Method for controlling reticular carbide in bearing steel bar and device for implementing the method

A technology of reticulated carbide and control method, applied in the direction of temperature control, metal rolling, manufacturing tools, etc., can solve the problems of limited degree of carbide segregation, high energy consumption, burning loss of casting billet, etc. The formation of tissue, the simple cooling process, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

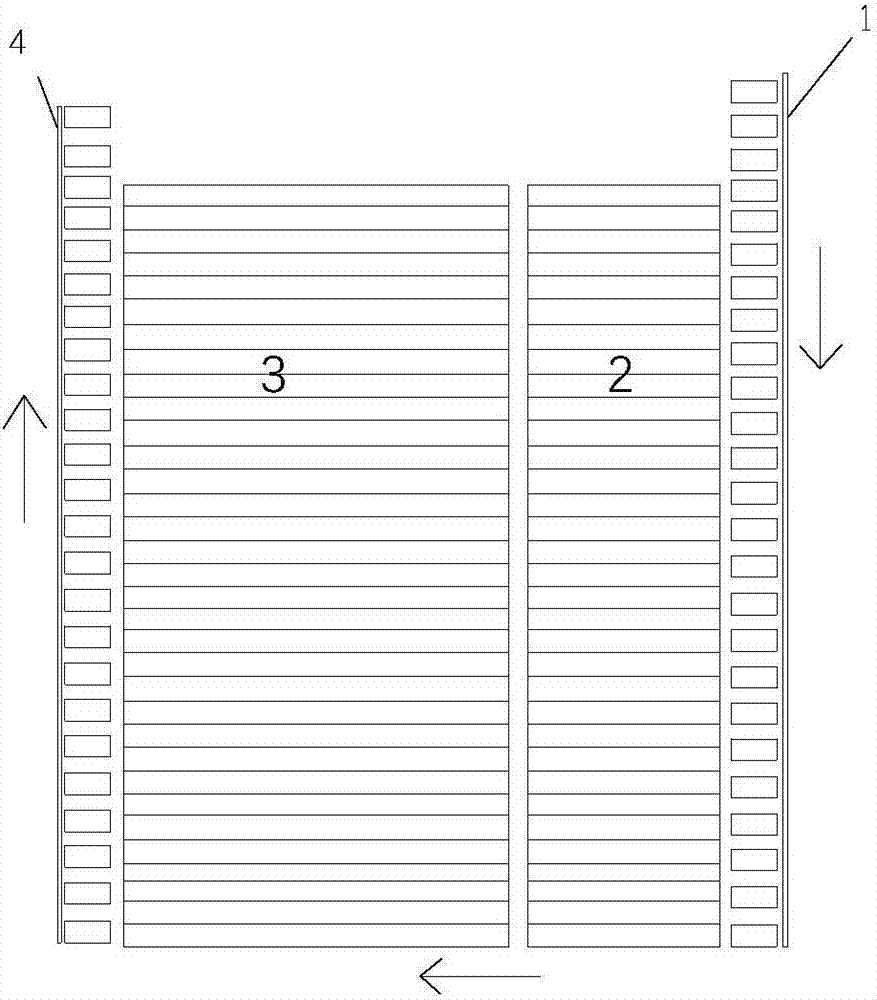

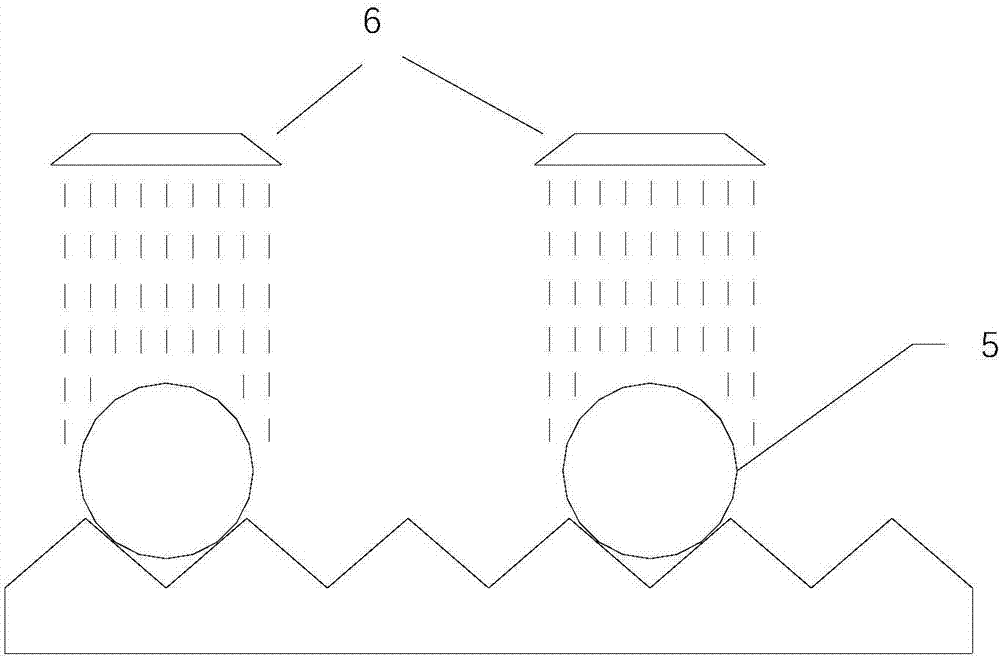

[0032] In this embodiment, the specification of the continuous casting slab is 180 mm×220 mm, and the rolling specification is Φ20 mm. The final rolling temperature is 940-980°C. first after rolling figure 1 After the shown cooling bed input roller table 1 reaches the receiving station of the cooling bed rapid water cooling zone 2, it is translated to the cooling bed rapid water cooling zone 2, and the cooling water in the cooling water pipe 6 performs forced rapid water cooling on the bearing steel bar 5 (Rapid water cooling from 940 to 980°C to 400 to 450°C can effectively suppress the precipitation of network carbides at the austenite grain boundaries), the cooling rate is about 40°C / S, and the water cooling time is about 13s until the surface temperature of the bearing steel reaches 400~ After 450°C, the temperature sensor on the rapid water cooling zone 2 of the cooling bed receives the temperature signal and transmits the temperature signal to the control system. Go to...

Embodiment 2

