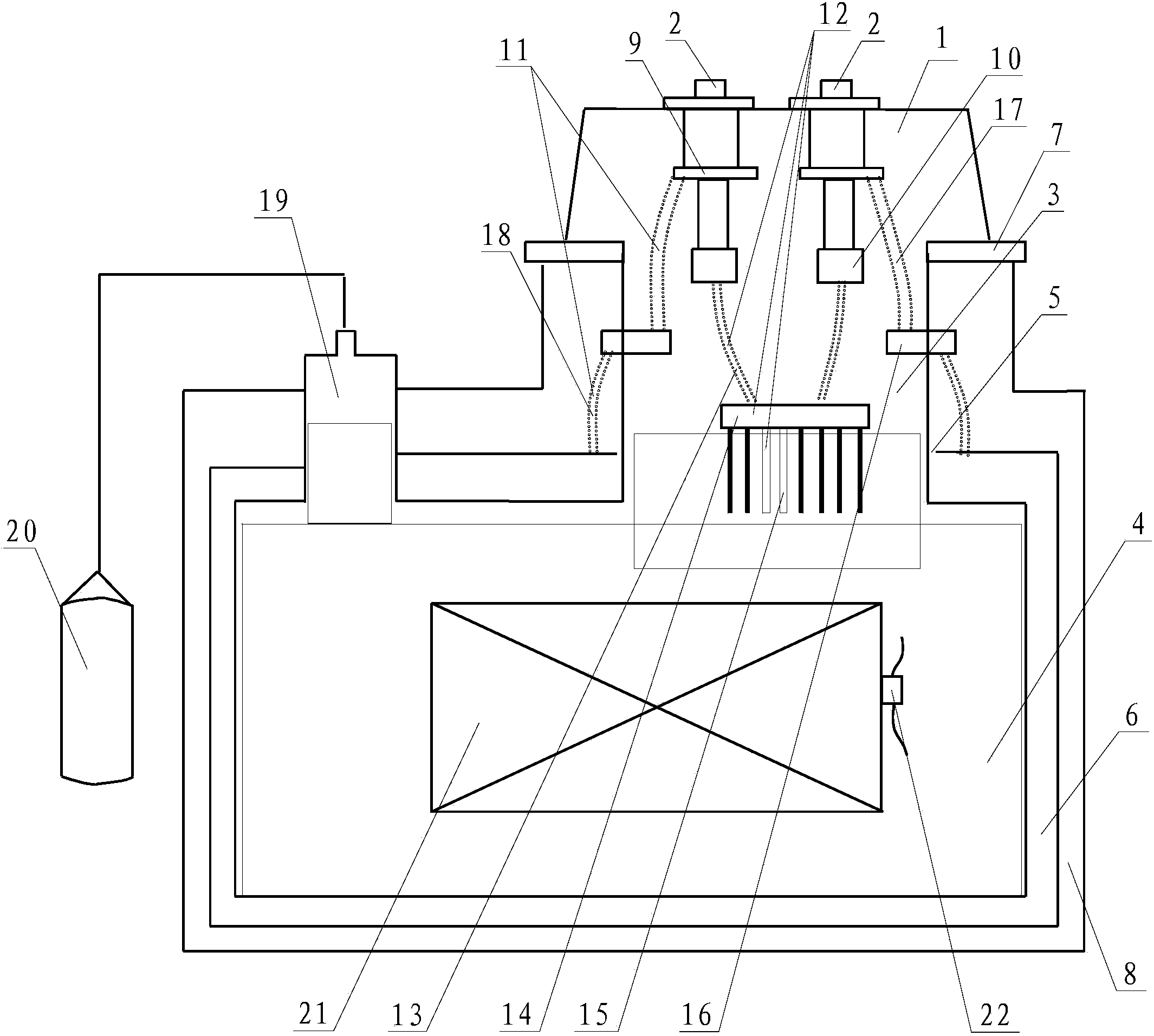

A fully automatic periodic drum resistance furnace

The invention discloses a fully automatic periodic roller resistance furnace, which comprises a furnace body, side plates are arranged on both sides of the furnace body, a bottom plate is fixed between the lower ends of the side plates, and a bottom plate is fixed between the middle parts of the side plates. There is a partition, the furnace body is fixed on the partition, the inner wall of the furnace is fixed with a heating element, the furnace body is provided with a retort, one end of the retort is provided with a discharge bin and the furnace The tank and the discharge bin are rotatably connected to the discharge bin through a graphene rotating bearing, and a drive shaft is fixed at one end of the retort away from the discharge bin, and the drive shaft extends out of the furnace body and The outer wall fixing sleeve is provided with a limiting plate and a first sprocket. Beneficial effects: the raw material can be directly cooled, and the furnace tank can be quickly cooled in an emergency, so that the cooling process can be simplified, the production efficiency is high, and the equipment is small in size and weight, which is beneficial to cost reduction and easy to use.

Owner:江苏新江南炉业科技有限公司

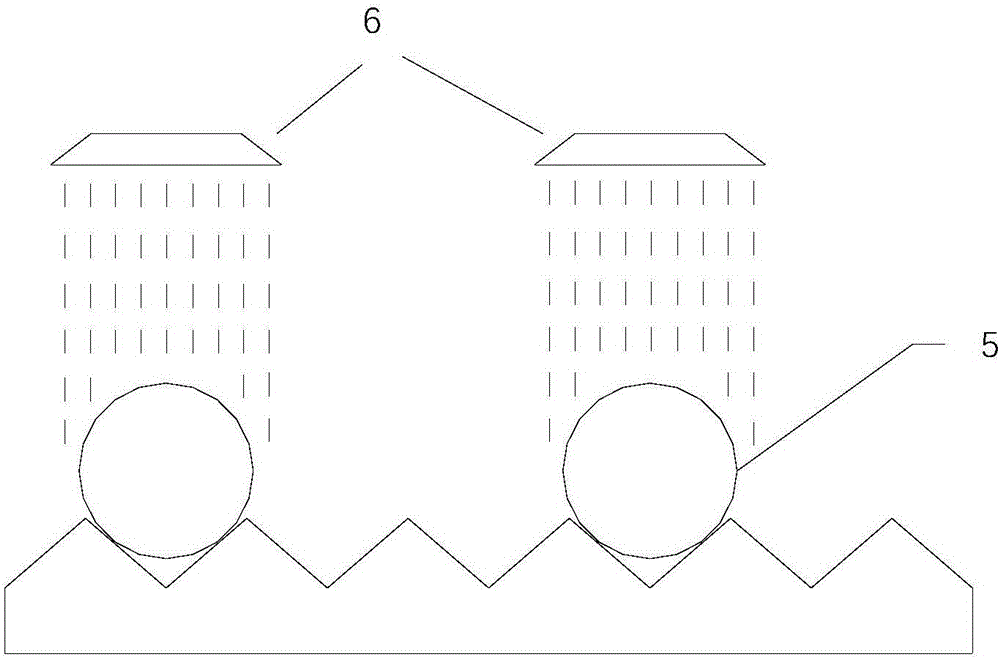

Double-sided conduction cooling multi-sheet laser head

InactiveCN111431019ASimple cooling processCompact structureActive medium shape and constructionLaser cooling arrangementsEngineeringConduction cooling

The embodiment of the invention provides a double-sided conduction cooling multi-sheet laser head. The double-sided conduction cooling multi-sheet laser head comprises a gain medium, a heat sink, a cooling metal, a first contact object between the gain medium and the heat sink, and a second contact object between the heat sink and the cooling metal. Both the gain medium and the heat sink are sheet-shaped and are separately arranged in parallel at intervals. The cooling metal is arranged at the peripheries of the gain medium and the heat sink, the cooling temperature is constant, and the centers of the gain medium and the heat sink are coaxial. The plane of the gain medium is vertical to the central axis, the edge of the gain medium is connected with the edge of the heat sink through the first contact object, and the edges of the two surfaces of the heat sink are connected with the inner wall of the cooling metal through the second contact object. The double-sided conduction cooling multi-sheet laser head provided by the embodiment of the invention has the advantages that the gain medium has no special requirements for gradual change, interval or gradient doping and the like, the cooling action process is simple, the structure is compact, and the heat dissipation effect is good, and the high-power output of a multi-sheet laser is facilitated.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Thermosiphon Oil Cooling System

