Steel for ultra-high-strength sucker rod and production method thereof

A technology of ultra-high strength and manufacturing method, applied in the field of alloy steel, can solve the problems of high process cost, insufficient corrosion resistance, difficult to meet the requirements of oil wells, etc., and achieve the effect of simple cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The embodiment of the present invention provides four kinds of steels for sucker rods, and the four kinds of steels for sucker rods are respectively marked as 1#, 2#, 3# and 4#, and the main chemical compositions of the four kinds of steels for sucker rods are shown in the table 1, each element composition is in line with the scope of the present invention. Its manufacturing method comprises the following steps:

[0045] (1) Smelting: adopt ultra-clean steel smelting technology: use converter to smelt molten steel, blow nitrogen at the bottom, and control the intensity of the low-blowing nitrogen to 0.05-0.3m 3 / (min t); respectively control the binary basicity, total Fe and temperature of the slag at the early stage of smelting and the end point of smelting, wherein the binary basicity of the slag at the early stage of smelting is 1.8-2.2, and the total Fe is 12-22% , the temperature is 1340~1410℃; the binary basicity of the slag at the end of smelting is 2.0~4.0, the...

Embodiment 2

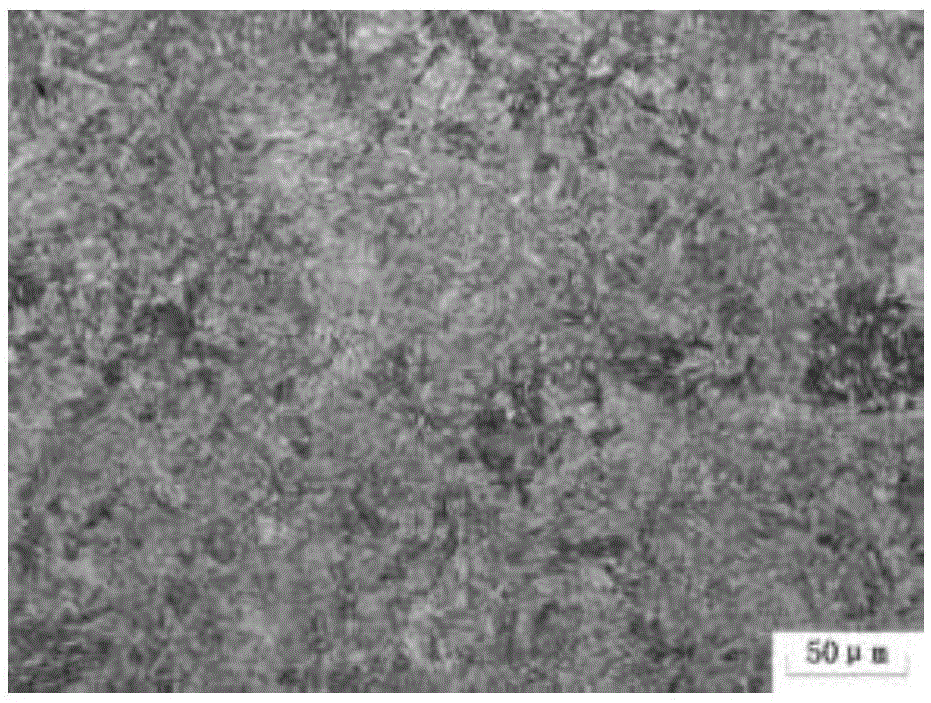

[0069] 1# round steel of the present invention carries out microstructure experiment, the experimental condition of OM: adopt 3% nitric acid alcohol solution to etch after 1# round steel sample is mechanically polished, observe 1# round steel respectively at Zeiss40MAT digital metallographic microscope Microscopic OM photographs, such as figure 1 As shown, it can be seen that the structure of 1# round steel of the present invention is a high temperature tempered martensitic structure;