[0034] In this embodiment, the specification of the continuous casting slab is 180 mm×220 mm, and the rolling specification is Φ40 mm. The final rolling temperature is 950-990°C. first after rolling figure 1After the shown cooling bed input roller table 1 reaches the receiving station of the cooling bed rapid water cooling zone 2, it is translated to the cooling bed rapid water cooling zone 2, and the cooling water in the cooling water pipe 6 performs forced rapid water cooling on the bearing steel bar 5 (Rapid water cooling from 950 to 990°C to 400 to 450°C can effectively suppress the precipitation of network carbides at austenite grain boundaries), the cooling rate is about 35°C / S, and the water cooling time is about 16s until the surface temperature of the bearing steel reaches 400~ After 450°C, the temperature sensor on the rapid water cooling zone 2 of the cooling bed receives the temperature signal and transmits the temperature signal to the control system. Go to the ...

Embodiment 3

[0036] In this embodiment, the specification of the continuous casting slab is 180 mm×220 mm, and the rolling specification is Φ60 mm. The final rolling temperature is 960~1000℃. first after rolling figure 1 After the shown cooling bed input roller table 1 reaches the receiving station of the cooling bed rapid water cooling zone 2, it is translated to the cooling bed rapid water cooling zone 2, and the cooling water in the cooling water pipe 6 performs forced rapid water cooling on the bearing steel bar 5 (Rapid water cooling from 960~1000℃ to 400~450℃ can effectively suppress the precipitation of network carbides at the austenite grain boundary), the cooling rate is about 30℃ / S, and the water cooling time is about 20s until the surface temperature of the bearing steel reaches 400~ After 450°C, the temperature sensor on the rapid water cooling zone 2 of the cooling bed receives the temperature signal and transmits the temperature signal to the control system. Go to the slow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com