ActiveCN104567060BEfficient use ofSave energyMechanical apparatusCompression machines with non-reversible cycleThermodynamicsEngineering

The invention discloses a thermosiphon oil cooling system, which comprises a thermosiphon liquid storage device, a condenser and a high-pressure liquid storage device, and also includes a liquid outlet pipe of the condenser and an overflow pipe of the thermosiphon liquid storage device. The thermosiphon liquid storage device The overflow port of the condenser and the high-pressure liquid reservoir are connected through the overflow pipe of the thermosiphon liquid reservoir. One end of the condenser liquid outlet pipe is connected to the liquid outlet of the condenser, and the other end is connected to the overflow pipe of the thermosiphon liquid reservoir. Tube. The thermal siphon oil cooling system of the present invention has the advantages of simple structure, convenient modification, safety and reliability, and energy saving.

Owner:SINOHYDRO BUREAU 8 CO LTD

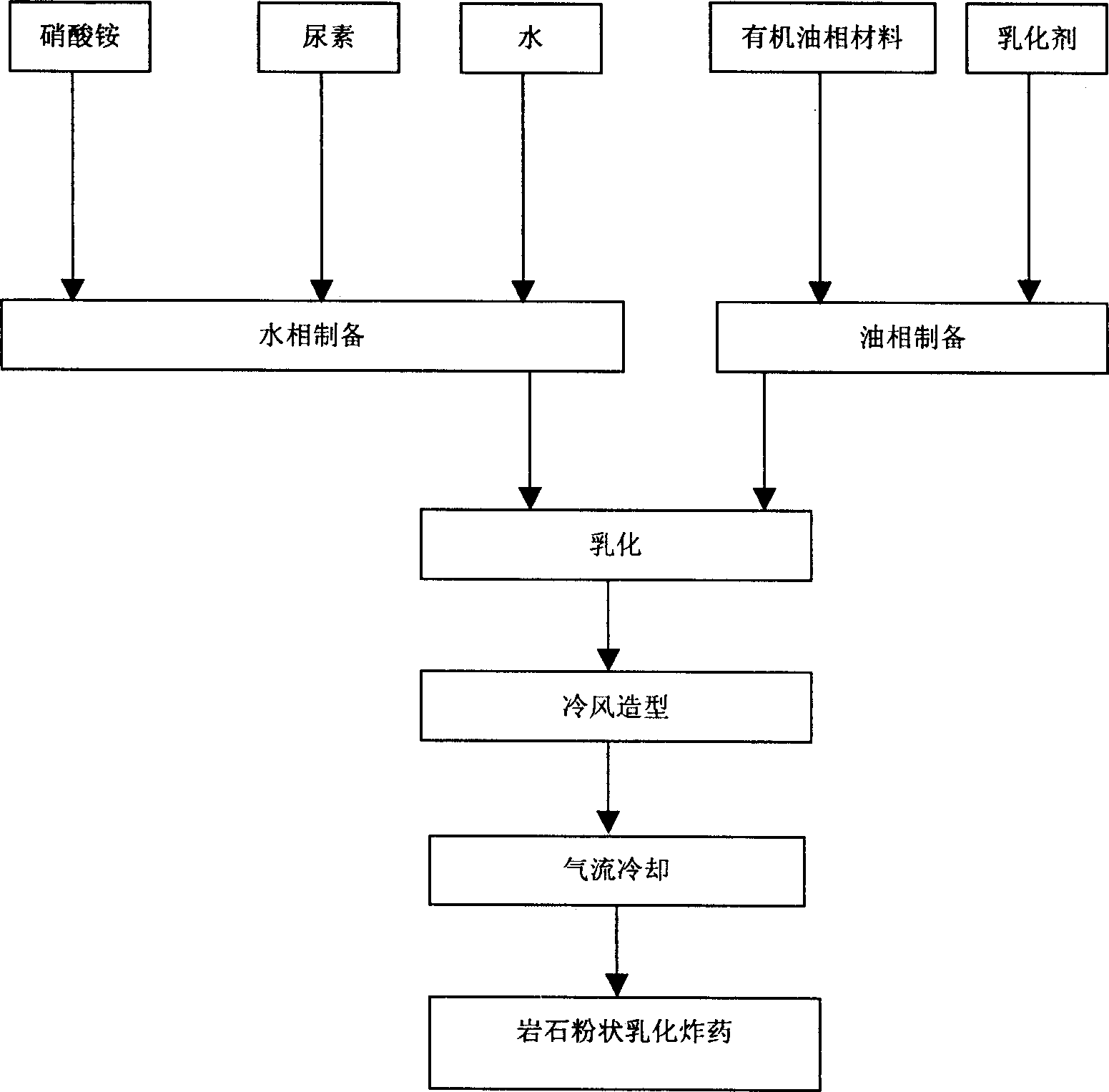

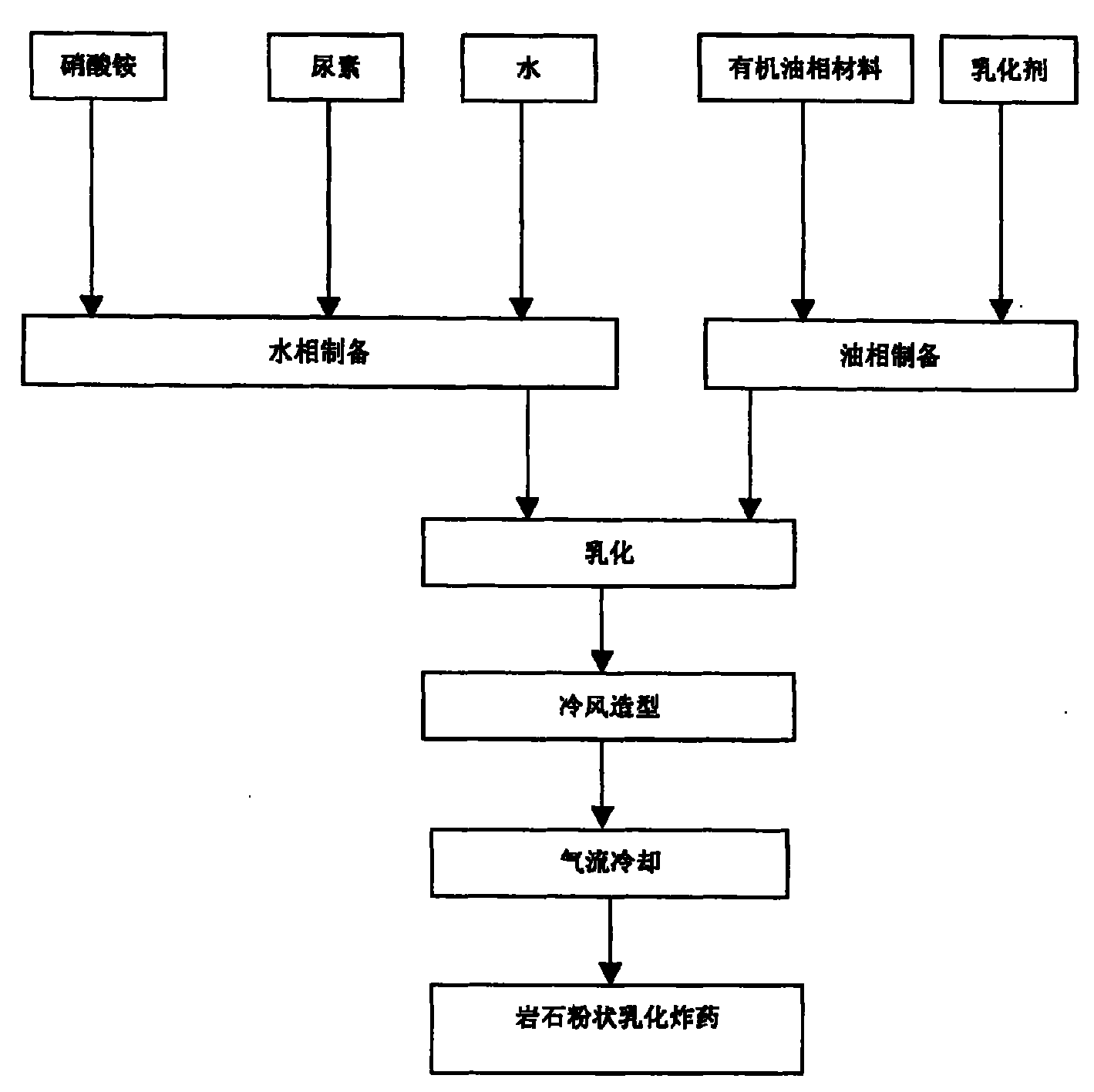

Rock powder shaped emulsion explosive and manufacturing method thereof

InactiveCN1263709CGood storage stabilityLow costExplosive working-up apparatusNon-explosive/non-thermic compositionsCold airEmulsion explosive