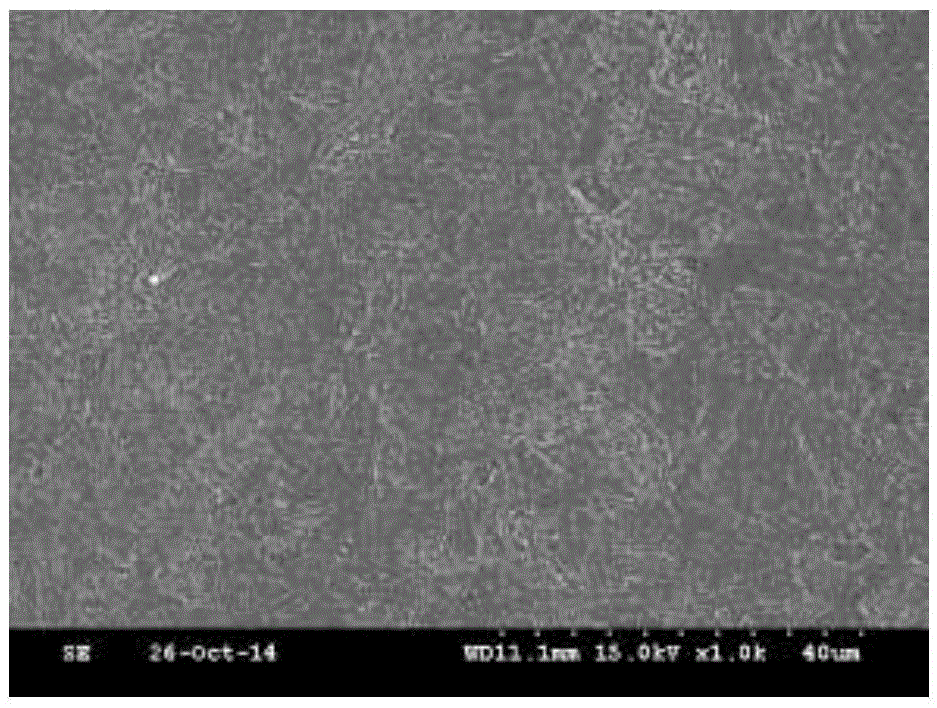

[0070] Experimental conditions of SEM: the 1# round steel sample is etched with 3% nitric acid alcohol solution after mechanical polishing, and then the microscopic SEM photos of 1# round steel are observed under the Japanese Hitachi S-4300 scanning electron microscope, as figure 2 As shown, it can be seen that the structure of 1# round steel of the present invention is a high temperature tempered martensitic structure;

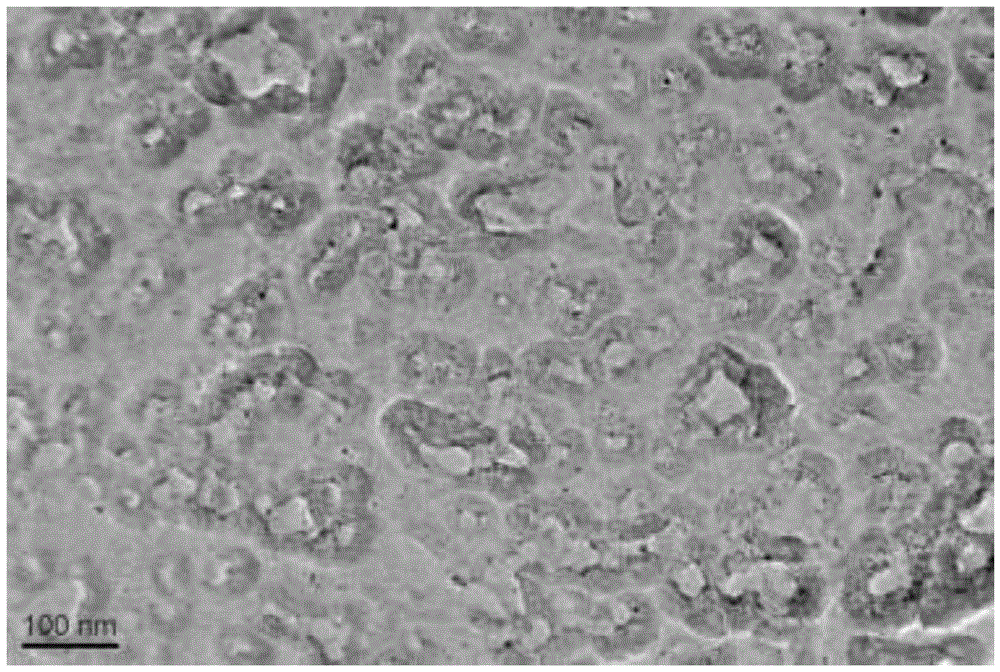

[0071] Experimental conditions for TEM and EDS: corrode the 1# round st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com