Novel active carbon analysis tower and active carbon analysis process

A technology of activated carbon and analytical tower, applied in the field of sintering flue gas treatment, can solve the problems of high moisture content, high heat and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

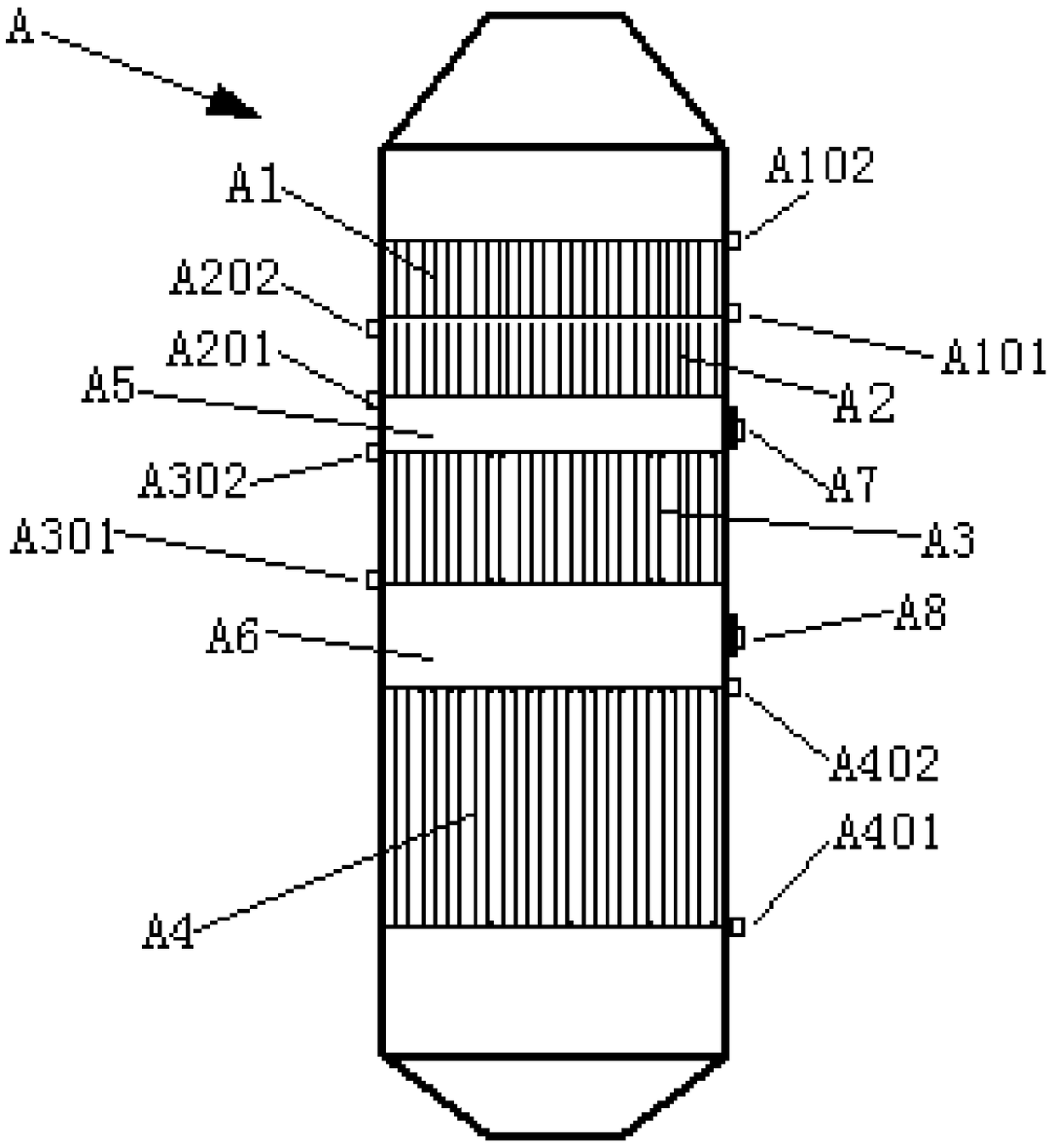

[0089] Such as figure 1 As shown, a new type of activated carbon desorption tower, the activated carbon desorption tower A includes preheating zone A1, water vapor decomposition zone A2, pollutant decomposition zone A3, cooling zone A4, first transition section A5 and the second Two transition section A6. The lower part of the preheating zone A1 is provided with a preheating zone gas inlet A101 and a preheating zone gas outlet A102. The lower part of the water vapor decomposition zone A2 is provided with a water vapor decomposition zone gas inlet A201 and a water vapor decomposition zone gas outlet A202. The lower part of the pollutant decomposition zone A3 is provided with a gas inlet A301 for the pollutant decomposition zone and a gas outlet A302 for the pollutant decomposition zone. The lower part of the cooling zone A4 is provided with a cooling zone gas inlet A401 and a cooling zone gas outlet A402. The first transition section A5 is between the water vapor decompositi...