The invention relates to a rock powder shaped emulsion explosive and manufacturing method thereof, wherein the explosive comprises (by wt. portions) ammonium nitrate 87-93, assisting solvent 1-3, organic oily phase material 4-6, macromolecular emulsifying agent 1-3, and water 1-5. The preparation process comprises the steps of, charging aqueous phase into agitated oily phase, emulsifying into water-in-oil type emulsion, and making emulsion rock powdery explosive through cold air blast modeling.

Owner:SHANXI TOND CHEMICAL CO LTD

A kind of acid corrosion resistant martensitic wear-resistant steel plate and its manufacturing method

ActiveCN111575581BGuaranteed corrosion resistanceImprove mechanical propertiesFurnace typesHeat treatment furnacesAcid corrosionHardness

The application discloses an acid-resistant martensitic wear-resistant steel plate, which includes 0.14wt%≤C≤0.22wt%; 0.30wt%≤Si≤0.60wt%; 0.30wt%≤Mn≤1.00wt% in mass percentage; 0.010wt%≤Ti≤0.020wt%; 0.02wt%≤Nb≤0.04wt%; 0.50wt%≤Ni≤1.0wt%; 0.20wt%≤Cu≤0.50wt%; 0.9wt%≤Cr≤1.3wt%; 0.08wt%≤Sb≤0.12wt%; 0.0010wt%≤B≤0.0020wt%; 0<S≤0.003wt%; 0<P≤0.012wt%; Issues of hardness, plasticity, toughness, wear resistance and corrosion resistance.

Owner:湖南华菱涟源钢铁有限公司 +3

Method for controlling reticular carbide in bearing steel bar and device for implementing the method

ActiveCN105817487BInhibition formationReduce manufacturing costTemperature control deviceCooling bedsCarbideSlow cooling

The invention discloses a control method for bearing steel bar network carbide and a device for implementing the method. The control method comprises the following steps that the finish rolling temperature of a bearing steel bar with the diameter being phi 20-60 mm is controlled to be 940-1000 DEG C, and the cooling speed of the bearing steel bar is controlled through a double-cooling-area cooling mode after rolling; double cooling areas include the cooling bed quick water cooling area and the cooling bed re-reddening slow cooling area; during the process in the cooling bed quick water cooling area, after rolling, the high-temperature bearing steel bar is fed into the cooling bed quick water cooling area from a cooling bed entry table, and the surface temperature of the bearing steel bar is controlled to be rapidly decreased to 400-450 DEG C through water cooling; during the process in the cooling bed re-reddening slow cooling area, when the temperature of the core part of the bearing steel bar fed into the re-reddening slow cooling area is higher than the surface temperature, heat diffuses from interior to exterior, the bearing steel bar starts to re-redden, the surface temperature is raised to 600-650 DEG C, and then the bearing steel bar is slowly cooled to 150-300 DEG C in the air. The structure grade of the network carbide is controlled within the 1.0 grade.

