Integration installation for producing synthesis gas from coal with high volatile constituent

A coal-to-synthesis gas and integrated device technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of unrecoverable coal tar chemical products, frequent equipment maintenance, complicated gas purification and wastewater treatment, etc., and achieve the reduction of phenols Sewage, cooling process simplification, operation cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

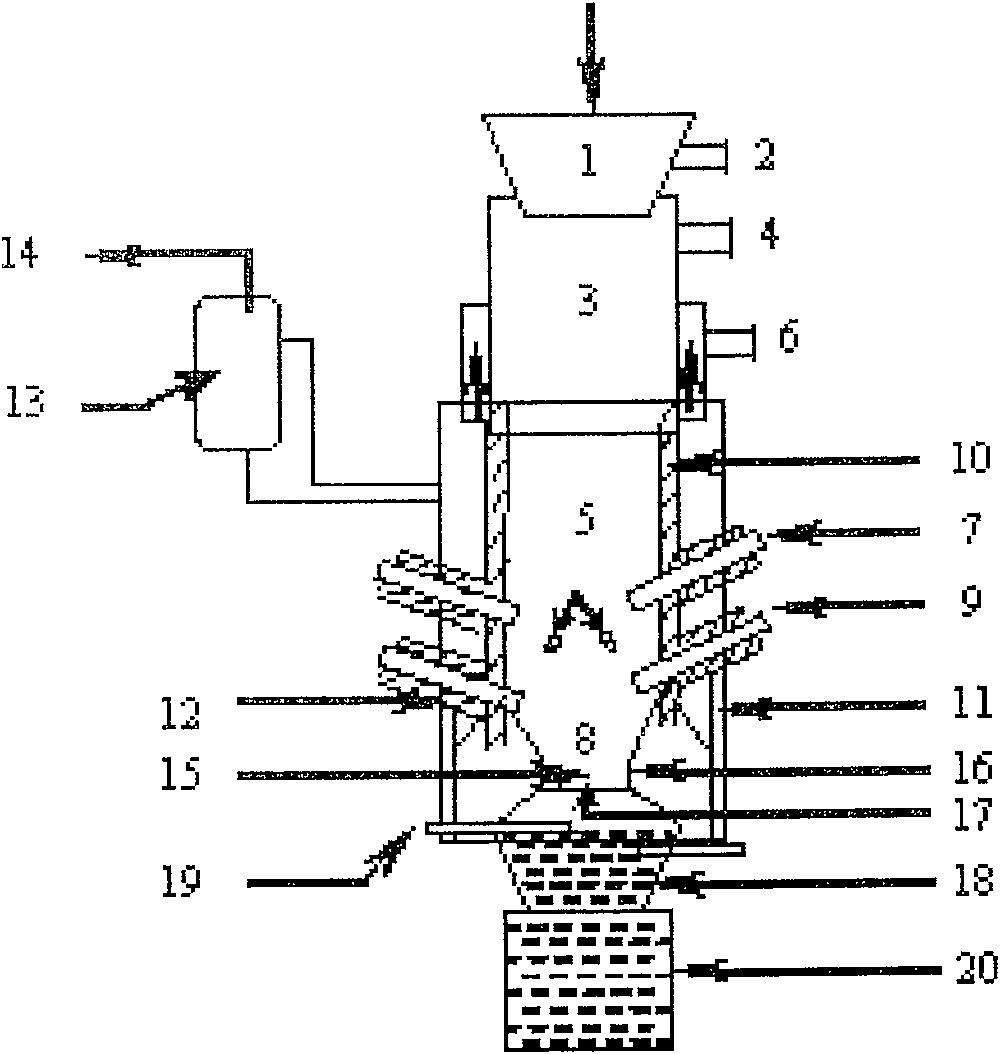

[0043] The device of the present invention is described in detail below in conjunction with accompanying drawing as follows:

[0044] The high volatile coal-to-synthesis gas integration device of the present invention adopts a three-stage structure, as shown in the figure, the upper part is the drying and distillation section of coal material, the middle part is the conversion section for converting pyrolysis gas into synthesis gas, and the lower part is the char gas after carbonization. The gasification section, and the bottom is the slag discharge section of gasification ash. The top of the dry distillation section 3 is provided with a raw material coal screening storage device 1 with a sealed structure, and is provided with a pulverized coal outlet 2, a pyrolysis gas outlet 4 and a synthesis gas outlet 6, and the lower part passes through the carbonization chamber and the conversion section 5 and the gasification The sections 8 are connected; the inner wall of the conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com