Embodiment 2

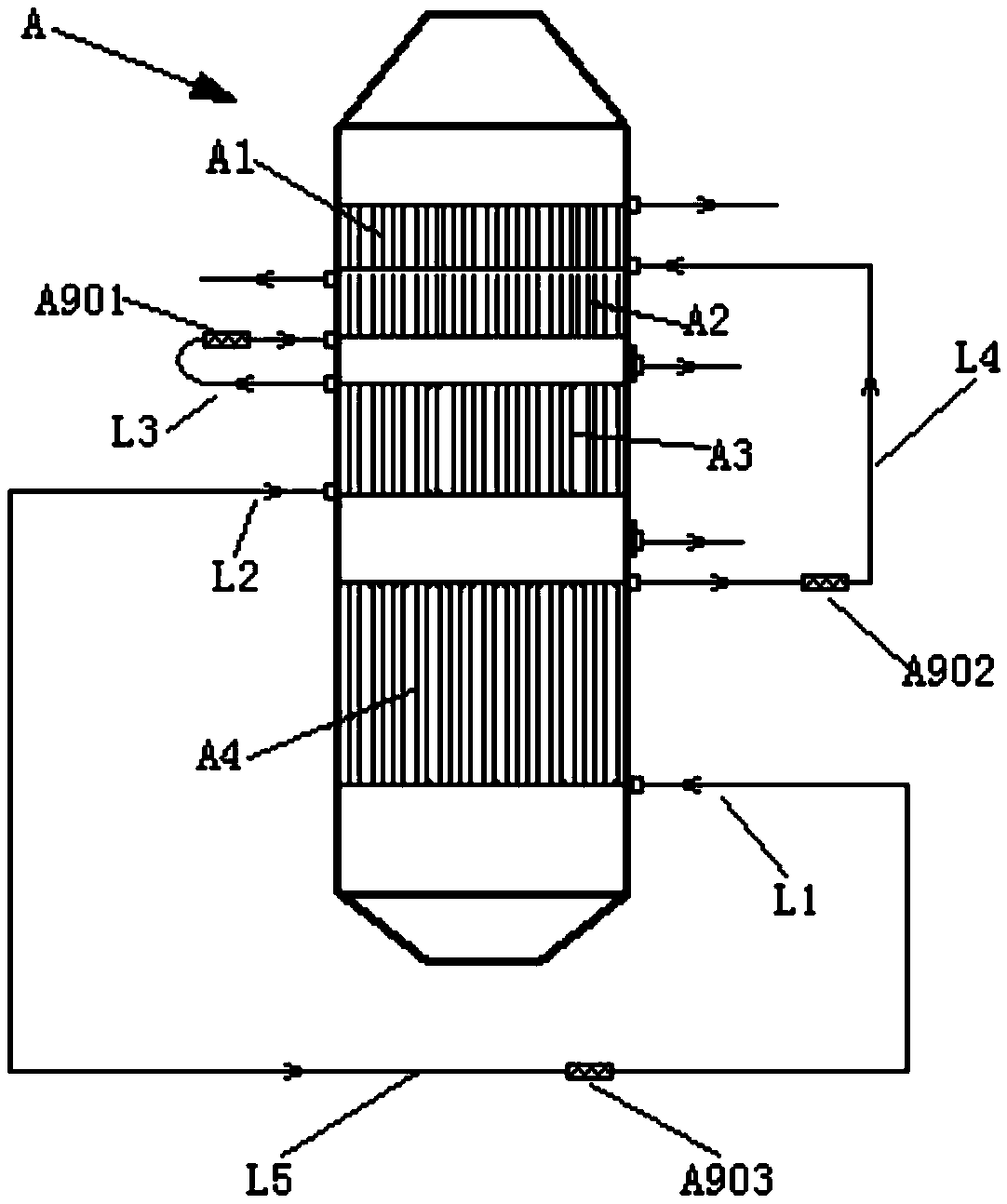

[0091] Such as figure 2 As shown, Example 1 is repeated, except that the gas outlet A302 of the pollutant decomposition zone is connected to the gas inlet A101 of the preheating zone through the first delivery pipeline L3. The gas outlet A402 of the cooling zone is connected to the gas inlet A101 of the preheating zone through the second delivery pipe L4. The gas outlet A202 of the water vapor decomposition zone is connected to the gas inlet A101 of the preheating zone through the third delivery pipeline L5.