Owner:SHANDONG IRON & STEEL CO LTD

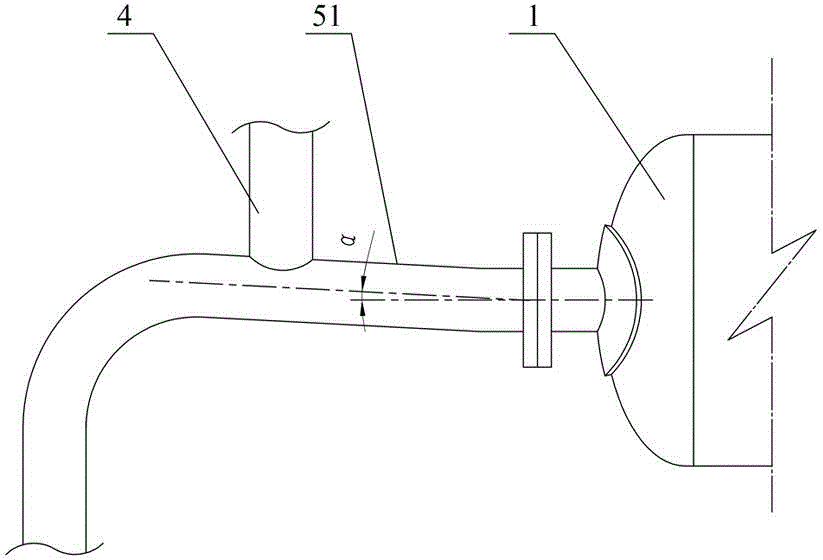

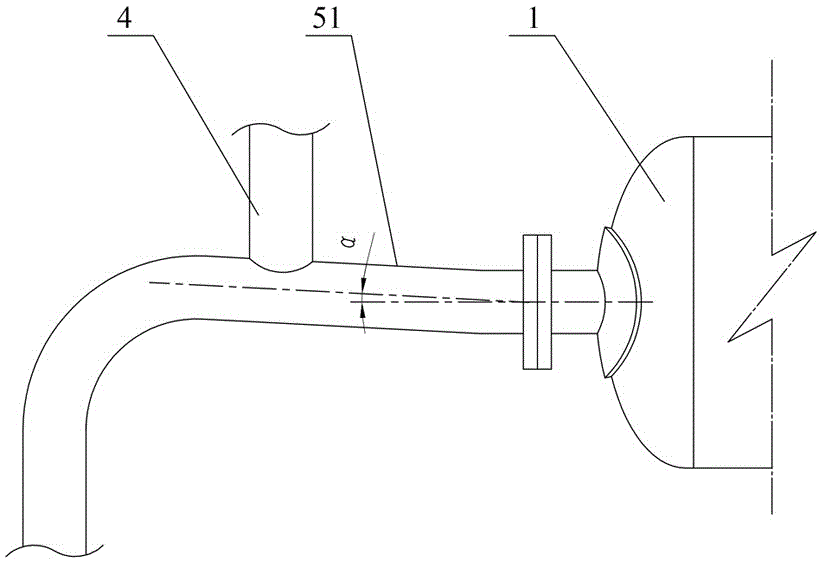

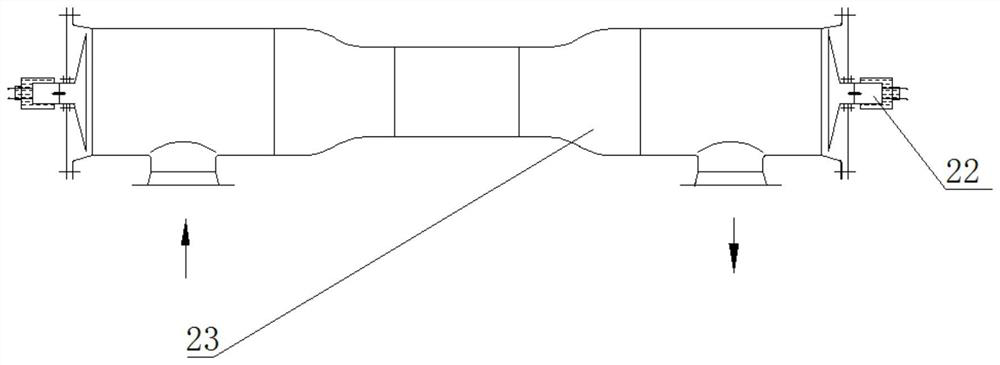

Cooling device and method for fin type industrial magnetostrictive type ultrasonic transducer

PendingCN111974659AAchieve isolationMeet the site requirements for fire and explosion protectionDomestic cooling apparatusLighting and heating apparatusEngineeringCooling fluid

The invention relates to the technical field of ultrasonic transducers, in particular to a cooling device and method for a fin type industrial magnetostrictive type ultrasonic transducer. The coolingdevice for the fin type industrial magnetostrictive type ultrasonic transducer comprises a transducer cavity, a wiring cavity, a coil winding, a magnetostrictive material and a vibrator block, whereinthe coil winding and the magnetostrictive material are integrally positioned inside the transducer cavity and the vibrator block is partially positioned in the transducer cavity; a transducer cavityhousing of the transducer cavity is a cylindrical structure with fins; one end of the cylindrical cavity is equipped with the vibrator block, and the other end of the cylindrical cavity is equipped with an upper cover plate, and the residual space inside is filled with quartz sand; and the free end of the magnetostrictive material is coated with a sound-absorbing material layer. The cooling deviceand method for the fin type industrial magnetostrictive type ultrasonic transducer disclosed by the invention avoids a leakage problem which possibly appears by adopting a cooling water or cooling liquid cooling way, reduces production and management cost, and ensures long-period stable work of the industrial ultrasonic transducer.

Owner:QINGDAO BESTSONIC TECH CO LTD

An activated carbon treatment system for improving waste heat utilization rate and denitrification rate and its application method

ActiveCN108939808BGuaranteed temperatureImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationActivated carbonFlue gas

The invention provides an activated carbon treatment system for improving waste heat utilization rate and denitration rate and a using method thereof. Heat exchangers are separately disposed before flue gas is input into a first-stage adsorption column and a second-stage adsorption column, the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column is controlled, thereby ensuring the temperature of desulfurization and denitration. The activated carbon treatment system utilizes high-temperature flue gas (about 150-170 DEG C) after a main exhaust blower, adopts a mode of heat exchange, artificially controls the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column, and enables the efficiency of removal of SO<2> and NO<x>; and the utilization rate of the high-temperature flue gas after the main exhaust blower is increased, and the temperature of the flue gas entering a desulfurization tower and a denitration tower is controlled to improve the efficiency of desulfurization and denitration.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A kind of atmospheric corrosion resistant martensitic wear-resistant steel plate and its manufacturing method

This application belongs to the technical field of iron and steel metallurgy, and in particular relates to a martensitic wear-resistant steel plate resistant to atmospheric corrosion, including 0.14wt%≤C≤0.22wt%; 0.30wt%≤Si≤0.60wt%; 0.30wt% %≤Mn≤1.00wt%; 0.010wt%≤Ti≤0.020wt%; 0.02wt%≤Nb≤0.04wt%; 0.50wt%≤Ni≤1.0wt%; 0.20wt%≤Cu≤0.50wt%; 3.4wt% %≤Cr≤4.0wt%; 0.0010wt%≤B≤0.0020wt%; 0<S≤0.003wt%; 0<P≤0.012wt%; The corroded martensitic wear-resistant steel plate can take into account the hardness, plasticity, toughness, wear resistance and corrosion resistance of the steel plate.

Owner:湖南华菱涟源钢铁有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com