Embodiment 3

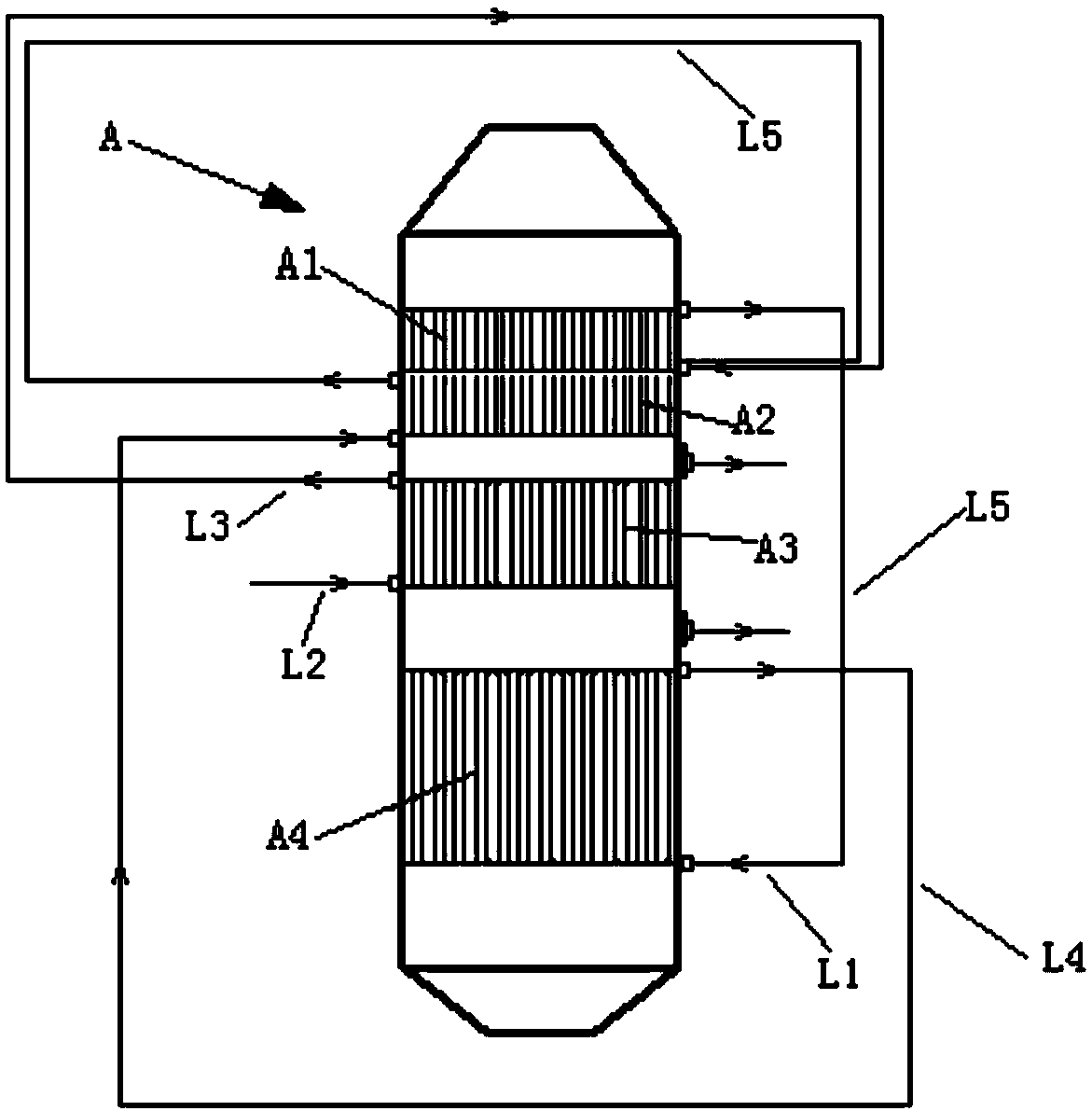

[0093] Repeat Example 2, except that the gas outlet A402 of the cooling zone is connected to the gas inlet A201 of the water vapor decomposition zone through the second delivery pipeline L4. The gas outlet A202 of the water vapor decomposition zone is connected to the gas inlet A401 of the cooling zone through a third delivery pipeline L5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com